JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

- My Wish List

- Compare Products

- Create an Account

- Dealer Locator

2022 SAILBOAT HARDWARE CATALOGUE

Mainsheet Systems

This system is based on the typical Aussie Skiff Mainsheet System. It is commonly used on dinghies, skiffs and small sports boats, with a 3:1 end-boom purchase system. The blocks shown in the image are RF48109 x 3 and RF62175 x 1. Sailors of smaller boats may wish to substitute the RF48109’s for RF35101 ’s. The RF62175 can be substituted for RF62174 if the cleat is not desired. Smaller boats can use RF56101 . The bridle can be constructed from Dyneema® such as Robline Ocean 3000 XG. An adjustable splice on each end (where it connects to the hull) is desirable so that the bridle height can be adjusted so that at max Vang and Cunningham the bridle is just block to block; this ensures the boom is on the centreline for height upwind. If possible, use a tapered mainsheet, which should be set up so that the “thin part” can’t ever go into the ratchet block when fully sheeted.

MWL = 325kg (715 lb) Max Line Size = 9mm (5/16")

* RF6 max line 8mm (5/16")

VARIATIONS Die-hard racers can replace the forward RF48109 and the RF48109 on the traveller with RF35109HL to reduce windage, however a tapered sheet would need to be used. Purchase can be increased as required by changing blocks to doubles etc if needed.

MWL = 500kg (1100 lb) Max Line Size = 10mm (3/8")

VARIATIONS Replace RF72700 with RF72900 for yachts up to 12m (40ft).

This incredibly powerful system is ideal for high performance yet relatively light/small racing boats. The yellow line (3:1 coarse tune for quick sheeting) in the diagram is tapered so that the thick part can’t go into the ratchet sheave when fully sheeted. The purple line (21:1 fine tune for accurate trimming) could be tapered if you were a real enthusiast, however being such a small diameter, the gains would be minimal. You would likely set the RF35302 as far forward in the boom as possible to maximise the travel of the fine tune. High load exit blocks, RF45711HL or RF35711HL , are used to lead the lines inside the boom, where the 7:1 fine tune is kept tucked away for minimal windage when powering upwind. If required a ratchet block, RF62175 , could be used on the boom, however this is likely overkill in most applications since the load on the fine tune is relatively low.

MWL = 250kg (550lb) Max Line Size = 10mm (3/8")

Official Sponsors of the Australian Sailing Team

The ‘A’ Class Catamaran – Its place at the top table.

At 18ft long with a total allowed rig area of 150ft2, but weighing in at a mere 75kg, the ‘A’ Class is very much a Formula One car in catamaran form and in the last few years, developments have seen this class take off more than ever before, quite literally.

Anyone with an interest in the hi-tech aspects of sailing will probably know something of the ‘A’ Cat. They are spread worldwide with large fleets in Australia, USA/Canada, throughout Europe and there is even a growing fleet emerging in Argentina. They have had some 55+ years of open design resulting in them now being amongst the most highly developed small sailing boat classes on the planet.

Some History.

Originating from a desire in the late 1950’s by the IYRU (Later renamed ISAF and now World Sailing), to encourage racing and design development of catamarans. They proposed four classes with simple size criteria based on length, beam and sail area, and crucially, with minimal design rules. The A-Class logo was chosen by the IYRU when their committee decided in 1956 to classify the catamarans into those 4 categories. A, B, C and D as construction classes. To symbolize the two hulls the letter "A" had a double underlign, same as the B's, the C's and the D's. From the beginning the A-Cats had the double underligned letter "A" on the sails and it was used on the letter heads. (Examples were the A-Lion, Australis, Unicorn, Quest A, Catalina, Rhapsody a.s.o.). The ‘A’ class is by far the largest remnant of the four classes. The ‘B’ class was a 20ft twin hander with 235ft2 of sail and developed into the Tornado and a few offshoots such as the F18. The ‘C’ class was another twin, but at 25ft with a 300ft2 rig, has become a super sophisticated monster and the pinnacle of small cat design that races for the Little America’s Cup. The ‘D’ Class was 32ft and a sail of 500ft2 with three crew, but rapidly dwindled away.

Various designs for the ‘A’ bubbled away until the IYRU held trials to seek out the best designs in the ‘A’ and ‘B’ classes and to award them international status. At the Catamaran Club on the Isle of Sheppey in 1967, the Tornado won the ‘B’ class, and in the ‘A’ class category the British Unicorn competed, along with with several other boats, against Graham Johnston’s Australian Australis design. At that time the spec was simply to be a single-handed cat with sliding seat or trapeze restricted only by length, beam and sail area. The Australis design won and gained international class status. However, the Unicorn design still gained popularity in the UK and Europe. It eventually became a strict one-design class with rules on hulls, weight and mast diameter, which accounts for the vastly different sail shapes now seen on the two boat designs. Today the Unicorn still measures and is still accepted as an ‘A’ Class cat.

So, the free reign given within the ‘A’s development class spec allowed several other designs to arrive, each an attempt to improve on the other. All modern designs can trace their evolution back to these early boats in one way or another. Many home built designs turned up, and home building of ‘A’ Cats continues today, particularly in the USA, where home building tends to be more popular.

As building and materials technology improved, the stitch and glue plywood built and the glass fibre built boats, in order to save weight and get down to the absolute minimum, needed to be made with the strength only in certain high load areas – shroud plates, beam mounts, foil cases etc., This resulted in the class getting a bit of a reputation for being fast but rather delicate. Gradually these materials gave way to the carbon foam and carbon nomex sandwich construction.

Fast Hull Shapes

The Australis hulls were pointed at both ends similar to a canoe, in an attempt to produce a drag-reducing hull. The designs were often determined by the materials available and nowadays space age construction techniques are possibly one reason that the modern boat is now becoming increasingly popular, as it is producing immensely stiff and strong yet light boats, capable of withstanding hard racing for several years.

Currently, the modern ‘A’ cat bears a striking resemblance to its rather higher profile cousin, the AC45 . The distinctive Dreadnought shaped bows of the ‘wave-piercing’ hull design reduces the pitching moment when in waves. The hull is essentially upside down when compared to many boat hulls. The widest part is towards the bottom with the result that the hull won’t sink as far before the buoyancy starts to push it up again so floats higher. They also tend to have the beams bonded in making it a very stiff one-piece unit. Hull sections and profiles continue to change. The requirements of a boat designed to foil mean that the underwater hull shapes are starting to be optimized for lighter wind sailing, as the hull should be out of the water when it is going fast in a higher wind.

On the latest 2016 boats, aerodynamic drag is now recognized as increasingly more important as the airflow over the boat, with the added apparent wind, can sometimes be as high as 30 or 40 knots. Beams are now aerodynamically streamlined, smoothing the airflow over the drumskin tight trampoline. Double skin trampolines are also a new design feature. Previously the underside of the tramp was a mass of ropes, chords and bungees. Now these are sandwiched between two airtight skins. On one new design, the Holland Composites DNA, even the tiller bar is now streamlined to match the rear beams curved profile!

There are several elements key to the ‘A’ cats speed and success. Over the last 15 years much work has been done on the design of foils (rudders and daggerboards). Initially the foils were all straight as the technology to make them anything else, without risking failure, was simply not available. However, they could be put in at an angle and canted towards the centerline. This seemed to give a little lift to the boat, thus making it faster by reducing the drag of the hull when the boat was heeled and flying a hull. They were also made slimmer and longer, and this higher aspect ratio vastly improved the drag effects over a broader chord foil. Then in 2005, Dutch composites expert and sailor, Pieterjan Dwarshuis, raced in the Worlds with a C shaped foil. This supplied much more lift and helped in getting the windward hull flying when going downwind – doing ‘the Wild Thing’ as it is known in cat circles. And, as the leeward foil curved under the boat more, it produced much more lift as the angle of attack (Rake) could be adjusted also. Result – particularly when combined with small winglets on the rudders was that the boats went faster. Within a couple of years these foils became more commonplace and by 2008 German sailor, Bob Baier, had won the European championships using a set.

However, some feared that complex hydrofoils could possibly be fitted to the boat, rendering it fast but impractical and expensive. So in 2009 a rule was brought in with the intention of preventing this hydrofoiling from happening. The now famous ‘A’ class ‘Rule 8’ stating that all foils must be inserted from the top of the hull, and that there must be a minimum distance between the tips of the bottom of the boards of 75cm from the centreline. That seemed to do the trick and for a few years things went along nicely. But the foil building technology steadily improved and a consistent way was found of producing extremely strong shaped daggerboards from carbon composites. In 2013 the foils had developed from a C shape into a J shape and as a result of redesigned rudder winglets, positioning them at the bottom of the blade, the boats started leaping about like salmon. So the next logical move for this development class boat was obvious and was to make it fly. The boat has about the same power to weight ratio as a foiling Moth so it was assumed that it should be able to fly, but for one crucial potential problem – Rule 8. This meant that conventional L shaped boards, similar to the AC boats foils, are not class legal. But thinking around corners is what designers and sailors like to do and before long, designs for foils emerged that complied with the top insertion, limited span restrictions and provided enough lift to get the boat clear out of the water. A movable rake system allowed the angle of attack of the boards to be varied combined with fore and aft movements of the crew weight. The real turning point came in 2014 before the Worlds in New Zealand.

