- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sails and Rigging

- Maintenance

- Sailing Totem

- Sailor & Galley

- Living Aboard

- Destinations

- Gear & Electronics

- Charter Resources

- Ultimate Boating Giveaway

How to Paint Sailboat Decks

- By Tom Zydler

- Updated: March 14, 2013

Painting a sailboat

Janet Van Leuwen and Steve Van Wig own a Whitby 42. Looking at their beautiful, well-groomed ketch, you’d never guess it was built in 1982. The name on the stern, Lunacy , may be the only hint of the incredible amount of work that the couple has put into rejuvenating their boat. Bringing the decks and the coachroof top to their present glory was a large part of the project, as these tasks would’ve been on any glass boat more than 25 years old. This is how they did it. And frankly, this is how it should be done.

Before the couple could begin doing any prep work for painting, the deck hardware had to be removed. They needed access to tight spaces where the horizontal deck surface turned into vertical bulwarks, around the masts’ partners, near the windlass base, and so on. (They also removed the chainplates, which needed attention as a separate project.) Out came all stanchions, their bases, various padeyes, winches—anything and everything, in fact, that could obstruct the power sanders required to remove the worn-down, cracking, original nonskid pattern. Steve then used silicon sealant to plug all the fastener holes that would be reused; silicon repels paint, so the fastener locations would be visible when they began reinstalling the hardware.

Donning breathing masks and kneepads, the couple spent days grinding the old surfaces with 80-grit discs. Using thick foam pads on machines running at high rpm prevented any gouging in the laminate. Smaller sanders (both round and square) helped them to negotiate tight turns; at times, they resorted to manual sanding blocks. Working with thickened polyester and epoxy resins, Steve filled several hairline cracks and dings. They then sanded this filler with 80-grit, then 100-grit, and finally 120-grit sandpaper to achieve a smoother surface before vacuuming up all the accumulated dust.

Next, to keep paint drips off teak handrails, the windlass, and the portholes, they masked these with heavy paper and tape. Right after the final wipe with a cleaning solvent, they took two days to roll and brush on two coats of epoxy primer, the base for the final topcoat. Over the next few days, the primed surfaces were sanded with 120-grit paper, followed again by vacuuming and hosing the resulting dust. Afterward, Janet cleaned all the surfaces with non-sticky tack cloths designed for multipart polyurethanes.

At this juncture, Steve identified and outlined the future nonskid areas, then spent a couple of days taping their inner edges with long-life 3M masking tape. At the corners, joining short lengths of tape on tight curves required meticulous care. After they wiped everything with cleaning solvent, they applied the first coat of multipart polyurethane to all the surfaces outside the future nonskid. Two more topcoat applications followed within allowable, 16-hour intervals. After sanding with 220-grit paper, dusting, using the tack rag, and wiping the solvent, they rolled and brushed on the fourth and final topcoat. The solvent-resistant, ultra-smooth, high-density foam-roller covers and quality brushes delivered the best finish. Working in the hot Florida sun required frequent additions of brushing reducer.

After allowing 48 hours to fully cure, they removed the masking tape. Fresh tape was then applied along the outside margins of the nonskid areas. All was ready for applying the nonskid coats. But first Steve spent a few days experimenting. He mixed his own color tints—too dark, and you couldn’t walk barefoot on the sun-heated deck; too white, and the deck glare was intolerable.

Also, he tested paint combined with various nonskid additives on scrap plywood; very coarse grit could damage human skin if a sailor knelt or fell on deck. He decided to combine equal amounts of coarse and fine grit. Significantly, this mixture prevented the coarse grit from settling down in the paint in lumps. On the big day, Steve and Janet mixed the activator with the paint base in a large container, added the correct nonskid grit, poured in the brushing reducer, and thoroughly stirred it all. After pouring small dollops within a taped area, Steve spread it out with a roller with Janet assisting, adding more paint or grit as necessary. She also wiped up Steve’s occasional paint drips with a solvent-soaked rag. The work went quickly and smoothly, though constant stirring of the paint/grit mixture was absolutely vital.

