Better Sailing

Best Tapes for Sail Repair

Is your sail suddenly ripped? Are you looking for the best tape for sail repair? Then this article will guide you through your purchase. Remember to always stock onboard your sails repair kit and like this, you’ll set sail free of worries! Also, equip your sails repair kit with high-quality maintenance and repair tools, tapes, and materials. There are a lot of different types of tapes in the market that can be used to repair Dacron, Ripstop, canvas, vinyl, rubber, and more sail fabrics. Tapes are particularly helpful if you want to quickly repair your sails while you’re cruising, along with the help of Dacron or Ripstop sailcloth. Keep in mind that most of the tapes are designed for emergency and temporary repairs. In case you want to ensure permanent patching then consider having onboard a sail and canvas repair kit.

Sail Repair Tape Types

- Main Tales : Like tell-tales that fit genoa luffs these tapes should be fitted at intervals along the leech of the mainsail. In this way, you’ll be able to trim the mainsail when sailing upwind or on a reach.

- Dacron Insignia Cloth : For making repairs or adding insignia to high load sail areas and covers.

- Dacron Sail Repair Patch : These are available in different colors. They contain two sailcloth patches for application to either side of the sail for a larger repair.

- Dacron Wave Leech Tape : This is an adhesive Dacron cloth edging that is manufactured in order to reduce flutter and breakdown to the leech of the mainsail. Moreover, the tape becomes waterproof approximately within an hour at room temperature when the adhesive has set.

- Anti Chafe Roll or Patch : With these, you can prevent damage to the paint, gel coat, and reduce friction on areas of contact with sails, blocks, and ropes. An Anti-chafe patch can be used around cleats or fairleads or you can even apply it to a keelboat or dinghy spinnaker chute for friction-free hoists. It protects vulnerable areas and it doesn’t detract from the total visual effect of any surface. It has waterproof glue and strong adhesion, good temperature resistance, and excellent longevity.

- Rig Wrap : Coil the clear tape around rigging in places where the sails come in touch. Also, it provides a friction-free surface to facilitate the passage of sails when tacking and gybing.

- Spinnaker Repair Tape : This tape is perfect for emergency spinnaker and kite repairs. They can also prevent any further damage and they keep you safe on the water before making a permanent repair.

- Kevlar Sail Repair Tape/Patch : A high performance and emergency Kevlar/Mylar laminate tape for strong repairs to racing sails. The Kevlar patch contains 2 strong kevlar patches to apply on either side when repairing a laminate racing sail.

- Mylar Repair Tape : This is a transparent, high clarity UV and saltwater resistant tape for repairs to sail windows and mylar sails.

- Tell Tales : These are designed for upwind sailing. When the sail is trimmed correctly the leeward tell-tale should stretch evenly backward and the windward tell-tale should be slightly lifted.

- Heavy Duty Sail Repair Tape : This is an adhesive polyamide fabric sail repair tape. It is resistant to seawater and to various weather conditions.

- Kite Tape : A tear-resistant adhesive rip-stop nylon that comes in many different colors and within a roll of 150mm width. It is the best emergency solution if you notice a small tear in your sail or kite.

Best Sail Repair Tapes

Land n sea clear ultra strong – best sail repair tape.

Highly resistant to tearing, weather conditions, and a super-strong adhesive that even works on damp sails. Its transparent color is suitable for any sail and the tape is lightweight, flexible, and very strong. I used this tape for a rip in my sail a couple of years ago and they are still going strong. To use this tape, clean the area well with alcohol then cut two identical patches, and put one on each side. It works great. I couldn’t recommend this product enough. Check the price on Amazon .

Transparent Duct Tape for Sail Repair

A 100% waterproof and weather-resistant tape that repairs almost everything on your sails. Also, it is strong and it comes in different widths to cater to your individual repair needs. The company also offers a 100% satisfaction guarantee and will issue you an immediate refund if their product doesn’t work for its intended purposes. The adhesiveness is excellent. All the areas I taped with this are nice and tight, with no tape coming off. This is a cheaper option but it is a very versatile tape that you should have onboard anyway. Check out the price .

Gorilla Crystal Clear Duct Tape

It’s made with a particularly strong adhesive layer that ensures the tape’s durability. It’s also waterproof and UV/temperature resistant. To achieve the best results, clean the sails thoroughly with soap, let it dry and then use tape on both sides of the sail. Link to Amazon .

Premium Grade Gaffer Tape

A tough and powerful tape with excellent flexibility and adhesion to ensure the best performance for small or big sail repairs as well as for surface protection. I personally don’t prefer this tape because if your sails are white the patch will look sloppy with this black tape. However, if you do not care about how it looks and only care about the repair then this tape won’t let you down. However, I still do recommend the first tape on this list.

Awning Repair Tape

Are you looking for a permanent repair tape for rips and punctures? Then this tape will do the job! It has a strong adhesive that resists tearing in any direction, a long life spanning, multiple-use tape, and 100% water-resistant. I haven’t personally tried this sail repair tape but it comes highly recommended by some friends of mine that I trust their opinion and that is why it is featured in this article.

T-Rex Clear Repair Tape

This tape has earned by far the best reviews. This is due to its versatility and variety of characteristics. Some of them: weather-resistant, all-purpose repairs, adhesive sticks, easy application, and much more. They even claim that it sticks to wet surfaces. However, I still wouldn’t recommend taping your sails together when wet; allow them to dry after cleaning them for best results. It is also pretty cheap so make sure to check it out .

3M All-Weather Duct Tape

As we understand by its name, it’s an all-weather tape suitable for long-lasting repairs on your sails for patching or reinforcing them. What I like the most about this tape is the brand. Call me a marketing victim if you must but I had very good experiences with 3M products and I swear by a lot of their products like their coatings . What I do not like about this tape is the color. It comes in this standard duct tape gray that will look sloppy on your sails. Link to Amazon .

Best Sail Repair Tape – Best Conclusion

Always prefer to choose a specialty sail tape that is designed for the exact type of your sailcloth. Furthermore, remember to buy a kit that includes adhesive-backed patches and top-quality repair tapes. You can use these in order to mend holes and tears in the canvas, plastic, nylon, rubber, and other materials. Above all, remember to have your Sails Repair Kit equipped with all necessary tools and materials to anticipate any possible damage that might appear while at sea. Finally, prefer weather-resistant tapes that ensure durability, are flexible and puncture-resistant in order to ensure long-term performance for your sails.