Many of the America’s Cup crews are also ‘A’ cat sailors. In fact the most successful ‘A’ Class World Champion is the ETNZ skipper Glenn Ashby.

The ETNZ America’s Cup team took delivery of half a dozen ‘A’ cats and set about with gusto seeing how far they could be pushed. Improved, redesigned and strengthened boards and rudders started flying around the world on express carriers as they broke and re-broke the foils in an attempt to push the boat to it’s limits. It worked and the boats started to fly, albeit in the hands of these sailing superstars, but techniques were discovered for getting the boats foiling for longer each time. As a result of this, Glenn Ashby won yet another world title. This paved the way for the current developments.

Optimized designs, where daggerboard positions and beams are moved slightly, and newer, more stable foil sections that have lower drag are now arriving, with a Z and J/Z shaped board proving more stable when combined with T or L shaped rudder tips. However, the holy grail of upwind foiling is still being worked on. And this is all still done within the restrictions of Rule 8. The top insert only rule has prevented earlier, more stable, and probably easier foiling to happen if an L shaped main foil were to be fitted. However, the very fact that it is less stable probably results in a faster boat and the need to raise windward foil, as would be the case of the higher drag L foil, is unnecessary and something a single-handed sailor’s workload can do without.

Fast Rigs .

The ‘A’ class rules allow you to do anything as long as the total area, including the mast, does not exceed 150ft2. This area has traditionally seen the greatest developments in the past. Shape is entirely up to the sail maker based on mast shape and flexibility. The original masts were flexible tapered affairs as still seen on the Unicorn today. But in the early 1980s the ‘A’ class moved more towards an untapered wing type mast which was able to be rotated, somewhat like the leading edge slat on an aircraft wing, and thus create the sail shape more efficiently and to adjust it to cope with the windspeed changes created by the apparent wind. Techniques developed and composite masts began to appear in Europe about 25 years ago. The sails design paralleled the mast designs.

Initially they were fully battened but conventionally tapered towards the head. Then, in the mid 1980s the ‘Fat Head’ sail appeared on the ‘A’ cat for the first time. This lower drag high-aspect ratio rig, much like a glider wing, allowed and helped the boat to fly a hull much earlier downwind with the resultant reduction in drag. Upwind, powerful 12:1 downhaul and 9:1 mainsheet systems could flatten the sail and when the carbon mast arrived, this was even more efficiently achieved. As the sail area is the determining factor, not the shape, variations were tried at various times. Really ‘Fathead’ sails, with the heads at over 1000mm were the thing for a while. These required the leech to be cut away in a concave manner to conform the area rule, but now the more popular ‘800’ head offers a good compromise of power and heeling moment. Rigid wing type rigs were also seen occasionally. Back in 1978, at the European championships, a wing sail proved unbeatable in light winds. More recently designers, such as the US mast maker and ‘A’ cat ace Ben Hall, have experimented with a wing sails. But, their practical handling off the water still proving troublesome.

The most current sail development is the ‘Decksweeper’ sail. This is a sail that uses the trampoline as the end plate, making it more efficient, similar to winglets seen on airliners. The sail has its centre of effort lower down, and thus reduces the heeling force created by the fatter head sail and is ideal for a foiling design. The byproduct of this is that going upwind, where any heeling force, above just flying a hull, is not wanted with either foil design, is that it feels like you have another gear. Now much more of the power is pushing you forward. And this is usually sufficient to compensate for the higher drag created by the more complex shaped foils with their higher surface area. So, faster uphill, faster downhill, what’s not to like? However, the downside is that when it’s not foiling conditions, the decksweeper is less powerful and thus the C board, or ‘Classic’ boat is still king.

The decksweeper was first tried on the ‘A’ cat in 1987 in Australia but proved to be unbeneficial compared with more conventional designs. It was tried again a few years ago, by former World Champion Mischa Heemskerk, who was interested in exploring it again on a more modern boat design. The trials were inconclusive and the project was shelved for a while. Then 2015, in the search for more power but with less sideways pressure, as required by a foiling boat’s need to be sailed flatter, he reappeared with one at the 2015 Dutch Nationals and wiped the floor with everyone, including Glenn Ashby, who was there getting ready for the Worlds a few weeks later. But you can’t keep that friendly little Aussie down for long. When he arrived at the Worlds, he’d simply chopped one of his older sails down along the leech, and sewn an extra bit onto the bottom to reach the tramp. This was enough to get him back on track speedwise, and in a variety of conditions, he managed to beat Heemskerk by an increasing margin each race to retail his World title.

Much design work was done over the winter of 2015/16 and two of the major manufacturers both produced more optimized designs. The Polish Exploder came out with their Ad3, with a design input from the Spanish based D3 Applied Technologies design team. The other was the Holland Composites DNA F1 design. A radical looking boat with advanced aerodynamic features and a fully carbon fabric stiff trampoline. Both designs have proved to be game changers and with little to choose from as regards performance. Misch Heemskerk won the 2016 Worlds on the F1 with Darren Bundock 2nd on the Ad3. Both designs foil earlier and are more stable when doing so making them easier to control. It would appear that the design curve is starting to flatten out again now as regards hull and foil design with these two boats setting the standard of performance.

The ‘A’ Class Future

The two foil types are causing a little debate within the class though. Although all the boats measure as ‘A’ Class cats equally, the foiling/floating thing appears to irk some in a few national class associations. Some want separate races for foilers, claiming that is not fair now to race both on the same course. A movement to start a ‘Classic’ class of non-foiling boats has been suggested. But, most associations simply prefer to split out the results and run a parallel results system. And, at those lighter wind events, or in areas like Southern Germany, you don’t hear many complaints.

New foiling boats arrive and older second hand straight or C board boats find ready new homes with some being converted to a foiling configuration with new foil cases and rudders, whilst others are sold to the encouraging number of new sailors entering the class. This is often the best place to start, as it’s not actually a hard boat to sail initially. (The class has a minimum of 5kts and max. limit of 22 kts of wind for racing) Beautifully fast and responsive yet without many of the unpleasant characteristics that some other cats will catch you out on, e.g. the long bows tend to reduce pitchpoling. The added benefit of being 75kg makes it really easy boat to handle ashore; a true single hander, the only thing where you might need someone else’s help for 2 minutes is with stepping the mast.

The next jump looks like it will be in rig design. It’s open design rules means that it will continue to see innovation and development within its rules as yet more ways are found to make them go even faster. Their ability to be altered, modified and improved will also continue to see the ‘A’ cat being used as a test vehicle for design ideas on larger boats. Who knows what is around the corner designwise, but the ‘A’ cat should be able to meet the challenge.

The British

'a' class catamaran, association.

The official site for the British 'A' Class Catamaran Association. Designed to inform new and existing 'A' Cat sailors about UK 'A' Class trends.

Technical Section

In this section, you will find explanations, setup advice and some videos about various technical aspects of the 'A' Class Catamaran, all provided by expert sailors and designers to help you to get the best from your boat. It covers both Classic and Foiling designs.

Mainsheet systems.

Australian International A Division Catamaran Association

All you need to know about sailing A Class Catamarans in Australia

A Class Cascading Mainsheet System

Ref attached, with thanks to Grant Pellew, and Harken, our 2016 Nationals sponsor.

A CLASS—2015 CASCADE MAINSHEET SYSTEM

Related Posts

VALE Brian Jennings

Memories of the a-cat and the class: ian “storm” johnson, nor: 2024 lake boga easter regatta.

Fast Dispatch, Fast Delivery and a 5 Star Rated Service

- MENS SAILING CLOTHING

- DYNEEMA TRAPEZE LINES AND ROPES

- SINGLE SHEAVE BLOCKS

- Gelcoat Fillers

- Dry Lubricants

- Adhesive Glues

- Hooks & Clips

- Catamaran Launching Trollies

- Jockey Wheels

- Hitch Locks

- Lighting Board

- Breakaway Cables

- Clew Straps

- Upper Masts

- Lower Masts

- Rope Thimbles

- Wind Indicators & Burgees

- Parrel Beads

- Whipping Twine

- Sailmakers Palm

- Digital Compasses

- DEVOTI ILCA

- LASER SAIL BOATS & DINGHYS

- BAHIA SAIL BOATS & DINGHYS

- Numbers & Letters

- Dinghy Covers

- Under Covers

- Catamaran Covers

- Single Handed

- Double Handed

- 18 Foot Skiff

- Exocet Moth

- Musto Skiff

- Dart 15/ Sprint 15

- Hurricane 5.9

- Laser Bahia

- Laser Cascais

- Laser Funboat

- Laser Stratos

Your Cart is Empty

- £0.00 Subtotal

Tax included and shipping calculated at checkout

Order before midday Monday to Friday and we will ship your order the same day.