Twenty-four hours passed before heavy, late summer rain rolled in. By then, the paint had cured hard, and the coachroof was finished. They then repeated the whole operation to paint the deck. Nobody said rejuvenating a classic-plastic yacht would be quick or easy. But when the entire project was finished and Lunacy ‘s deck sparkled, the two sailors realized that all their meticulous efforts had been well worth it.

Steps:** 1. In preparation for the job, much of the deck hardware, including the stanchions, had to be removed. The remaining gear was carefully and completely covered and masked. 2. All the fastener holes were filled with silicon sealant, and the couple spent days grinding the old surfaces. Then Janet used a solvent wash to ensure a strong bond with the primer paint. 3. After dings and cracks were repaired and sanded, two coats of epoxy primer were applied. 4. Following another round of sanding, vacuuming, cleaning, and taping, the couple rolled and brushed on a fresh coat of Awlgrip topcoat. 5. After four coats of Awlgrip, it was time for the nonskid. First, Steve experimented with colors and grits. Once under way, he poured on a dollop of pre-mixed paint and spread it evenly. Note the paint stirrer, which was used to prevent the grit from settling. 6. Stirring frequently, to make sure the coverage was even in each masked area, Steve worked quickly and efficiently while Janet addressed small splashes with a solvent-soaked cloth. 7. Voilà! Once the masking tape was removed, the fresh decks fairly glistened.

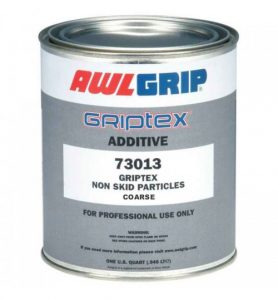

What You’ll Need: • Hook-and-loop sanding discs, sized to fit the sander pads • Sheets of sandpaper of grits 80, 100, 120, 180, 220, and 320 • 3M masking tape in widths of 1/2 inch (No. 256), 1 inch (No. 2090), and 2 inches (No. 225) • Gerson synthetic tack cloths • Roller frames and roller covers, with phenolic cores: ultra-smooth, high-density 4-inch and 6-inch roller covers (available from Home Depot; for the primers and topcoats) and Yellow stripe 3/8-inch nap (from West Marine; for the nonskid paint mixture) • Good-quality varnishing brushes • Cabisil (colloidal silica) thickening agent for making fairing putty with epoxy or polyester resin • Plastic putty knives • Interlux Fiberglass Solvent Wash 202 (for cleaning surfaces) • M.E.K. solvent (for cleaning all brushes) • Disposable paper/plastic pails of various sizes • A dozen wooden paint stirrers • Interlux Epoxy Primekote • Awlgrip topcoat (with Brushing Reducer and brushing converter) • Awlgrip Griptex nonskid additive (fine and coarse grades) • Ryobi and Makita random orbital sanders • Ryobi 6-inch palm polisher (used with a foam pad as a sander in complex spaces) • 3M breathing dust masks, ear protection, and solvent-resistant gloves

Longtime CW contributor Tom Zydler and his wife, Nancy, plan on spending this summer exploring the coast of Labrador aboard their Mason 44, Frances B .

- More: boat maintenance , How To , maintenance

- More How To

Grease the Wheels of Your Boat: A Guide to Proper Lubrication

A Bowsprit Reborn: A DIY Renovation Story

Rigging Redo: Our Switch to Synthetic

Top Tools for Sailboat Cruising: Must-Have Gear for 2024

Galápagos: A Paradise Worth the Paperwork

Around Alone

- Digital Edition

- Customer Service

- Privacy Policy

- Terms of Use

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

Boating Basics Online is reader-supported. When you buy via our links, we may earn a commission at no cost to you. Learn more