Peter is the editor of Better Sailing. He has sailed for countless hours and has maintained his own boats and sailboats for years. After years of trial and error, he decided to start this website to share the knowledge.

Related Posts

The Ultimate Guide to Choosing the Best Fishing Line for Trolling

Lagoon Catamaran Review: Are Lagoon Catamarans Good?

Best Inboard Boat Engine Brands

Are O’Day Sailboats Good? A Closer Look at a Classic Brand

- Buyer's Guide

- Destinations

- Maintenance

- Sailing Info

Hit enter to search or ESC to close.

- Create account

- Cut Lengths

- Rope Usage Guide

- Accessories

- Colligo Products

- Deck Hardware

- Snatch Blocks & Loops

- Tiller Extensions

- Winch Handles

- Whisker & Spinnaker Poles

- Rates & Policies

FREE U.S. SHIPPING on orders over $200!

- Snatch Blocks & Loops

- Whisker & Spinnaker Poles

Sound Rigging Tip #413: There's a right way to apply rigging tape. No kidding.

February 16, 2017 • Tape

Rigging tape probably has more uses on a sailboat than duct tape, and we think that's saying a lot. From covering sharp objects to holding stuff in place, it's one of the most useful things in the tool bag. Its stretchy, form fitting, easy to use style makes it a crew favorite on just about every boat. Trouble is, eventually it gets baked by the sun, becomes brittle and the adhesive fails. Next thing you know the tape unwinds, and you have what we in the business refer to as a flag: a ribbon of unrolled tape flapping in the breeze and looking sloppy. Some bits are reachable and easily remedied, but some not so much. One thing's for certain. Flags detract from the handsome look of an otherwise ship-shape boat. What's a skipper to do?

The next time you reach for the rig wrap, try these simple steps to make your tape job last for the whole season.

- Start with a clean roll of tape.

- Cut a clean end and apply the tape by stretching it to a nice form fit.

- Finish up by doing one more wrap, but this time pull the tape just enough so it will lay flat. DO NOT stretch it!

- Finally, CUT (do not rip) the tape and push the bitter end down with your thumb. Note: Cutting the tape on a slight angle, instead of at ninety degrees, seems to work best.

- Want to make doubly sure it doesn't come apart? Smear a wee dab of Elastomeric over the end of the tape. That's about as bullet proof as rigging tape gets.

Follow these simple steps when applying your rigging tape, and see if it doesn't get you through a flag free season. Many thanks to Rigger Dave for sharing his expertise and contributing this article.

Happy Sailing!

← Older Post Newer Post →

- [[html title]]

Rigging Tape White 1" x 10' Roll

- Discontinued

- Create New Wish List

Correlated Items

Product details.

- Description

- Specifications

- Shipping Restrictions

- Questions & Answers

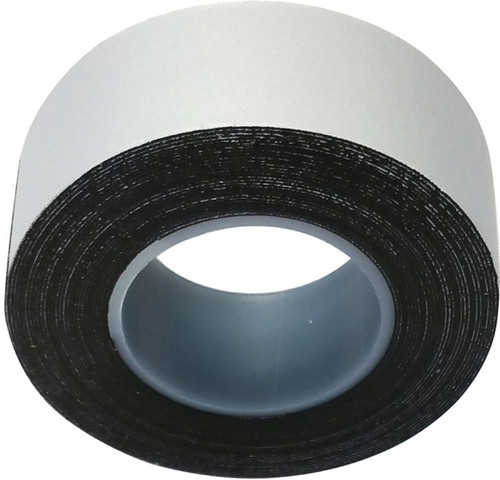

Rigging Tape is a self-bonding tape that protects sails from chafe and sharp protrusions. This tape can be wrapped around turnbuckles, exposed cotter pins or other sharp objects that can harm sails, running rigging or people. This tape can also be used on hot objects for an emergency repair of radiator hoses and the like.

Rigging Tape bonds to itself to make one solid piece and will not ravel. It is also UV resistant and waterproof.

This item is of a size or length that requires additional shipping fees.

Lithium Ion Tools can ONLY be shipped Ground to the 48 contiguous United States.

Flammable items can ONLY be shipped Ground to the 48 contiguous United States.

Lithium-Ion Batteries can ONLY be shipped Ground to the 48 contiguous United States.

Free Ground shipping is not applicable to this item.

Adding this item to your shopping cart will eliminate any air transportation shipping methods.

Adding this item to your shopping cart will eliminate the Post Office as a shipping selection.

This item cannot ship to California due to state restrictions.

Customers Also Purchased

Rigging Tape Black 1" x 10' Roll

Ripstop Repair Tape White 2" x 25'

1/2" White Non-Roll Flat Elastic (1 yd.)

Adhesive Repair Tape Dacron® White 2" x 15'

3M™ Electrical Tape White 3/4" x 66'

Stay in the loop never miss sale announcements, how-to blogs, new product launches, helpful tutorials and more.

- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sails and Rigging

- Maintenance

- Sailing Totem

- Sailor & Galley

- Living Aboard

- Destinations

- Gear & Electronics

- Charter Resources

- Ultimate Boat Giveaway

Sailboat Rigging Tips from a Pro

- By David Bond

- Updated: May 12, 2021

Clive Strickett is a rugged guy, so it takes strong arms to winch him aloft to the masthead. But that’s exactly where you want him: eyeball to halyard sheave, looking for problems. He’s a veteran rigger with a keen eye and a background in ocean racing on the competitive Maxi circuit. On the island of Lanzarote, where I first encountered Strickett, he has a reputation for detail.

We were on the dock at Marina Lanzarote in a fresh breeze of about 20 knots. It was sunny and warm, the sort of weather you’d expect when you’re about 400 nautical miles off the coast of Morocco. These Canary Islands, of which Lanzarote is the farthest north, are a staging area for boats embarking on a trans-Atlantic crossing.

Strickett had just been lowered to the deck of a Bavaria 41 by the boat’s skipper after checking the spreaders, and was now shaking his head. Problems. There are always problems. This time it was mismatched metals. “It’s rare to find a boat that has nothing wrong with it,” he said.

Never mind the Atlantic—the first leg of the trip from the United Kingdom and Europe to the Canaries can be brutal on gear. And that’s before the 3,800-nautical-mile downwind crossing to the Caribbean. It’s wise to have a guy like Strickett check your rig before you leave. “I’ve been doing this for a few years now,” he said. “I might see a problem that the owner missed. They weren’t looking for it, or weren’t looking where they should have been.