- 01268 222912

- Accessories

- Laser Products

- Sails & Covers

- Rope Lengths

- Parts By Boat

- Boat Care & Cleaning

- Splicing Tools

- Boat Covers

- Dinghy Rope Lengths

- Laser Rope Lengths

- RS Rope Lenghts

- Catamaran Rope Lengths

- Laser Performance

- Topper Sailboats

- Other Boats

- Mens Sailing Clothing

- Womens Sailing Clothing

- Junior Sailing Clothing

- Repair Kits

- Skiff Suits

- Life Jackets

- Trapeze Harnesses

- Buoyancy Aids

- Hiking Pads & Pants

- Hiking / Toe Straps

Zhik Superwarm

- 100m Rope Reel

- 50m Rope Reel

- Polyester Ropes

- Control Lines

- Double Braids

- Braid On Braid

- Anchor Lines & Ropes

- Spools & Reels

- Windsurfing

Mini Spools

- Single Block

- Double Block

- Triple Block

- Soft Attach

- Split Rings & Pins

- Inspection Hatches & Covers

- Bungs & Sockets

- Rudder & Tiller Parts

- Bushes & Fairleads

- Marine Screws

- Penny Washers

- VHF Aerials & Antennas

- Marine Tapes

- Traveller Systems And Parts

- Traveller Blocks

- Pico Hull & Deck Fittings

- Hull & Deck Fittings

- Laser Boats

- Laser Sails

- Laser Sail Packages

- Laser Spars

- Laser Rig Packages

- Laser Foils

- Laser Hull & Deck Fittings

- Laser Ropes

- Laser Dinghy Covers

- Devoti ILCA Boats

- ILCA Sail Packages

- ILCA Rig Package

- Devoti D-Zero Boats

- Devoti KDK Boats

- ILCA Charter Boats

New Devoti ILCA

Search our chandlery

Harken 8:1 Mainsheet System

Read full product description.

Explore more products with the Pulley Block product type.

Fast FREE UK SHIPPING* More info

Price Match Promise How it works

We want you back on the water as quickly as possible. We ship orders quickly, use fast postal services and show you accurate stock levels. This is why our customers rate us as 5 star.

Use our flexible payment options and take advantage of 90 day returns if you need to.

Related Products

Related Categories: Everything No Boats , Harken Most Popular , Harken Wire Blocks , Most Popular , New at Sailing Chandlery - Quality Sailing Items , Online Dinghy Chandlery

- Product Information

A Harken 8:1 mainsheet system complete with top and bottom block. This system is popular for beach catamarans for their mainsheet systems.

Included are the Harken 2632 and Harken 2654 blocks.

Please note, this does not include the rope. It is likely that this product will have a lead time from Harken.

HARKEN 5 YEAR WARRANTY

Harken HARKEN 5 YEAR WARRANTY

Harken kit is built to last and comes with a 5 year warranty.

Harken warrants the original purchaser that each Harken product, when properly installed, used and maintained, will be free from defects in material and workmanship under normal conditions of use, from the date of receipt of the product by the final customer.

Why Sailing Chandlery?

FAST Dispatch

5 Star Customer Rated

90 Day Returns

Customer Reviews

Delivery and costs.

We try to treat delivery as a pass through cost and keep the cost to you as low as possible, on top of our already competitive product prices.

We offer free UK standard delivery for orders over £95 which includes most items. This does not include boats, trolleys, masts, booms, rig packages and large items which can't be sent via standard mail.

Any order placed by midday will leave us the same working day unless there is a lead time which we detail on the product page. We do not ship over the weekend or on bank holidays.

Delivery Costs

UK Royal Mail 2nd Class Delivery (2-5 days) - £4.50

UK Royal Mail 1st Class Delivery (1-3 days) - £5.50

DHL UK Mainland Next Day Courier - £8.99

Medium Length Item (items over 1m long) - £15

Courier - Long Items - Masts, Booms, Rig Packages etc - £40

European Shipping - £25 (upto 5KG) - £35 (upto 10KG)

International Shipping via DHL - From £75

Boats, trollies and trailers - These items cannot be sent using a post service, they have to be collected or delivered by our van. We can provide a custom delivery quotation if you can provide us with your post code. Please note, these items cannot be delivered outside of the UK. Please phone 01268 222912 for a delivery quote.

Deliveries sent outside of the UK may be subject to duties and tax on import.

We can ship to other locations across the World.

If you would like to order an item and can't see your location simply drop us an email to [email protected] with the items you are planning on ordering and your address, we can then arrange a delivery quote for you.

Frequently Asked Questions

Some frequently asked questions that other customers have asked us.

What is the quantity for ropes?

We sell rope by the metre, the quantity is in metres. If you order 5 items you will receive one 5 metre continuous length of that specific rope.

How do I claim a discount?

All of our products are already competitively priced and provide excellent value. If you want to be the first to know about additional promotions simply sign up to our newsletter and we'll send you our offers to your inbox.

Do you ship to other locations?

As standard we ship to the UK, Ireland, USA, Canada, UAE, Australia and New Zealand.

We are always happy to provide you with a quote for shipping to other destinations, simply drop us an email to [email protected] with the items you are planning on ordering and your address. We can then work out a shipping quote for you and arrange payment for your order.

Who are Sailing Chandlery?

We're a team of sailors who are passionate about keeping you sailing and providing an excellent service first time. Find out more .

Have another question? You can call the team on 01268 222912 or email us [email protected]

Our small but dynamic team at Sailing Chandlery are here to offer you the best support for your sailing. As a team we are passionate about giving you the service you deserve and getting you back on the water quickly. Find out why our founder Andrew started the business.

What our customer say about us

Don't take our word for it, see what our customers say about Sailing Chandlery and the service we provide

Sailing Chandlery

Great service.

Called SC to get advice on a piece of deck hardware. Was provided with good advice, items were in stock, good value and despatched same day. I was back racing for the weekend. Thank you

I use Sailing Chandlery because they are consistently good

I use Sailing Chandlery because they have a good range at fair prices. If I need to call Sailing Chandlery staff have great product knowledge & despatch items promptly too 😀

First experience of Sailing Chandlery…

I’ve never used Sailing Chandlery before but I certainly will again. It was very easy to place my order on line and better still the item I wanted was in stock in the correct size. Communication with the company was excellent and I was kept well informed about the status of my order. The goods were delivered very promptly and well packaged. Thank you

Super fast delivery and a wide variety…

Super fast delivery and a wide variety of items so I got everything I needed the next day.

SIGN UP TO OUR NEWSLETTER

Save up to 40% on your next order.

By Product Categories

Small Boat Blocks

Big Boat Blocks

Complementary Hardware

Travelers & Genoa Leads

Mainsail Handling

Headsail Handling

Mooring Solutions

Spare Parts

Accessories

Sportfishing

Fly Soft-Attach Blocks

Carbo Air Blocks

Small Boat Classic

Flip-Flop Small Boat

GP Catamaran Ceramic Mainsheet Systems

Protexit™ Exit Blocks

Through-Deck

Wire High-Strength

Dinghy Vang

Small Boat Deck Organizers

Midrange Classic

Midrange Deck Organizers

Zircon Blocks

Element Blocks

Black Magic Air Blocks

Cruising ESP Blocks

Megayacht Blocks

Stainless Steel Blocks

Black Magic Air Runners

FlatWinder Powered Blocks

Mastbase Blocks

Over-the-Top

Crossover Blocks

Big Boat Deck Organizers

Cam Cleats & Kits

Cam Cleat Accessories

Cam Cleat Bases

Stand-Up Bases

Deck Organizers

Spinnaker Pole Cars

Soft Attachments

Fixed Padeyes

Removable Padeyes

Bolt-Down Fairleads

Grand Prix Jib Leads

Halyard Tensioners

Tiller Extensions

Peter's Desk Drawer

Dinghy Jib Leads

Crossbow Pivoting Self-Tacking Jib Traveler

13 mm Micro

22 mm Small Boat

27 mm Midrange

32 mm Big Boat

Windward Sheeting

42 mm Mini-Maxi

T-Track Genoa Lead

Access Rail System

13 mm AA Battcar System

22 mm A Battcar System

27 mm B Battcar System

32 mm C Battcar System

18 mm Switch Battcar System

26 mm Switch Battcar System

26 mm Trysail Switch

32 mm Switch Battcar System

32 mm Trysail Switch

40 mm Switch Battcar System

40 mm Trysail Switch System

Furling Mainsail Outhaul Systems

Harken Vang-Master

Carbo Racing Foil

Small Boat Furling

Small Boat Underdeck

Reflex Furling

MKIV Jib Reefing & Furling

MKIV Underdeck Jib Reefing & Furling

Furling Accessories

Powered Furling

MKIV Ocean Furling

SnubbAir (Not a Winch)

Grand Prix Winches

Air Winches

Circuit Breakers

Analog Switches

Digital System Switch

Aluminum, Chrome & Bronze Winch Handles

Carbo OneTouch Locking Winch Handle

Service Kits

CLR Mooring Winches

Electric Captive Reel Winches

Hydraulic Captive Reel Winches

UniPower Radial

Single-Acting Integral Backstay Adjuster

Single-Acting Cylinders

Locking Cylinders

Double-Pull Cylinders

Grand Prix Cylinders

Hydraulic Cylinder Rod End Blocks

Hydraulic Cylinder End Fittings

Control Valves

Control Manifolds

Control Panels

Compact Control Panel

Rotary Pumps

Hydraulic Pump Handles

Power Systems

Repair Kits

Ball Bearings

Block Spare Parts

Traveler Cars

Furling Spare Parts

Winch Spare Parts

Winch Service Kits

Marine Grip

Jeep/Truck tops

Garage storage

By Type of Sailing

Dinghy / One-Design

Offshore Racing

Coastal / Day Cruising

Bluewater Cruising

Megayachts / Custom

Service Guide

Tech/Service

deck layouts

Data Sheets (SDS)

How to choose

System diagrams

Calculators

Reeving diagrams

Traveler Purchase Selection Guide

How to Choose

Testimonials

Hoister Videos

- Harken at the front

- Safety & Rescue

/ One-design deck layouts

A-Class Catamaran Deck Layout

The 2:1 outhaul system controls the shape of the foot of the main. Upwind, a tight outhaul flattens the foot. Loosening the outhaul increases the draft for light air or off wind sailing.