The Best Boat Deck Paints for Non-skid, Fiberglass & Wooden Deck

Written by J. Harvey / Fact checked by S. Numbers

No thanks to harsh elements like wind, rains, and extreme heat and cold, any boat is bound to show signs of wear and tear over time. Nowhere is this depreciation more obvious than in the paint coatings on our vessel, on the decks we regularly trudge. What’s good is that there’s always a remedy for a beaten up deck that’s becoming unsightly and deteriorating. There’s nothing that the best boat deck paint can’t polish up in no time. The icing on the cake is that these coats do more than beautify a boat. Some naturally impart non-skid perks that would make any Navy sailor green with envy. Others add years to your boat’s life by making it waterproof and dustproof. A few marine deck paints can even deliver all these things altogether, as proven by this review and buying guide.

- Decent traction

- Good self-leveling

- Outstanding protection

- Very easy to apply

- Decent drying time

- High-gloss and marine-grade

- Notably durable

- Excellent non-skid

- No undesirable odor

Table of Contents

1. Rust-Oleum 206999 Marine Topside Paint

2. totalboat wet edge marine topside paint, 3. totalboat totaltread non-skid deck paint, 4. kiwigrip kg10171r non-skid coating, 5. rust-oleum 207009 marine anti-slip additive, 6. durabak 18 textured non-slip coating, 7. kilz l394811 over armor smooth, 8. liquid rubber smooth polyurethane coating, 9. tuff coat ut-100 non-skid coating, 10. kilz over armor textured, 11. insl-x su031009a-01 sure step coating, 12. evercoat 853 skid-no-more rubberized coating, factors to consider when choosing boat deck paint, what is the best boat deck paint, how should i prepare my boat before painting, how do you paint a fiberglass boat deck, is anti-slip decking paint any good, best boat deck paint reviews.

- Excellent durability

- Strong smell

- Very easy to apply and manage

- Decent drying time and durability

- Doesn’t need a primer if a solid layer of paint is present

- Recommends xylene as thinner

- Limited availability

- Easy to use

- Smoother finish

- Proven durability

- Great traction

- Takes a while to dry

- A little expensive

- Comes with a roller for optimal application every time

- Relatively small amount of paint in every container

- Excellent slip resistance

- Easy to use with most paints

- Adds an extra layer of protection to boats

- Delivers great results even with minimal amounts

- A bit costly

- Delivers way more than what it promises

- Adaptable to most deck surfaces

- Ready to use and easy to apply

- Multiple attractive color options

- Very durable

- Budget-friendly

- Attractive finish

- Long-lasting coats

- Superior coverage

- Not that slip-resistant

- Needs to be thinned well

- Comes in many attractive colors

- Above-average durability

- Easy to prep and use

- Well worth the money

- Costs a lot per gallon

- Superb durability

- Great-looking finish

- Superb color options

- Easy to clean

- Non-hazardous to health and environment

- More expensive than most

- Excellent traction

- Satisfactory durability

- Feels smooth

- Performs well with one coat

- Quick-drying

- More costly than the Smooth version

- More difficult to apply than other paints

- Excellent coverage

- Amazing traction

- Lasts for a long time

- A bit expensive

- Strong odor

- Versatile on most surfaces

- Strong adhesion

- Great value for money

- Quite difficult to manage

- Unattractive colors

- Slip Resistance and Water Protection

The safest choice is always a paint that offers anti-slip because you need to be confident that you won’t slip or fall regardless of how much your deck gets wet. Not all anti-slip paints and additives are slip-resistant and vice versa. However, getting any of the two would always be a good step in the right direction. Waterproof paint not only tends to stay on longer but is easier to clean, too.

Paints that are UV resistant can resist most weather conditions and can handle the pressure of regular foot traffic and abrasions are what you should aim for if you want coats to last. Epoxy boat floor paint tends to be a safe option for this, but as my list above proves, you should also give other kinds of paint a try, even water-based ones.