“You never know what’s going to happen on boats. Even on new boats,” he continued. “A friend of mine had a new catamaran, a big one, with a carbon-fiber mast. One of the genoa clutches ripped right off the mast. Brand new boat, right from the factory. We had to get the OK from the factory in France to make a repair. We fixed it, and he crossed the Atlantic.”

Minor rig problems compound quickly under pressure. Strong winds funneling through these volcanic islands can mimic trade-wind sailing, but that doesn’t mean that every boat is ready for the crossing. According to Strickett, safety lies in the details, and he points out where to look for potential problems in your rig. Here’s what Strickett is looking for as he inspects a spar, from top to bottom.

Masthead: “Be sure the sheave axles are secure. Sometimes the holes elongate or even crack. And then halyards can get mixed up. One boat that came through here from Tenerife was using the wrong halyard. They were using the spinnaker halyard instead of the genoa halyard. When I went up to look at it, the sheave box was completely gone; the rivets were all loose. The holes had elongated because the halyard was at the wrong angle. They didn’t even realize it. It’s tough to see what’s happening aloft when you’re on deck.”

Working down the mast on a fractional rig, there might be additional sheave boxes fitted for internal halyards. “Make sure all the rivets are tight. Anything fitted with bolts or rivets should be double-checked.”

Spreaders: “Inspect the spreader tips; make sure they’re OK and there’s no corrosion. Whenever you get stainless steel and aluminum together, there’s corrosion. One fleet of charter boats here had put 8 mm stainless bolts into the aluminum spreaders with no protection. Now the spreaders are corroding—the holes get bigger and bigger. But not only that, the spreader was already weakened by putting big holes in it to begin with.”

Shrouds: Broken or damaged wire rigging is the most common problem. “Most cruising boats use 1-by-19 stainless wire. Inside, one strand can let go, then another. When you get up to four broken strands, the wire gets weaker and weaker, and eventually fails. If you’re underway and that happens, then you have a big problem.”

You also don’t want extra weight aloft. “Some people use Dyform, or compacted wire, which uses triangular-shaped strands around a core. If you compare a 10 mm Dyform wire to a 10 mm 1-by-19 wire, the Dyform is stronger. I once changed a 12 mm 1-by-19 wire to a 10 mm Dyform wire. It’s the same strength, but I saved some weight aloft.

“You can’t take anything for granted,” he continued. “There was a boat getting ready to head to the Mediterranean from here, which is a long slog to windward. He was all ready to go. Just as an afterthought, the owner had me look over the rig. Good thing. I found some broken wires in the forestay. The whole mast could have come down. So have a close inspection just to make sure there are no broken wires, and that the terminals don’t have any cracks in them.”

Boom: “Once again, closely inspect the rivets. Loose padeyes on the boom get looser and can easily rip right out. The same goes for the gooseneck fittings. Check every bolt, every rivet for the slightest elongation of the holes or any loose rivets. I can’t emphasize that enough. The padeye is usually secured to the boom with 5 mm Monel rivets, but those can pull loose after a sharp pull like a jibe. They can get yanked right out of the boom. Then what? As insurance, I usually remove the 5 mm rivets and replace them with 6.3 mm rivets, which are the largest you can use. If you’ve had a big jibe and the boom hits a V1 (lower shroud), it might break or bend the boom. We fix booms at our engineering shop. They’ll straighten it, put a patch on, weld it and then paint it. That makes it strong enough. New booms delivered to Lanzarote come from France, and the delivery fee alone can cost up to $3,500.”

Read More: Check your Boat’s Rig

Turnbuckles: “Some people don’t like to tape turnbuckles; they like to see what’s going on with them. Fair enough. I wouldn’t tape it all the way closed though. Just a little tape around the split pins so that they don’t grab a sail or your ankle. On one boat that I inspected, the guy had taped up the whole thing. When we untaped it, it was all manky, which means pretty disgusting. The dirt will always get in somehow. If it’s all taped up like that, you can’t oil or lubricate it. I tell people: Now and then, service your turnbuckles. Take some turns off the turnbuckle. Make sure it’s clean and then put a little Teflon gel on it, or some MolyKote grease. Then tighten it back up.

“When you haven’t done it for some years,” he added, “they seize up and you can’t undo them. Especially a small turnbuckle. They’re chrome-plated over bronze, and when you put a big spanner in there and turn it, it’ll snap. And what you don’t want is for a wire to snap when it’s under load. It’s just preventive maintenance. Do it every six months. It takes only a couple of hours.”

Headsail Furlers: “On some ProFurl furlers, there are four black bolts that go into the furler: two that hold the cage on and two that hold the plate. On the older ones, the bolts are made of titanium, and they seize into the aluminum. I don’t know how many I have had to drill out. But you have to drill them out properly. If it’s a 6 mm bolt, first you drill straight down the middle of the hole with a 3 mm drill, then with a 4 mm, then a 5 mm, then a 5.5 mm. Hopefully it will come out with the heat and friction. ‘Easy-out’ [screw extractors] don’t work. These things are seized together. Even heat doesn’t work.”

Chain Plates: “I inspected one boat with the chain plates so loose, they were actually moving. You could see where they had scratched the paint around the hull. Down below, look carefully at the chain plates. Make sure there’s no cracking in the hull, no movement on the bolts. You can see where a bolt has bent a little, or if it’s been pulled up or down. You’ll see little scratch marks on the hull or the bulkhead.”

Mast Step: “There’s a fine balance between the shrouds being too tight and too loose. There was a good-size catamaran that left here and got into some rough seas, rolling around. The shrouds were too loose, and on one roll, the mast jumped right out of its mast step. It was just for a moment, but in that moment, the mast went overboard.”

With the inspection on the Bavaria completed, as we walked up the gangway toward the marina office, I had one last question: “If something breaks underway, can a rigger or a boatyard be held responsible?”

Strickett answered, “Sometimes. We have a basic form that says something like: ‘Rig checked. All found to be in good condition at the time of inspection.’ And I sign it. So as far as I’m concerned, everything was OK when I signed it. But if along the way, say it blows up to 40 knots and the crew still has their spinnaker up and the mast comes down, well, they might try to come back to us. So in my opinion, it boils down to this: If you’re not up to sailing the boat, then you shouldn’t be there. You just never know what’s going to happen.”