The 12:1 cascaded cunningham controls luff tension at the leading edge of the sail. Contained in a compact package inside the spar, the double-ended system allows crew to quickly power or depower the sail from the trapeze.

A 40 mm Carbo Ratchamatic® controls this powerful 8:1 system. The ratchet mechanism in the sheave automatically engages as loads increase. When eased, the ratchet automatically disengages, allowing unloaded sheets to run out instantly during mark roundings and jibes. The lower block rotates so the sheet follows the driver on both tacks.

Mainsheet Traveler

The primary use of the mainsheet traveler is to de-power the boat when sailing downwind. This 2:1 system lets the car run downhill rapidly, but still has the muscle to haul the car to weather.

If you would like to link to or reprint this article please contact [email protected]

Class History

"Talk about fun, at 75 kg (165 lb) with a 9 m (30 ft) mast, the A Cat is one of the most amazing boats on this planet. This is the result of a very simple box rule that only measures four things; length, width, weight and sail area. They are so slippery; you fly up wind silently and can tack through 70 degrees. Downwind they are fast, lively, and loose. Above 9 knots downwind you sit on centerline, fly a hull and send it. The A Cat may be easy to sail, but very hard to sail well. It is an apparent wind game. Being so light it accelerates/decelerates quickly. The good guys are trimmed right and going; make one mistake and they are gone. I have a very high regard for the cat sailors here and foster no false illusions of how challenging this regatta will be. It will make me a better sailor, I know that much. This reminds me of learning how to sail and race 18-footers ten years ago; we thought we'd never learn. It is going to be fun watching all the cat legends perform: Pete Melvin, Glenn Ashby, Randy Smyth, Lars Guck, Scott Anderson, Mike Drummond, Luc du Bois, Mitch Booth, Charlie Ogletree, Jay Glaser, Pease Glaser and more." —Howie Hamlin

Links A-Class Cat Association McLube™ Harken Canvas

Boat Specifications

Minimum weight: 75 kg (165 lb) Maximum boat length: 5.49 m (18 ft) Maximum width: 2.30 m (7.5 ft) Maximum sail area including mast: 13.94 sq. m (150 sq ft)

Related products

16mm Forkhead Block

16mm In-Line Exit Block

16mm Through-Deck Block

16mm Block — Swivel

29mm T2 Soft-Attach Block

40mm Quad Block

40mm Triple Ratchet Block — Swivel, Becket, Cam Cleat, 29mm Bloc…

Standard Cam Base — Swivel, Bullseye, 365 Carbo-Cam

Standard Carbo-Cam® Kit — X-Treme Angle Fairlead

22mm Car — Fixed Sheaves, Eyestrap

22mm Double Block

22mm Through-Deck Block

22mm Triple Block

22mm Heavy-Duty Endstops — High-Beam, Set of 2

22mm High-Beam Track — 3.6 m

Standard X-Treme Angle Fairlead

29mm Pivoting Lead Block — Carbo-Cam® cleat

Product categories.

- United States

- New Zealand

- United Kingdom

Build , Life

Carbon fibre lightweight ‘A class’ catamaran

By telleropnul, November 22, 2020

New project: A Class catamaran (2004 German Aicher-Egner Flyer / AUS849 / Saarberg) Ian Johnson, Merricks Beach, VIC Australia Saarberg skinny boards, Mackenzie Composite Carbon Rudders/Boxes, Harken Mainsheet System, Saarberg mast, Fiberfoam beams, Brewin big head sail, big beach wheels, bum pads, bags boat cover. 5 Altona Street

The easiest way to distinguish the German Flyers to the Auscat Flyers is in the beam connections. The front beam in the Auscat sits on top of the hull (aluminium) while the German one sits more flush (bonded carbon).

aclass002.pdf – Harken – A Class – 2015 Cascade mainsheet system aclass003.pdf – Tips on Sailing the A Class cat aclass004.pdf – Landenberger Tuning Tips – Mast Setup aclass005.pdf – A class tuning guide v3 Greg Goodall aclass006.pdf – Tying Fibrefoam battens aclass007.docx – Brewin Sail Tuning, Care and Rigging aclass008.pdf – How sails work by Paul Bogataj aclass009.pdf – Nacra A2 A class catamaran Rigging and Tuning guide aclass010.pdf – Very general info aclass011.pdf – Tuning your DNA

+1 Fine line tape / edge line tape. You can’t get the same result with just masking tape. Leave in place for both primer and topcoat and remove after final coat has been applied.

Am using marine grade ‘below the waterline’ 2 part epoxy primer and polyurethane topcoat. Quality paints contain chemicals (VOC solvents) that are absorbed through skin. Positive air pressure hood, coverall and disposable gloves mandatory.

Trojan paint mixer (40cm long, small propeller). Fits battery operated drill.

Norglass 2 part Epoxy primer. 2:1 ratio. Makes 1 Liter combined. 10%-15% thinning. Simply mix all together; no measuring required. Use a mixer. Seal container between coats. Mohair roller. Enough to cover both hulls bottoms and sides.

Base coat (primer).

Manual wet sanding using 240 grit paper, spray water bottle and sanding block. This only takes minutes and is actually fun to do. Do not skip this step. Sheet sander and orbital sander have holes in the plate to suck in dust and do not like water (damages bearing). Also mains voltage and water = electrical hazard.

Move paint roller in slow steady movements with light pressure using short strokes keeping a wet-on-wet edge and move sideways along the hull. Keep roller horizontal at all times (move up-down, not left-right) and avoid drips at bottom.

Apply a second coat after 1-2 hours when touch dry without sanding. Leave masking tape in place. Be careful as a still tacky first layer of topcoat can glue to a near-dry roller and take out small chunks.

First topcoat:

Second topcoat:

Replacing black plastic tonneau lacing buttons with stainless steel. Stainless pop rivets M4x20 were not going to cut it. Changed to allen key M5 bolts/nuts and drilled out lacing buttons slightly to match.

2004 German Aicher-Egner Flyer Trailer rego: FB6556 Trailer VIN: 6FFRC181092000326 1992 REDCO ATM UP TO 1.02T BOAT TRAILER, TARE 100, ATM 750, CLASS 25 Hulls: 5.4m length Maximum boat speed: 14 knots. No more than 200 nautical miles Sail number: AUS849 Australia Sailing (AS) number: 618812

4m 4m 4m = 12m 5 wire

trailer plug brown -> 2x tail lights yellow -> 1x left turn white -> 2x ground green -> 1x right turn red -> 2x brake

Rim: Velox 3.50B x 10 cast aluminium Tyre: Duro HF249 5.0-10c Tubeless Trailer -> change to 145/10 or 150/10 mini radials

roller pin 240x16mm assortment cotter pins lacing buttons / tonneau hooks dyneema blue 2 meter

Nairn Inspection Port – Polypropylene ABS white Outside Diameter(145 mm): Inside Diameter(102 mm): Cut out (112 mm): Mount Screws(mm): 6 countersunk Moulded nylon construction with screw in centres Weatherproofing ‘O’ ring seal and wide caulking flange

EVA foam 60-75 kg/m3 blue 10mmx330mmx300mm for cradle and front beam support. Clark Rubber has 25mm+ thick EVA foam in fitness and learn-to-swim isles. 40mm od round tube 3mm wall + jockey wheel clamp for height adjustable cradle support post. Bostik AVS AV515 moisture curing polyurethane adhesive for gluing EVA foam

angle grinder flapper disk angle grinder wire wheel +1 drill brush hard plastic (drill is more versatile than angle grinder; removes grime from cold galv steel without damaging coating).

The inital goal was to sand off the blotchy faded in places blue topcoat to expose -what I thought was- white gelcoat and buff it.

[!] Gelcoat or paint won’t cover up any problems under it only highlight them. Prep is the whole / total key to a nice looking paint job.

Makita 9924DB 76mm corded belt sander 120grit belts. Wet sanding to reduce dust. Unclog belt with garden hose. Alternate five belts to allow belts to cool down and dry to prevent the backing from leaving black streaks.

AEG 300W corded random orbital sander 80 grit (yes, that is what worked best for me somehow and was not too aggressive) for curved bottom of hull. decided not to flip the boat over. lastly a light sand with 120 grit for pre-paint finish.

You can’t sand off blue top coat to expose white gelcoat and then wet sand and buff it. You will likely end up with what you see in pictures. The correct solution would have been to roughen blue paint and add another dark blue color polyurethane top coat. Or if you want white, very carefully (= orbital sander exclusively) only sand off the dark blue color and repaint with white polyurethane. This is however near impossible and will take days of sanding with fine grit paper. It is very difficult not to end up with a patchy result where the fabric weave is exposed (very bad) in places.

Boat hull layers

You start with a mold. Then PVA mold release spray or wax. Then a single thick layer of gelcoat that cures to tacky consistency, Then you lay up your fibreglass or carbon fibre weave using a vinylester / polyester resin. This will seal the tacky gelcoat, infuse the fabric weave and make it cure airtight and non-porous.

So you end up with a mix of:

- Fabric weave (fiberglass or carbon fibre)

- Vinylester / polyester resin.

- Polyester Gelcoat

Instead of a thick layer of white gelcoat you can use clear gelcoat (or just resin) for that nice carbon fibre fabric look. Or you can just paint your resin fabric weave. Paint is typically used for non-mold applications. Paint coats are thinner so less weight, don’t yellow in UV, are harder, may be suitable for below the waterline (water osmosis) but are more easily scratched and scuffed and more difficult to touch up than gelcoat.

- Epoxy “high build” primer

- Epoxy “sealer” primer

- Polyurethane top coat

The layers I can see in the pictures:

- BLACK – resin infused carbon fibre

- CREAM WHITE – most likely gelcoat if vinylester / polyester resin was used on carbon weave.

- SALMON – bondo filler on repair jobs.

- GREY – epoxy primer

- WHITE – polyurethane top coat.

- BLUE – original owner mentioned this was a special low friction paint, likely a polyurethane topcoat.

Carbon fibre

You aren’t painting carbon fibre, you are just overcoating the resin that was used to infuse the fabric weave. Of course if you sand down to the fabric weave itself, which is to be avoided , then there is some exposed carbon fibres. Exposed carbon (graphite) fibre weave that has no resin on it is kind of slippery and does not stick well to epoxy primers. It should stick to gelcoat:

Your typical polyester gelcoat will only adhere to fiberglass / carbon fibre, previously cured gelcoat, or polyester resin.

Never use sandpaper any coarser than 320 grit to sand finishing materials between coats. Never wet-sand any topcoat with less than 1200 grit wet/dry paper (really?) Do not use any stripper containing methylene chloride (aka methylene dichloride or dichloromethane). It will attack gelcoat severely.

Gelcoat is a liquid that hardens to form a thick layer that is used to protect fiberglass and give it a shiny, smooth finish. As gelcoat ages, it becomes porous. The more porous it becomes, the more easily it stains, the worse it looks and the harder it is to clean. Wet sand with soapy water to lift the dirt.

don’t use:

- brake fluid

- paint stripper

- scouring pad

- steam cleaner (boiling steam bubbles gelcoat)

- heat gun (can blister and discolour exposed gelcoat)

- orange/citrus stripper (leaves orange peel film)

- soda blasting (leaves 60 grit finish).

- dustless blasting (fine 40-70 recycled glass; leaves 100 grit finish)

- pressure washer with paint stripper nozzle (damages gelcoat)

- belt / random orbital sander and elbow grease.

- if the gel coat is sanded through and the strands of the fabric show, this needs to be sealed with resin or body filler. Repairs such as these should always be sanded and blocked smooth before laying down your first coat of primer.

Paint over gelcoat:

- epoxy primer

- polyurethane top coat

Gelcoat over Epoxy primer or Epoxy resin:

You should use a vinylester or polyester resin in your fabric weave if you want to bond with polyester gelcoat. Can you use a gelcoat on an epoxy resin or epoxy primer ? Yes, but you shouldn’t.

https://www.epoxyworks.com/index.php/applying-polyester-gelcoat-over-epoxy/

- you need to take extreme care about surface preparation. water and dishwashing soap + scotchbrite to remove amine blush, dirt and grease (no pressure clean) > let completely dry [!] > acetone paper towel multiple passes

- you are better off applying a ‘below the waterline’ suitable polyurethane topcoat over epoxy primer.

Gelcoat over gelcoat / gelcoat repairs:

- Gelcoat is much thicker than paint, which is great for areas prone to scuffs and scratches.

- Simply wet sand, buff out and scratches disappear.

- Gelcoat fades in sun. Mostly noticeable when you spray fresh gelcoat.

- Gelcoat is perfect for small repairs. You can dab it in with a brush or stick.

- Gelcoat is used as the first layer in a waxed polished hull mould and built up with fiberglass or carbon fiber. When the mould is ‘popped’ the gelcoat comes out polished shiny.

- Gelcoat is really formulated for application to a contact moulding surface, not spraying.

- When you (re)-apply gelcoat to a boat hull, it will cure with an orange peel skin and is not smooth. you will need to:

- wear gloves, suit, respirator

- apply gelcoat (brush, roller or spray)

- (sand with 180 – vacuum, random orbital sander)

- wet sand with 320 – use soapy water spray bottle or garden hose nozzle. no bucket.

- wet sand with 500

- wet sand with 800

- polish with Strata cutting creme

Curing gelcoat:

- Gelcoat is not a paint. It is a polyester resin that uses Methyl Ethyl Ketone (MEK-p) catalyst to cure (1.5-2%)

- The first layers remain tacky if exposed to open air and can be applied 20 minutes apart.

- The final layer requires either PVA sealant spray, gelcoat with wax added that sits on the surface or clingfilm / mylar overhead projector sheets to form an airtight seal to aid in the curing process.

- Buy gelcoat without wax so you can laminate multiple layers (tacky) and seal with PVA mold release spray for airtight curing of the final layer.

How to gelcoat:

- Test the procedure on a test piece.

- To get the gelcoat out of a 4L tin into a 100ml mixing cup, hold the mixing cup above the 4L tin and use a stirring stick to drizzle gelcoat into the container like you do honey in a cup of tea. This keeps the 4L tin edge clean. Put a bit of masking tape high up on the side and over the edge of the mixing cup, so any drizzled uncatalyzed gelcoat near the rim of the mixing cup can be removed easily. Remember: any uncatalyzed gelcoat that has not come into contact with MEKp hardener will not set. You want all gelcoat at the bottom of the mixing cup only.

- Large areas need to be sprayed with a HVLP gun and large powerful air compressor.

- Lay up multiple thin coats in short succession. Don’t apply a thick coat in one go.

- If you brush, get brushable gelcoat and apply criss-cross strokes and blow air over it to flash off.

- Clean with acetone. All surfaces must be clean, dry and free from grease, wax, oil, and other foreign matter.

- Always mix in small batches. Generally mix one-pint batches. 100ml – 250ml with 1.5% mekp (syringe)

- Buy your gelcoat from a quality composites shop and check the manufacturing date/time.

Thinning gelcoat

- Don’t even think about spraying it without styrene but no more than 10%.

- Do not use acetone.

- Do not use Duratec below water line.

- You can add 10% styrene monomer (not to be confused with styrene wax) to thin gelcoat, but it is known to cause gelcoat to yellow if you go 10%-20%. it can introduce other chemical problems like peeling from surface, shrinkage, bonding, not curing.

- Alternatively you can add 5% – 10% MEK (not MEKp) to thin gelcoat.

https://blog-fgci.com/2017/09/05/how-to-apply-gelcoat-the-end-all-guide

https://www.boatus.com/magazine/2018/august/topside-gelcoat-repair.asp

Use a gelcoat cup gun to spray gelcoat. Alternatively use a High Volume Low Pressure HVLP spray gun.

- new ones come coated with oil; thoroughly clean before first use.

- fan fully open, paint trigger fully open, air intake fully open.

- use a pressure regulator at the gun set to 2 bar / 29psi.

- will spray at around 10-12 psi at the nozzle, but still usually require 30 psi at the gun itself.

- 1.5 Hp. single head, 20 gallon (= 75 liters), 45 psi compressor for repair work. Can barely spray continuously a 10 square foot (= 1 mtr2) panel even when the gel coat is thinned.

- 5 Hp two head, 100 gallon (375 liters), 90 psi compressor that can spray gel coat on 20-25 footer boat.

- size tank determines how often compressor kicks in. psi rating determines how quick the tank re-fills.

- spraying with HVLP gun will put a lot of stuff in the air quick in an enclosed space.

gelcoat white MEK-p (1% – 1.5%) MEK or styene to thin gelcoat (8%) 2.5mm nozzle High Volume Low Pressure (HVLP) gravity fed (= reservoir sits on top) spray gun with pressure pressure gauge / regulator at the gun (2 bar / 30 psi). large tank high pressure aircompressor measuring cup syringe acetone disposable gloves solvent resistant paintbrush pva mold release glasses, suit, gloves, respirator 7-10 minutes working time

Failed attempt #1

Foam brush application of gelcoat with mylar sheets.

I used mylar A4 overhead projector sheets and foam brushes to apply polyester gelcoat. 100ml gelcoat = 122 grams = 1.5ml MEKp

- Gelcoat finish as a result of mylar sheets is perfect , similar to a mold finish.

- Mylar sheets would work perfect on flat surface small repair jobs.

- Every batch hardened perfectly.