David Bond, a regular contributor to CW, is a writer, teacher and cruising sailor currently based in Germany.

- More: How To , print 2021 april , projects , rig , rigging

- More How To

Grease the Wheels of Your Boat: A Guide to Proper Lubrication

A Bowsprit Reborn: A DIY Renovation Story

Rigging Redo: Our Switch to Synthetic

Top Tools for Sailboat Cruising: Must-Have Gear for 2024

From Paradise to Medical Emergency: A Bahamas Nightmare Turns Lesson Learned

Free Medical Advice: The Unwarranted, Unprofessional Edition

Gatekeepers of the Waterway

- Digital Edition

- Customer Service

- Privacy Policy

- Terms of Use

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

Newbie question- rigging tape

- Thread starter Indysailor

- Start date Apr 30, 2010

- Forums for All Owners

- Ask All Sailors

I need to cover a few pins on my rigging. I haven't used rigging tape before, does it just self adhere? It reminds me of teflon tape used in plumbing. Advice on how to apply it would be greatly appreciated!

Bad Obsession

It depends on what kind of tape you bought. The stuff that I use has a plastic strip that you pull off of the bottom and it self adheres. It looks kind of thick but it stretches a little and you should stretch it some when applying it.

I'd point out that taping your rigging is generally a bad idea...especially if you're on salt water... which I don't believe the OP is. Taping the rigging creates ideal conditions for crevice corrosion of the stainless steel. If you've got bronze rigging, go for it... if you've got stainless steel rigging, you might want to re-think it.

Indysailor said: I need to cover a few pins on my rigging. Click to expand

IIRC, the recommendation for cotter pins is to cut them to 1.5x clevis pin diameter and open the ends to 20˚ as suggested by Rod Stephens. See here . IIRC, he used to carry a small wedge around to check rigging pins.

sailingdog said: Iopen the ends to 20˚ as suggested by Rod Stephens. Click to expand

Thanks! I appreciate the help, folks. This boat is in freshwater, but I have already pulled a cover off one of the shrouds specifically because it wasn't really doing anything as the previous owner had it on an inside one, and I noticed mildew and stuff on the cable. Cleaned it off and it is all right, but I can see why one wouldn't to cover those up if not absolutely needed. The turnbuckles at the chainplates are covered by tubes, and the only places I want to use rigging tape is where pins on the lifelines will catch a sail or a kid's tender thigh. Another place is up on the spreader boots- I just replaced them and the old ones were held on with nylon ties. A friend suggested rigging tape instead. I was just a little perplexed by it, but after wrapping it around my finger, the secret is revealed...the role my friend gave me had a lot of dust on it, which made it more difficult to adhere.

Plenty of good advise here. I am a fresh water sailor. When I do use rigging tape it is always white electrical tape.

Pro's/Con's: Recyle Cotter Pins or Not? This has been a good thread. At three years with my first boat, I'm still sort of a newbie. But I did come to the conclusion a ways back that wrapping the turnbuckles over the cotter pins with rigging (or white electrical) tape didn't seem to add much as long as the sharp ends of the cotter pins were bent so that nothing could be snagged on them. And if I decided that my rig tuning was off, removing the tape was just another step before I could try again. My solution was to use long cotter pins and bend the ends enough in a loop fashion so that they were pointed back at the turnbuckle. I always had wondered though whether having the ends short so that they were within the confines of the turnbuckle and then just opening the cotter pin ends only enough so that they wouldn't slip out was sufficient. The info on this thread (20 degrees) confirms that's ok. That will be my future procedure. Here's a question for debate: I've done cotter pins for all sorts of things since my teenage years; mainly motorcycles and cars. All literature I've read says always use a new pin; never recycle. But heck, provided the used pin doesn't look like its been bent too many times, its just easier and cheaper to put the one you just took out back in. I've never had a failure. Now, if I use only a only the 20 degree bend as referenced in this thread, the cotter pin metal I think wouldn't be stressed hardly at all when it is straightened to be removed from the hole ... and then reinserted. What's your take?

I love rigging tape! Been using it for years on turnbuckles, it is not making it air tight so I'm not worried about oxygen starvation. I like the Navtec brand. I hate tearing things including my skin on cotter pins. I like to go back and forth a few times right over the sharp end then go around a few times. It saves on tape and builds up thickness where you need it. This being said, tape can do some damage over long periods of time. I had a removeable solent stay. There was tape wrapped around it for a length of six inches when I bought the boat on a section that was placed around a curved retaining device. When I set the stay last season, the wire parted in the middle of the tape. I spoke with a rigger, likely it was starved of oxygen and corroded there.

Electrical tape? Does it hold up well? I figured it would deteriorate pretty quickly out in the sun.

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

Oops, it looks like you don’t have anything in your cart. Add some items and try again.

Marine and Rigging Tape

Categories clear all.

- Repair Tape (3)

- Hatch Tape (2)

- $10 to $20 (2)

- $20 to $40 (3)

- rating 5 out of 5 stars (1)

- rating 4 out of 5 stars (1)

- rating 3 out of 5 stars (1)

Rigging Tape and Sail Tape

Rigging tape is similar to electrical tape in that it is a vinyl coated tape with similar adhesive properties. However, it is imperveous to weather and abrasion, and when applying it, rig tape tears much cleaner than electrical tape.

Similar to rig tape in its vinyl protection, chafing tape is designed to protect dock lines, mooring lines, rigging, etc. Developed to withstand salt water. It is 12 mils thick, yet soft and pliable, and will not crack.

Hatch Cover tape is extra thick foam tape that was specifically developed to seal out weather and ocean elements on the rim of hatch covers. It is pressure sensitive.

Need help or have questions? The FAQs in our Help Center cover most account, order, or product-related topics. Click to call or chat with our Total Support Team.

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Ericson 41 Used Boat Review

Mason 33 Used Boat Review

Beneteau 311, Catalina 310 and Hunter 326 Used Boat Comparison

Maine Cat 41 Used Boat Review

Tips From A First “Sail” on the ICW

Tillerpilot Tips and Safety Cautions

Best Crimpers and Strippers for Fixing Marine Electrical Connectors

Thinking Through a Solar Power Installation

Getting the Most Out of Older Sails

How (Not) to Tie Your Boat to a Dock

Stopping Mainsheet Twist

Working with High-Tech Ropes

Fuel Lift Pump: Easy DIY Diesel Fuel System Diagnostic and Repair

Ensuring Safe Shorepower

Sinking? Check Your Stuffing Box

The Rain Catcher’s Guide

Boat Repairs for the Technically Illiterate

Boat Maintenance for the Technically Illiterate: Part 1

Whats the Best Way to Restore Clear Plastic Windows?

Mastering Precision Drilling: How to Use Drill Guides

Giving Bugs the Big Goodbye

Galley Gadgets for the Cruising Sailor

Those Extras you Don’t Need But Love to Have

UV Clothing: Is It Worth the Hype?

Preparing Yourself for Solo Sailing

How to Select Crew for a Passage or Delivery

Preparing A Boat to Sail Solo

On Watch: This 60-Year-Old Hinckley Pilot 35 is Also a Working…

On Watch: America’s Cup

On Watch: All Eyes on Europe Sail Racing

Dear Readers

Chafe Protection for Dock Lines

- Boat Maintenance

Tommy Tape is Tops

Used for mast boots, turnbuckles, hose leaks and wrapping electrical wire, self-amalgamating tape is a chemical marvel..

It’s called elastomeric self-bonding or self-amalgamating tape.

Elastomeric means that it resembles rubber.

Self-bonding means that it sticks to itself, but it’s an incomplete description. It’s not really very sticky to the touch.

Amalgamating—meaning that it merges into a single body—is the best term to describe a tape that morphs into a solid glob.

The stuff is plastic. It’s activated by stretching. The stretching releases a chemical plasticizer, which permeates the built-up layers of tape and converts it to a solid. It likes to be stretched a lot, to burst all of the tiny bubbles of chemical.

It works best if not allowed to sit around unused for months because the gas tends to migrate out, leaving you with a pretty useless roll of something-or-other.

How easy are these tapes to apply, how well do they work and how long do they last?

What We Tested First we rounded up the usual suspects. Three of the seven are from Mariner’s Choice.

Mariner’s Choice Mast Boot is a 4″-wide roll 40″ long (unstretched) that would do to wrap one mast base. Because the tape is wide and difficult to grasp and stretch, it would be best to have a helper to apply it; try it alone and that basic truth will immediately emerge. It’s a nice flat white color.

The other six samples are 1″ wide, easy enough to apply, although stretching and getting the first wrap overlapped (as the instructions suggest) before beginning the spiral, requires a bit of digital dexterity.

Mariner’s Choice Rigging Tape (a 15′ roll), comes white or black. It appears to be the same as the Mast Boot. The package describes it as useful for rope ends and chafe protection.

Mariner’s Choice Safety Wrap is presented as a fix for leaky hoses and an alternative electrical wrap. “Water tight and air tight to 100 psi Plus,” say the instructions. This black tape is separated by a thin white plastic backing, which suggests that it contains more of that chemical plasticizer. The roll has 15′ of unstretched tape. The instructions contain directions for making a temporary repair on a broken fan belt, but it seems a dubious undertaking.

Navtec’s Rig-Rap—”The Ultimate Rigging Tape” heralds the container—is white, and the roll contains a generous 36′. The thin tape, which has a thicker ridge down the centerline to make spiral wrapping easier (it does), is separated by a clear plastic backing that is easy to deal with. On the box is the statement, “Not affected by sun…doesn’t dry up or deteriorate.” We’ll see.

Rubbaweld, from Simpson Lawrence, is inch-wide tape, but the package doesn’t say how much is on the roll. We unrolled it and got 16′, unstretched. Simpson Lawrence says Rubbaweld is waterproof and good for all the usual tasks: electrical, turnbuckles, leaking hoses, mast boots, chafe protection and insulation.

The black Rubbaweld is on a thin, plastic backing, also black, that will try your patience, eyesight, touch and vocabulary. We tried all the tricks we know, including stretching, and a partial slit and a fingernail. Suffice to say: Once you establish a separation, don’t lose it!

Tommy Tape comes in a number of versions: white, black, light, medium and heavy duty, flat, and ridged down the centerline (like Rig-Rap). It has a clear plastic strip that, because it’s wider than the tape, is easy to separate. It comes in rolls all the way from 10′ to 36′ and is seen in hardware and auto parts stores.

Tommy Tape is the only one of our samples that in the larger rolls lists full specifications and properties. These include a temperature range (65°C-260°C/-85°F-500°F), dielectric strength and constant figures, volume resistivity, water absorption and shelf life. On request, Tommy Tape will supply tensile strength figures, duro hardness, tear resistance, ultimate elongation and dissipation factors.

West Marine’s “Self-Bonding Rigging Tape” appears to be the same as Mariner’s Choice. (Mariner’s Choice tape is made in Canada; West Marine’s package says “Made in Canada for West Marine.” West’s tape, available only in white in 15′ rolls, is very heavy, very stretchy and has a transparent backing that is almost as difficult as the Rubbaweld. It costs $8.39—60¢ cheaper than Mariner’s Choice’s rigging tape.

Twisting in the Sun Mariner’s Choice mast boot tape was applied to a short section of 4″ aluminum mast with a slot for a bolt rope. Most of the tape makes direct contact with the anodized aluminum (except for the sail slot).

For the other six samples, generous applications of each tape were placed on a short piece of cylindrical powder-coated aluminum. (It was, as a matter of fact, a bit of tubing sent several years ago by Henry Keene of Edson while Practical Sailor was testing radar mounts. Keene, who is proud of Edson’s powder coating, wrote on it, “Paint test by Hank. Please hit me with your hammer.”)

However, because air, water and dirt can get under tape when used on turnbuckles or electrical wire, a 1/4″ wooden dowel was included under the wrap on Hank’s cylinder.

The mast section and the tubing then were suspended from a piece of small stuff and hung outdoors on the outer end of a tree limb. The shape of the aluminum pieces, dangling from a small cord, encouraged them to revolve almost continually, like a Calder mobile. This gives all parts of each kind of tape even exposure.

The pieces were first exposed in early February, placing the tape at the mercy of some New England cold, snow and sleet as well as rain, sun and temperature changes.

A month later, no change was detectable.

By April, two months into the test period, the tape seemed to be drying out. It felt harder, less sticky and less rubbery.

At the May checkpoint, the three-month mark, the band of white Mariner’s Choice Rigging tape on Hank’s cylinder parted at the point where it passed over the wooden dowel.