- black carbon fibre patches would be visible through the white gelcoat when gelcoat is applied at the correct thickness.

- Mylar does not wrinkle but ripples as a result of curvature and use of squeegee.

- No 100% airtight seal around mylar sheet perimeter, even when covering the perimeter with masking tape:

- I started pushing the gelcoat out from underneath the mylar sheet to compensate, which worked better but resulted in small flakes lifting from the final smooth surface when I tried to sand it down.

- Foam brushes dissolve in acetone. One-time use only.

- 100ml batches = lot of batches = lot of time.

- one batch covers 2 A4 size mylar sheets but is still very thick and does not flash off compared to spraying multiple tacky layers.

- brush on first coat + blow air to flash off + 3 coats criss-crossed + remove tape + place mylar sheet + squeegee air out from center to over the edges = not much time.

- this is not a hole repair; gelcoat was way too thick.

- 1 single coat + mylar = no brush strokes anyway + more working time + thinner layer.

- A next 1% MEKp batch resulted in not hardening for 20 minutes instead of 10. Mixture remained thin and the mylar sheet came off the surface frequently resulting in ‘ant farm trail’ small patches of crenulations / air pockets in the gelcoat. Continued use of squeegee resulted in mylar sheet sticking but an uneven coverage of gelcoat.

- This 1% MEKp batch also showed gelcoat did not bond to blue paint and exposed carbon fibre (resin), most likely as a result of high humidity, low temperature, low catalyst amount or poor surface prep. Mylar sheet was simply ripped off at 11:30am and surprisingly the bits sitting on exposed carbon fibre weave and blue paint had bonded poorly.

- This would take way too long and not produce a good result.

- Squeegee does not provide uniform thickness. Black carbon fibre was visible through gelcoat in places.

100ml gelcoat = 120 grams = needs 1.5ml MEKp catalist applied with a small syringe from drug store / pharmacist. Wear gloves, safety glasses and non-breathing fabric long sleeves when going near MEKp. A single drop in your eye can cause irreversible blindness in 10 seconds.

Left and right patch still covered in mylar sheet hence the gloss and yellow tint. After sanding it actually looked good except for some small flakes coming of near edges of mylar or where there was a poor bond.

2 part epoxy primer with thinner and 2 part polyurethane topcoat with thinner, mohair roller application.

“Don’t cling to a mistake just because you spent a lot of time making it”.

A comforting thought: you can always just sand it off again. Decided to remove it all and sand back to where I started from.

Alexseal Topcoat Reducer Brush R5015 Alexseal Topcoat Converter Brush C5012 Alexseal 501 Topcoat White T91xx Alexseal rolling additive A5018 (you can see the air bubbles pop for a super smooth finish).

Can’t source these materials locally unfortunately. Specialty paint store had this instead:

Best to buy from a shop rather than order online in case you need more. This comes in 500ml, 1ltr and 4ltr tins that are in stock. Thin 10% for roller application.

Do not use foam roller. Do not use cloth roller. Do not use microfibre roller. Use mohair roller. Wrap mohair roller in masking tape and unspool to remove lint.

- Lyrics, texts, etc.

- Professional Development

Did you know...

Ambition is like a frog sitting on a Venus Flytrap. The flytrap can bite and bite, but it won’t bother the frog because it only has little tiny plant teeth. But some other stuff could happen and it could be like ambition.

| ASX | 09 Nov 23 263k (20k) → 283k | Z411 |

| Getz | 09 Nov 23 175k (20k) → 195k | Z79A |

| D22 | 11 Feb 24 144k (7k) → 151k | Z89A |

| 800XCX | 15 Jul 21 17k5 (15k) → 30k | KN204 |

- Do Pobrania

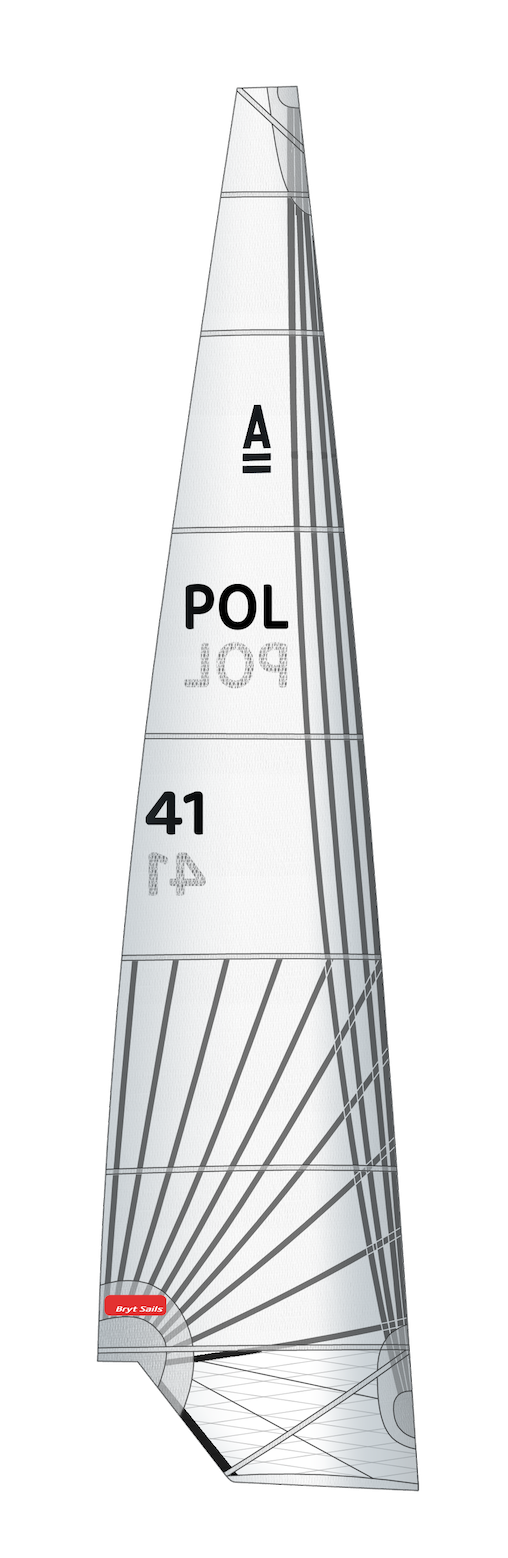

A-CLASS OPEN

1st at the A-Class Catamaran World Championships 2023, Toulon

Our team rider, Jakub Surowiec , recently won the World Championships, adding the final golden medal to his impressive collection, which already includes silver and bronze.

A-Class Catamaran 2023/2024 Bryt Sails standard decksweeper mainsail

The Bryt Sails Mainsails are designed for foiling. Sails provides easy power control for foiling downwind and upwind. Many test hours and much attention has been paid to make sure sails keeps up with the class trends and follows sailor’s expectations in all weather conditions. Bryt Sails A class sails are developed with the collaboration of the Exploder team riders.

Sail design is based on the successful 2021 model, but optimized for upwind foiling as A-cat platforms now offer effective foiling performance all around the racecourse. Main target was to improve twist profile and adapt depth of the sail for higher speeds, but still maintain power in downwind legs and light wind conditions.

For 2023 the bottom section was redesigned with a large window. We also added more leech shape to maintain some of the power in the light conditions, when cunningham is released. All 2023 Bryt Sails now feature cutaway clew for more space to move from side to side, trying to keep foiling during the tack. From 2023, Standard models are unchanged.

This is Standard model which is suitable for <78 kg sailor, also depends on the skipper’s performance. If you are looking for easy to power up set up, check Bryt Sails standard decksweeper mainsail.

- 9+1 Fiberfoam battens

- Easy access leach velcro for bottom batten

- Head ring to hook the sail

- Available in Contender Maxx EnduMax GP or Maxx Racing sailcloth, both with carbon stringers

- Cutaway clew for easier side to side access

- Measurement certificate

- Country code

- Sail number

Compatibility:

A class catamaran is a development class. The sail design supports large variety of mast and boat set ups. If your boat differs from any dimensions below, or you have any individual request please note that when placing your order.

- 9m long Saarsberg, Fiberfoam Standard or Tapered mast

- 192 cm distance from mast to main traveler track

- 110 cm distance from mast to trampoline mainsheet block

Also please let us know your body weight and height so we can make sure the sail is the perfect choice for you!

Contact details:

SAIL – 1650 euro net Transport in EU – 150 euro net

A-Class Catamaran 2023/2024 Bryt Sails standard+ decksweeper mainsail

Sail design is based on the successful 2021 model, but optimized for upwind foiling as A-cat platforms now offer effective foiling performance all around the racecourse. Main target was to improve twist profile and adapt depth of the sail for higher speeds, but still maintain power in downwind legs and light wind conditions.

For 2023 the bottom section was redesigned with a large window. We also added more leech shape to maintain some of the power in the light conditions, when cunningham is released. All 2023 Bryt Sails now feature cutaway clew for more space to move from side to side, trying to keep foiling during the tack. From 2023, Standard+ models are unchanged.

This is Standard+ model which is suitable for over78 kg sailor, also depends on the skipper’s performance. If you are looking for easy to control set up, check Bryt Sails Standard decksweeper mainsail.

- Available in Contender Maxx EnduMax GP or Maxx Racing sailcloth, both with carbon stringers

SAIL – 1650 euro net Transport in EU – 150 euro net

A-Class Catamaran Bryt Sails Pro2024 decksweeper mainsail

The Bryt Sails Mainsails are designed for foiling. Sails provides easy power control for foiling downwind and upwind. Many test hours and much attention has been paid to make sure sails keeps up with the class trends and follows sailor’s expectations in all weather conditions. Bryt Sails A class sails are developed with the collaboration of the Exploder team riders.

Pro model evolved from the Standard model. For 2024 we used Standard+ luff characteristic for more power. Smaller top lowers the center of effort, what results in easier heel control and less aerodynamic drag.

All 2023 Bryt Sails now feature cutaway clew for more space to move from side to side, trying to keep foiling during the tack.

This is 2023 Worlds winning model of Jakub, and refined 2022 Promodel, 3rd at the 2023 Europeans.

Pro model 2024 is made for brave sailors, who are always looking for more speed. Smaller top reduces drag, however makes it more difficult to pop-up the hull in light conditions. If you are looking for an easier to power-up set up, check Bryt Sails Standard and Standard + decksweepers mainsails.

- New 2023 bottom design with large window and cutaway clew for easier side to side access

Bryt Sails 3/4 Boat Cover

The Bryt Cover is designed for Exploder A cat catamarans. It protects essential parts of the boat that can be weather effected: trampoline, anti-slip foam, rudder system. Cover is made of super reliable waterproof cloth MASACRIL. There are 2 full boat-wide buckles that keep your boat covered on the most windy days, just don’t forget to tighten your boat down 😉

● Waterproof durable cloth MASACRIL ● Available in different colors (masacril) ● Full trampoline + rudder system protection ● Mast + compass sleeve ● “Over the top” rudder cassette cover ● Personal print available (sail number, boat name etc..)

A class catamarans vary in the mast, beams and sidestays positions. This cover is designed for 2020-2023 Exploder Ad3. It should fit 2016+ Ads Exploders as well.

190 euro net

A-CLASS RESULTS

2023 victory, a class world championship , yaqcht club toulon/france.

1st – JAKUB SUROWIEC

GERMAN NATIONAL CHAMPS , MALCESINE/LAKEGARDA

Polish nationals , sopot, 2022 victory, world championship, houston.

2nd – JAKUB SUROWIEC

9 – JACEK NOETZEL

SPRING CUP , ARCO

1st – TYMOTEUSZ BENDYK

A-CAT EUROPEAN CHAMPIONSHIP 2022 , ARCO

3rd – JAKUB SUROWIEC

5th – TYMOTEUSZ BENDYK

Easter regatta, Campione del Garda

1st- TYMOTEUSZ BENDYK

Gdynia Sailing Days, Poland

2nd- TYMOTEUSZ BENDYK

Błękitna Wstęga Zatoki Gdańskiej, Poland

Sopot catamaran cup , poland.

1st – TYMOTEUSZ BENDYK

MISTRZOSTWA POLSKI A CAT , SOPOT - POLAND

1st – JAKUB SUROWIEC

2nd – TYMOTEUSZ BENDYK

3rd – JACEK NOETZEL

WINNING THE A-CLASS POLISH CUP FOR THE 2022 SEASON, POLAND

JACEK NOETZEL

2021 VICTORY

Univela trophy , campione del garda, dutch nationals , hellecat, easter regatta , campione del garda, gdynia sailing days , poland.

1st – JAKUB SUROWIEC

2nd – TYMOTEUSZ BENDYK

GERMAN NATIONALS

2020 victory, 3 mola sopot , poland, 2019 victory, world championships , weymouth uk.

3rd – TYMOTEUSZ BENDYK

Winning the A-class Polish Cup for the 2019 season

TYMOTEUSZ BENDYK

By Product Categories

Small Boat Blocks

Big Boat Blocks

Complementary Hardware

Travelers & Genoa Leads

Mainsail Handling

Headsail Handling

Mooring Solutions

Spare Parts

Accessories

Harken Canvas

Sportfishing

Fly Soft-Attach Blocks

Carbo Air Blocks

Small Boat Classic

Flip-Flop Small Boat

GP Catamaran Ceramic Mainsheet Systems

Protexit™ Exit Blocks

Through-Deck

Wire High-Strength

Dinghy Vang

Small Boat Deck Organizers

Midrange Classic

Midrange Deck Organizers

Zircon Blocks

Element Blocks

Black Magic Air Blocks

Cruising ESP Blocks

Megayacht Blocks

Stainless Steel Blocks

Black Magic Air Runners

FlatWinder Powered Blocks

Mastbase Blocks

Over-the-Top

Crossover Blocks

Big Boat Deck Organizers

Cam Cleats & Kits

Cam Cleat Accessories

Cam Cleat Bases

Stand-Up Bases

Deck Organizers

Spinnaker Pole Cars

Soft Attachments

Fixed Padeyes

Removable Padeyes

Bolt-Down Fairleads

Grand Prix Jib Leads

Halyard Tensioners

Tiller Extensions

Peter's Desk Drawer

Dinghy Jib Leads

Crossbow Pivoting Self-Tacking Jib Traveler

13 mm Micro

22 mm Small Boat

27 mm Midrange

32 mm Big Boat

Windward Sheeting

42 mm Mini-Maxi

T-Track Genoa Lead

Access Rail System

13 mm AA Battcar System

22 mm A Battcar System

27 mm B Battcar System

32 mm C Battcar System

18 mm Switch Battcar System

26 mm Switch Battcar System

26 mm Trysail Switch

32 mm Switch Battcar System

32 mm Trysail Switch

40 mm Switch Battcar System

40 mm Trysail Switch System

Furling Mainsail Outhaul Systems

Single Line Reefing

Harken Vang-Master

Carbo Racing Foil

Small Boat Furling

Small Boat Underdeck

Reflex Furling

MKIV Jib Reefing & Furling

MKIV Underdeck Jib Reefing & Furling

Furling Accessories

Powered Furling

MKIV Ocean Furling

SnubbAir (Not a Winch)

Grand Prix Winches

Air Winches

Circuit Breakers

Analog Switches

Digital System Switch

Aluminum, Chrome & Bronze Winch Handles

Carbo OneTouch Locking Winch Handle

Service Kits

CLR Mooring Winches

Electric Captive Reel Winches

Hydraulic Captive Reel Winches

UniPower Radial

Single-Acting Integral Backstay Adjuster

Single-Acting Cylinders

Locking Cylinders

Double-Pull Cylinders

Grand Prix Cylinders

Hydraulic Cylinder Rod End Blocks

Hydraulic Cylinder End Fittings

Control Valves

Control Manifolds

Control Panels

Compact Control Panel

Rotary Pumps

Hydraulic Pump Handles

Power Systems

Repair Kits

Ball Bearings

Block Spare Parts

Traveler Cars

Furling Spare Parts

Winch Spare Parts

Winch Service Kits

Blockheads Gear

Promo & Gifts

Marine Grip

Blue Performance

Jeep/Truck tops

Garage storage

One-design Covers

Boat accessories

Canvas bags

By Type of Sailing

Dinghy / One-Design

Offshore Racing

Coastal / Day Cruising

Bluewater Cruising

Megayachts / Custom

Service Guide

Tech/Service

deck layouts

Data Sheets (SDS)

How to choose

System diagrams

Calculators

Reeving diagrams

Traveler Purchase Selection Guide

How to Choose

Testimonials

Hoister Videos

Request a Quote

Request Samples

Fabric details

Cover Styles

Canvas Videos

Contract Services

Materials and Components

Our Equipment

Contract Cut-and-Sew Project Spotlight

- Harken at the front

- Safety & Rescue

Support / FAQs

Harken GP Catamaran Mainsheet System Q&A with Matt Schmidt, Project Lead

The Harken marketing team sat down with Matt Schmidt, Project Lead for the GP Catamaran mainsheet system, to learn about the story behind this new product.