To check the impression that all of these tapes were getting harder and less elastic, fresh tape was applied to a piece of stainless steel tubing and compared to the exposed samples. A simple finger nail was all that was needed to indicate clearly that something was happening to the tape.

In June, after getting baked by early summer sun, all of the tapes seemed even dryer and harder—but nothing untoward had happened.

At the five-month mark, the black Simpson-Lawrence Rubbaweld had started to part at the dowel, as shown in the photo. The Rubbaweld felt like it was getting gummy rather than rubber-like.

The others were getting harder.

The ones that seemed to retain the most elasticity were the Navtec Rig-Rap and the Tommy Tape.

Brought in for inspection on Sept. 7, seven months after being exposed to outdoor living, the Simpson-Lawrence Rubbaweld was close to failure—it soon thereafter parted where it passed over the dowel.

In addition, the Navtec Rig-Rap was about half parted, which suggested that it would be next to fail. It did so in a couple of weeks.

Not counting the Mariner’s Choice Mast Boot, which contains a lot of material, that made it three down, three to go.

Brought in at the nine-month mark (early November), these samples can be said to have been exposed for one sailing season in northern climes. In more tropical areas, they probably would, like most materials, have suffered greater deterioration.

The tapes that might, therefore, be called “sure fire” for at least one season are the Mariner’s Choice Safety Wrap, the Tommy Tape and West Marine’s Rigging Tape.

The test was ended at the 12-month mark. The little table embedded on p.19 summarizes what happened. The failures, like those described above, involved the tape parting at the wood dowel or at the top of the slot on the piece of mast. With further exposure, the narrow varieties of tape lose their grip and peel off.

The Bottom Line If these tapes had been used for below-deck repairs, like taping electrical connections or attaching the emergency tiller to a bulkhead or some out-of-the-way piping, the results probably would have been different. Everything lasts longer if kept out of the elements, especially the sun.

Practical Sailor’s outdoor exposure test suggests that the best tape lasts four times as long as the worse. Of the six kinds of narrow tape (with the mast boot version omitted), the two best-in-the-test were Tommy Tape and West Marine Rigging Tape.

The price of these tapes is not much of an issue, except perhaps for the Mariner’s Choice Mast Boot. It comes in two sizes—40″ for about $20 and 100″ for about $30.

The narrow stuff ranges from about 45¢ to 60¢ a foot. That may seem somewhat expensive. But because the tapes stretch five to six times their initial length, real costs become close to negligible. A 15′ roll might run $8 or $9. The cost can be worked down to 25¢ a foot by buying a 100′ roll, but without a lot of projects you’d be hard put to use it up before it loses its unique amalgamating quality.

Tommy Tape carries the lowest price. It’s not a “marine” product; it’s available in hardware stores. It occupies the unique position, not often seen in Practical Sailor’s testing, of being not only tied for the best in the test, but also the Best Buy.

Contact- Mariner’s Choice, 6219 Monita St., Long Beach, CA 90803, 562/598-5861, fax 562/430-8377. Navtec, 351 New Whitfield, Guilford, CT 06437-0388, 203/458-3163, fax 203/458-9291, email info@navtec. Simpson-Lawrence, 6208 28th St. E., Bradenton, FL 342203-4123, fax 941/746-7166. Tommy Tape, Box 555, Palm City, FL 34991, 561/223-1991, fax 561/223-1995.West Marine, 500 Westridge, Watsonville, CA 95077-0507, 800/937-8895. fax 205/581-9447.

Also With This Article Click here to view Exposure Results .

RELATED ARTICLES MORE FROM AUTHOR

Leave a reply cancel reply.

Log in to leave a comment

Latest Videos

What’s the Best Sailboats for Beginners?

Why Does A Sailboat Keel Fall Off?

The Perfect Family Sailboat! Hunter 27-2 – Boat Review

Pettit EZ-Poxy – How to Paint a Boat

Latest sailboat review.

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

BIG DEAL sale now thru Sept 8th! Get storewide savings and save up to 70% in the clearance section. SHOP SALE

- Sailboat Gear

Rubbaweld Rigging Tape

- Create New Wish List

Description

Related products.

Viadana Single Ball Bearing Block 38mm

Viadana Single Ball Bearing Block w/Becket 38mm

Viadana Single Ball Bearing Block 38mm w/Swivel

Viadana Double Ball Bearing Block 38mm

Viadana Single Ball Bearing Block w/Becket w/Swivel 38mm

- Forum Listing

- Marketplace

- Advanced Search

- About The Boat

- Gear & Maintenance

- SailNet is a forum community dedicated to Sailing enthusiasts. Come join the discussion about sailing, modifications, classifieds, troubleshooting, repairs, reviews, maintenance, and more!

Rigging Tape

- Add to quote

Hi All, I'm a new boat owner and have certainly been learning a lot. Can someone tell me what the purpose of rigging tape is? It *seems* to me that it is mostly used for holding in cotter pins. But I get the feeling that some people are using it for more than just that....I feel like I must be missing something. 2nd part of the question: Any thoughts on using that new self adhesive silicone, "rescue tape" stuff instead of what basically looks like white electrical tape? thanks!

stoomy said: Hi All, I'm a new boat owner and have certainly been learning a lot. Can someone tell me what the purpose of rigging tape is? It *seems* to me that it is mostly used for holding in cotter pins. But I get the feeling that some people are using it for more than just that....I feel like I must be missing something. Click to expand...

2nd part of the question: Any thoughts on using that new self adhesive silicone, "rescue tape" stuff instead of what basically looks like white electrical tape? thanks! Click to expand...

Good rigging tape is rubberized. You stretch it when you wrap your fitting, and then it melds itself into a more or less solid mass that will likely need a knife to cut open when you want to pull the rig at the end of the season. Maybe the "rescue tape" is similar to this. Tape not only keeps cotter pins & rings in place, and keeps sails from getting snagged, but can also help to cut down on chafe: spreader tips, for example.

I like the Dupont vinyl plastic tape which is the “rigging” tape at the chandleries. You can get the same stuff for cheaper at your local hardware store or Frye’s Electronics. I also use butyl rubber tape to build up areas (like where the lifelines attach to the pulpit) then tape over with the rigging tape.

My experience with Rescue Tape on topside fittings is that UV damages it quickly and it breaks. Rigger's tape is the way to go.

I use the 3M Scotch 88 electrical tape. I heard that lesser electrical tapes will get sticky or brittle, the 88 stays flexible and the adhesive lasts. Can't confirm that other tape doesn't work.

mitiempo said: ] I have used rigging tape to make a bandaid in the past - a little paper towel and some antibiotic ointment and it will not fall off when soaking wet. Click to expand...

Duct Tape leaves behind a really sticky mess that seems like it could make further turnbuckle adjustment really messy. Rigging tape sticks to itself, but not the turnbuckles, so when you remove it everything is very clean. Rescue tape works similarly, but I don't think it will last as long out in the sun. Rigging tape isn't that expensive, a roll of it will last you a very long time.

Alex W said: Rigging tape isn't that expensive, a roll of it will last you a very long time. Click to expand...

stoomy said: Can someone tell me what the purpose of rigging tape is? Click to expand...

Oh, to answer the original question, here're some things I used tape for. Bear in mind that I race of club J/24s that I have neither the permission nor inclination to make changes to, so I use tape for a lot of things that I'd just fix if it were my boat. * Taping cotter pins/ring-dings to keep them in place and from snagging things * Taping closed pelican hook on lifelines to keep them from opening unexpectedly * Keeping loose snap shackles from opening unexpectedly * Fixing damaged whipping on lines * Taping the downhaul bridle to spin poles (boats don't have a foreguy) * Streamlining exposed bolts, mooring line fairleads, etc that might snag lines/sails * Attaching the topping lift to the side stays * Giving the vang some girth so a blown-out cleat can grab it * etc... Suffice to day, I don't keel okay on a boat unless I have my tape with me. (And I go through like 4 rolls a year.)

I use scar pins, make my own to the sizes I need. No tape. APS - E Scow Accessories

White 3M Super 33 7 mil electrical insulating tape that applies well in broad temperature range. Flame-retardant, hot- and cold-weather resistant; resists UV rays, abrasion, moisture, alkalies, acids and corrosion. cheep everyplace works well

- ?

- 176.1K members

Top Contributors this Month

- Sailboat Care

Incom Rigging Tape

Incom manufacturing group, write a review.

- Create New Wish List

- Description

Manufacturer part #: RE3866

- Related Products

Incom Rigging Tape White

Incom Mast Boot Tape, 4" x 40"

Johnson Marine Riggers Grade Rigging Tape - White

Johnson Marine Riggers Grade Rigging Tape - Black

- Yachting Monthly

- Digital edition

How to tension your yacht’s rig with wire or rod rigging

- August 28, 2024

Ivar Dedekam author of Illustrated Sail & Rig Tuning gives his guide on tensioning a yacht's wire or rod rigging

If you want to trim your rig correctly you should have some idea of the tension in the shrouds and stays, either by rules of thumb or a more exact method, such as this. Here, you measure the stretch of the wire as a percentage and then establish the tension as a percentage of the wire or rod’s breaking load.

You can either measure the stretch of all the wire or a part of it, e.g. 2m. Accuracy will improve with the sample length. Begin with a minimum tension in the wire.

Mark off a 2m length of the shroud on one side of the boat using the shroud terminal for reference. Measure the elastic extension (f) of the measured length as the rigging screws are alternately tightened, little by little. Stop when f = 3mm. (4mm on fractional rigs with aft swept spreaders).

Note that stretch of f = 1mm over a sample of 2m of the wire corresponds to 5% of breaking load independent of the wire diameter. For rod, an f = 1mm stretch over 2m corresponds to 7.5% of breaking load. Use a similar method to establish backstay tension. Remember that a different sample length will have a different stretch for the same load. Also remember that the stretch is always measured from hand tight wire/rod (minimum tension).

Mark up the shroud Mark up 2m of shroud using the terminal for reference…

Rod rigging is made of a straight, single strand. Wire rigging is made of many twisted strands. Normally rod rigging is 20% stronger than wire of the same diameter.

Wire has the advantage of an early warning of fatigue when a strand breaks. Fatigue in rod happens without any warning at all. It can be sudden and sometimes catastrophic.

Tensioning cap shrouds

When you have straightened the mast sideways and adjusted the rake, it is time to look at the cap shrouds. Tighten the cap shrouds to approximately 15% of breaking load. This corresponds to a stretch (f) of 3mm over a length of 200cm. On a fractional rig with aft swept spreaders the cap shrouds should be tensioned to 20% of the breaking load. This corresponds to a stretch of f = 4mm.

Measure the stretch…then measure the elastic extension when the rigging has been tightened.

To avoid excessive forestay sag upwind, the cap shrouds should be relatively highly tensioned. If 20% cap shroud tension is not sufficient to keep sag at an acceptable level, increase the tension to 25% of breaking load. Do not exceed this tension.

Slack rigging will produce shock loads that can cause rig failure and may even bring the mast down. Note that you will not be able to overtighten a wire of 40-50cm length with hand tools. The lower shrouds and intermediate shrouds should be quite loose at this stage.

If the mast has distinct bends you should try to straighten them by sight and hand tensioning.

Many yachtsmen intuitively tension their standing rigging and adjust it later when sailing has begun. This may lead to acceptable results but the methods described above, while taking some time, are more certain and reliable.

Enjoyed reading this?

A subscription to Yachting Monthly magazine costs around 40% less than the cover price, so you can save money compared to buying single issues .

Print and digital editions are available through Magazines Direct – where you can also find the latest deals .

YM is packed with information to help you get the most from your time on the water.

- Take your seamanship to the next level with tips, advice and skills from our experts

- Impartial in-depth reviews of the latest yachts and equipment

- Cruising guides to help you reach those dream destinations

Follow us on Facebook , Twitter and Instagram.

Please verify you are a human

Access to this page has been denied because we believe you are using automation tools to browse the website.

This may happen as a result of the following:

- Javascript is disabled or blocked by an extension (ad blockers for example)

- Your browser does not support cookies

Please make sure that Javascript and cookies are enabled on your browser and that you are not blocking them from loading.

Reference ID: 7ede13d4-6727-11ef-a328-8a82bb6e100a

Powered by PerimeterX , Inc.

IMAGES

VIDEO

COMMENTS

Self-bonding tape conforms to irregular shapes and holds fast without sticky adhesives. Durable and waterproof, with UV inhibitors. 1"W x 10'L per roll—stretches to two times its original length. Protective plastic liner. Key Features. Protects sails and sheets from chafe damage. Self bonding; 1"W x 10'L. Black or White. Protective plastic liner.