How was the specific purpose of the GP catamaran mainsheet system and its development different to how you've approached other solutions? We design many of our products for a range of potential uses. The Carbo line, for example, is a universal product that does a good job across a variety of applications. The difference with the GP Catamaran mainsheet system, is that it had to address a very narrow set of design requirements for a very specific customer type. As a result, we had a much longer list of "must haves" than compared with a more universal product. The challenge, of course, is to not only hit everything on the list, but also understand in what order. There's usually a limit as to how many incremental changes can be made in each iteration of a product, otherwise testing can become muddled. So we had to prioritize each element and work through many rounds of prototypes. Thankfully this was made easier due to a much more direct and fast-paced feedback loop with our development partners, allowing us to incorporate quick design revisions and rapidly prototype new iterations for testing on the water. First and foremost on the design list was achieving maximum efficiency. We examined a variety of bearing materials and chose ceramic for the inner and outer race, as well as the ball bearings. The sheave is made from Carbo material that's used in the Carbo line of Harken blocks. Round two focused on how we could make the top and bottom "nest" together more closely than a stock system, improving overall compactness and giving the skipper a few more inches of trim and a tighter leech. Round three focused on the design of the cam-cleat arm. Once the functional requirements were met, we had to break down each component and understand how to manufacturer it most efficiently. This involved further design changes and additions without compromising the core requirements. Finally, once we could produce parts and assemble them, the focus moved to branding the system and designing the packaging. How did the process and relationship of working with sailors on the design of this system evolve? Design solutions often rise directly out of the feedback we receive from sailors who are competing at high levels and looking for that extra edge. These sailors put in hundreds of hours using our products, testing in environments and scenarios only they can experience. It's here, where the margin of success is so narrow, that they notice potential for refinement and improvement that we simply can't in the testing lab. This feedback is incredibly valuable, and from it we can begin to consider the best solutions. The development of this project was certainly much faster-paced, thanks to the open dialogue between sailor and engineer. Collaboration was very fluid overall. We'd often chat with our partners on a daily basis, hearing about training and discussing what improvements could be made. It was not uncommon to receive a text message from our enthusiastic development partners saying "What do you think of this idea? Could you work this up in CAD?," followed by a photo of a sketch on a cocktail napkin. Our end result really came down to the design cycle of: prototype, test, feedback, rinse, and repeat-as often as necessary. As the GP mainsheet system evolved, and on-the-water feedback became more and more direct, we gained a better understanding of what the system did and did not need to do. Eventually, the time came when we had to say GO and have our partner commit to it in its then current form for an important regatta. That was certainly a bit nerve wracking!

At what point are the system and its benefits the most important to the sailor when out on the water? I'll honestly say that every feature we've designed into this product offers unique on-the-water benefits. First and foremost is efficiency. Because this system is easier to trim, the crew can save a fair amount of energy over a stock system. Elite sailors who train deliberately and closely track their stamina will notice this right away. For a development partner who competed in the Florida 300 distance race, it meant the difference between trimming the mainsail all day with one arm instead of two. The ease of trim also translates into smoother crew movements. For instance in the Nacra 17 where most often the crew is the lighter smaller team member, it doesn't require the use of legs or full body lunges to get that extra bit of trim. This equates to less bounce and vibrations in the boat and wind spilling out of the sail. As I mentioned earlier, second only to efficiency is the compactness of the system. This applies specifically to the Nacra 17, where the pin-to-pin distance of the mainsheet directly impacts the maximum mast rake. By closing that margin and getting the top and bottom blocks to nest together more tightly, we effectively give the skipper a tighter leech and the ability to put that much more rake into their rig set up when needed in heavy air. Finally, the new cam arm adjustment offers infinite settings for each sailor. Instead of moving the cam arm between individual holes every 10 or 15 degress, we changed this to a slider track that can be adjusted very slightly for an ideal lead. Better yet, the entire cam arm assembly is contained, so there's no risk of losing parts if a quick on-the-water adjustment is needed. The entire system is serviced with a single 4 mm hex wrench. Simple, easy, low-hassle. How does this system help a team widen the margin at the elite level? Most of this is answered by my last question, but I will try to sum it all up. Competition between sailors at this level is extremely close. Races are decided by inches. The incremental benefits of the GP mainsheet system add up to two important takeaways: 1. Less time and effort spent with the crew's head in the boat, 2. More time with the crew's head outside the boat. What does the future of a product like this look like? It's not exactly off-the-shelf, but it's not totally custom either? Will the design relationship continue with sailors looking toward the next Olympic Games? You could say it's "quasi-custom" maybe, available to those who have the narrow need, but custom in how well it is tailored to the very specific usage environment. We always reexam products and try to improve them, so technically the GP mainsheet system will never be "finished". Other potential changes may come from outside influences, such as improvements in rope technology or via our own block designs like the new Power3 family that offers different sheave profiles to handle a variety of wind and wave conditions. Adding improved components like this may cause ripples in the overall design. Otherwise, if I had to guess, there will be requests to reduce the purchase in the system. Only a handful of boats (Nacra 17, F18, Foiling Phantom) use the current setup of 10:1 and 12:1. So we may "fill out the family" and develop new versions of the same core product for different boats, most likely with lower loads. On an higher level, all of our products benefit from these custom or semi-custom projects. It helps us understand how the technology can be reapplied to other products or for niche applications. Finally, what defines success for this product? We want to sell thousands of cam cleats, but where does a Grand Prix catamaran system factor in? Each project has its own definition of success. For this project, it was creating the perfect solution for this class of sailor and boat. Saleswise, we're very deliberate. For some projects the magic number is 5,000 units in the first year, and for others it's 200. Bottom line - Do we see the Grand-Prix mainsheet system at the front of the high performance cat classes? The Nacra 17 or F18 Worlds? That's certainly the goal. If you would like to link to or reprint this article please contact [email protected]

Product Categories

- United States

- New Zealand

- United Kingdom

Harken will be closed on Thursday, Sep. 12 starting at 11 a.m. for our annual Sail Day. Any orders placed after 3 p.m. Wednesday, Sep. 11 will be processed on Friday.

Social Media

Blog Updates

© 2024 US A-Class Association, All rights reserved.

Secondary address

Related members, related boats.

Event Details

COMMENTS

Harken - A Class - 2015 Cascade mainsheet system. This is the 2152 at the end of the boom. It contains the shackle connecting the outhaul to the clew of the sail. The boom moves freely in between the dyneema rope: This is the second 2152 that bolts onto the metal hoop bracket of the traveller: This is the 2149 closest to the two 2152 blocks.

GP Catamaran Ceramic Mainsheet Systems. Protexit™ Exit Blocks. Through-Deck. Wire High-Strength. Dinghy Vang. ... A-Class Catamaran Deck Layout Outhaul. The 2:1 outhaul system controls the shape of the foot of the main. ... This 2:1 system lets the car run downhill rapidly, but still has the muscle to haul the car to weather. ...

MAINSHEET. Off-the-shelf two-speed racing mainsheet system (3:1 coarse, 6:1 fine) suitable for yachts and sportsboats to 11m (36ft). Pull on both sheets for quick adjustment, one sheet for fine tune. MWL = 800kg (1760 lb) Max Line Size = 12mm (1/2") VARIATIONS Replace RF72700 with RF72900 for yachts up to 12m (40ft).

GP Catamaran Ceramic Mainsheet Systems. Protexit™ Exit Blocks. Through-Deck. Wire High-Strength. Dinghy Vang. Small Boat Deck Organizers. Midrange Classic. Midrange Deck Organizers. ... Access Rail System. Show All. 13 mm AA Battcar System. 22 mm A Battcar System. 27 mm B Battcar System. 32 mm C Battcar System. 18 mm Switch Battcar System.

Mainsheet traveller -centred. Lie close to the mast and over the front beam, keep the transoms out and concentrate on keeping flow on the sail. Light Winds: 4 -8 knots Luff Tension -Just take the wrinkles. Mast rotation -45 deg. Mainsheet -Moderate to firm as the wind builds Foot -Freed about 30mm. Mainsheet traveller -centred

'A' Class Catamaran Association . The official site for the British 'A' Class Catamaran Association. Designed to inform new and existing 'A' Cat sailors about UK 'A' Class trends. ... I have a Harken 40mm 9:1 mainsheet system with 8mm swiftcord, and 2 Harken 60mm auto ratchets to help manage the load. Good gloves are a must, the high aspect A ...

The 'B' class was a 20ft twin hander with 235ft2 of sail and developed into the Tornado and a few offshoots such as the F18. The 'C' class was another twin, but at 25ft with a 300ft2 rig, has become a super sophisticated monster and the pinnacle of small cat design that races for the Little America's Cup.

In this section, you will find explanations, setup advice and some videos about various technical aspects of the 'A' Class Catamaran, all provided by expert sailors and designers to help you to get the best from your boat. It covers both Classic and Foiling designs. ... Mainsheet Systems. bottom of page ...

Mast rake - Remove shock cord return for trapeze ring and attach a 3' or longer line to the trapeze ring. Pull down on line and swing trapeze system forward to forestay chainplate. Hold line and mark where the line intersects the hole in the top of the chainplate. Now swing trapeze system aft and note where the mark on the line intersects ...

DNA Performance Sailing Tutorial about how to set up the pre-tuned mainsheet system. As the F1 A class foiling catamaran comes with a pre-tuned mainsheet sys...

This is our preferred control system with the track bolted to the seat back, and using a double-ended Main Sheet running through clutches to a winch situated at each end. One end can be fixed allowing ... Unfortunately many new catamaran buyers are inexperienced with catamaran design and, quite fairly, look firstly at the French designs. They ...

A Class Cascading Mainsheet System. Article News. 11 October 2015 11 October 2015 mgkopp. Ref attached, with thanks to Grant Pellew, and Harken, our 2016 Nationals sponsor. ... Notice of Race: A Class Catamaran Victorian Championships 2024. 17 January 2024 17 January 2024 mgkopp. Find us on Facebook. A Class Friendly Clubs: NSW.

Mainsheet 2-Speed Systems. These dual purpose systems offer sailors the option of either speed or power. They are used for mainsheets on small to medium-sized offshore boats where power is required for effective heavy-air trimming upwind, but speed is crucial for off-wind trimming and mark roundings. Typical boat length: Small Boat: 22' - 28 ...