Shop the best selection of Rigging Tape from West Marine. Visit for products, prices, deals and more! ... 3" X 5' Sail Tape Ripstop Nylon Tape, White 1" X 25' Heavy Duty Anti-Chafing Tape 2" X 25' Ripstop Nylon Tape, Assorted Colors Plastic Rigging Tape ...

Johnson Marine. This Rubbaweld® professional grade self-amalgamating rigging tape works well at covering up cotter pins or any sharp objects that can damage sails, lines, or people. When properly applied, this tape bonds to itself to form a single integral structure. The tape is adhesive-free, so there is no stickiness to deal with when applying.

1-16 of 31 results for "sailboat rigging tape" Results. Check each product page for other buying options. Price and other details may vary based on product size and color. Incom 834-re3947 Rigging Tape Self-Adhesive 19 mmx32,9 m, White. 4.6 out of 5 stars. 185. 200+ bought in past month.

Rig Wrap: Coil the clear tape around rigging in places where the sails come in touch. Also, it provides a friction-free surface to facilitate the passage of sails when tacking and gybing. ... Kevlar Sail Repair Tape/Patch: A high performance and emergency Kevlar/Mylar laminate tape for strong repairs to racing sails. The Kevlar patch contains 2 ...

Shop sailboat rigging hardware, including stainless steel rigging hardware, marine rigging supplies, and detailed parts of a sailboat rigging. Shop now! Need Help? ... Rigging Tape - White. SKU: 166163 | Item ID: INC RE3867. $17.14. In Stock. Hayn Marine Hi-Mod Compression Toggles. Available in 17 options. $104.30 - $1,036.99. In Stock.

Rigging tape probably has more uses on a sailboat than duct tape, and we think that's saying a lot. From covering sharp objects to holding stuff in place, it's one of the most useful things in the tool bag. Its stretchy, form fitting, easy to use style makes it a crew favorite on just about every boat. Trouble is, even

Product Details. Rigging Tape is a self-bonding tape that protects sails from chafe and sharp protrusions. This tape can be wrapped around turnbuckles, exposed cotter pins or other sharp objects that can harm sails, running rigging or people. This tape can also be used on hot objects for an emergency repair of radiator hoses and the like.

Amazon.com: rigging tape sailboat white. Skip to main content.us. Delivering to Lebanon 66952 Update location All. Select the department you ...

But you have to drill them out properly. If it's a 6 mm bolt, first you drill straight down the middle of the hole with a 3 mm drill, then with a 4 mm, then a 5 mm, then a 5.5 mm. Hopefully it will come out with the heat and friction. 'Easy-out' [screw extractors] don't work. These things are seized together.

The turnbuckles at the chainplates are covered by tubes, and the only places I want to use rigging tape is where pins on the lifelines will catch a sail or a kid's tender thigh. Another place is up on the spreader boots- I just replaced them and the old ones were held on with nylon ties. A friend suggested rigging tape instead.

Rigging tape and chafing tape are vinyl tapes that were developed specifically to protect rigging and lines from the elements of sun, salt and weather. ... Rigging Tape and Sail Tape. Rigging tape is similar to electrical tape in that it is a vinyl coated tape with similar adhesive properties. However, it is imperveous to weather and abrasion ...

Of the six kinds of narrow tape (with the mast boot version omitted), the two best-in-the-test were Tommy Tape and West Marine Rigging Tape. The price of these tapes is not much of an issue, except perhaps for the Mariner's Choice Mast Boot. It comes in two sizes—40″ for about $20 and 100″ for about $30.

Sailboat Gear; Rubbaweld Rigging Tape; Rubbaweld Rigging Tape. SKU: SJ-50-115 UPC: MPN: $16.00. Current Stock: Quantity: Decrease Quantity of ... Johnson's Rubbaweld Self-Amalgamting Rigging Tape welds itself into a solid waterproof skin over fittings and hardware. It is also a great way to protect electrical fittings from corrosion, and to ...

Low-Friction Rigging Tape. Model # 6865653 Mfg # 53926. $24.94 $59.99. Additional 50% off savings is reflected in final price above. -. +. Add to Cart. Buy in monthly payments with Affirm on orders over $50. Learn more.

paulk. 5672 posts · Joined 2000. #3 · Mar 24, 2014. Good rigging tape is rubberized. You stretch it when you wrap your fitting, and then it melds itself into a more or less solid mass that will likely need a knife to cut open when you want to pull the rig at the end of the season. Maybe the "rescue tape" is similar to this.

Buy Incom Rigging Tape, RE3866, sailing gear, sailboat parts, sails and running rigging at Vela Sailing Supply. Technical support, customer service and product information. Vela and sailing supplies. ... Life Safe Self Bonding Rigging Tape. Model. RE3866. Color. Black. Size. 1" W x 15' L.

Shop the best selection of WEST MARINE Rigging Tape from West Marine. Visit for products, prices, deals and more! ... Sail Rigging. Rigging Tools. Vangs; Architectural Rigging; Sailboat Blocks; Sailing Shackles, Snaps & Fittings; Sailing Winches; Sail Tracks, Travelers & Leads; Sailing Cleats;

Rod rigging is made of a straight, single strand. Wire rigging is made of many twisted strands. Normally rod rigging is 20% stronger than wire of the same diameter. Wire has the advantage of an early warning of fatigue when a strand breaks. Fatigue in rod happens without any warning at all. It can be sudden and sometimes catastrophic.

West Marine's selection of boat rigging hardware encompasses all the most respected brands, including FSE Robline, Loos, New England Ropes, Ronstan, Samson Rope, Alexander Roberts, Alps Wire Rope, C. Sherman Johnson, Schaefer, Suncor and Edson Marine to name a few. Of course, for hard or complicated jobs, experienced professionals at West ...

Shop HOLT Sail Repair Tape at West Marine. Visit for prices, reviews, deals and more! ... rigging tape HOLT. Sail Repair Tape Clearance HOLT. Sail Repair Tape 4.4 out of 5 Customer Rating Model # 5359492 Mfg # P027501000W. Clearance $5.44 Price reduced from ...

Regardless of whether you own a traditional sailboat, offshore cruiser, club racer, high-tech dinghy or cutting edge racer, our master riggers are ready to help. And with easy ordering, guaranteed quality and fast service, it's no wonder that sailors everywhere increasingly turn to us for the rigging they need! ... Rigging Tape Sail Rigging ...