- Color and Aesthetics

Your boat’s deck is often the one area of your vessel where you can flaunt your style. The colors you choose can either make or break that factor for you. If you want coatings that can hide the dirt and grime, then I suggest you choose darker ones. As much as possible, don’t let the color for boat decks depart too much from its overall theme.

Oftentimes, the paint products themselves would give you detailed instructions about how to prepare your boat to achieve optimal results. In most cases, I’ve discovered that it’s best to stick to these instructions. Otherwise, it’s always best to sand surfaces prior to application, especially if you’re doing a repaint and have to remove flaky stains and coats. It’s standard practice to make sure the surface is spick-and-span clean before you apply any paint product on it.

Besides a few unique steps you need to take, it’s not that much different from painting wood or metal surfaces actually. Make sure you keep the fiberglass clean and dry before applying any kind of paint. Let it dry in a place where it won’t be subject to further moisture or dirt. An important step you shouldn’t forget is to mask off the area you intend to paint. You can use a suitable painter’s tape for this to make sure the final finish won’t have irregular co. Paint for fiberglass boat decks usually requires a primer, but not always. Only use it if the specific paint product calls for it. With the area dried and masked off, you can now begin painting. After you’re done, you can now remove the tape and from there, it’s a waiting game till the coat you applied dries completely.

Yes, there’s no shortage of paints and additives that give the traction you want in your deck surfaces. However, not all of them last long and may need regular application over time. Some are so easy to apply that you won’t mind rolling a fresh layer should the previous coatings begin losing their grip. https://youtu.be/CFi3KRFSw_Y

The best boat deck paint can give you that much-needed Zen-like peace when out boating, fishing, or cruising. Why? Because you won’t have to worry about slips, falls, and a worn-out deck once you apply it. The products I’ve highlighted here can, more or less, help you attain that as long as you pinpoint the best ones for your purposes.

“I am James Harvey – founder of Boating Basics Online. It is established with the drive to help out first-time boaters, which are those desiring to explore their way through the water. So if you are new to boating, start from here with me. “

ACTIVE STORM TRACKER Hurricane and Tropical Storm Information Learn more

Service Locator

- Angler Endorsement

- Boat Towing Coverage

- Mechanical Breakdown

- Insurance Requirements in Mexico

- Agreed Hull Value

- Actual Cash Value

- Liability Only

- Insurance Payment Options

- Claims Information

- Towing Service Agreement

- Membership Plans

- Boat Show Tickets

- BoatUS Boats For Sale

- Membership Payment Options

- Consumer Affairs

- Boat Documentation Requirements

- Installation Instructions

- Shipping & Handling Information

- Contact Boat Lettering

- End User Agreement

- Frequently Asked Questions

- Vessel Documentation

- BoatUS Foundation

- Government Affairs

- Powercruisers

- Buying & Selling Advice

- Maintenance

- Tow Vehicles

- Make & Create

- Makeovers & Refitting

- Accessories

- Electronics

- Skills, Tips, Tools

- Spring Preparation

- Winterization

- Boaters’ Rights

- Environment & Clean Water

- Boat Safety

- Navigational Hazards

- Personal Safety

- Batteries & Onboard Power

- Motors, Engines, Propulsion

- Books & Movies

- Cockpit Confessions

- Communication & Etiquette

- Contests & Sweepstakes

- Colleges & Tech Schools

- Food, Drink, Entertainment

- New To Boating

- Travel & Destinations

- Watersports

- Anchors & Anchoring

- Boat Handling

- ← How-To DIY

Deck Painting Tips

Advertisement

Here are two ways that you can make your deck a lot less slippery — a smart safety idea for all boaters, young and old.

The stripped old-style J/24 deck before we changed and repainted it. The deck (left) shows the final version after repainting.

Fiberglass is slippery when wet. But you know that, you've slipped on the deck of your boat a number of times. You meant to put nonslip tape on the worst spots, but you never got around to it. So what are your options?

Step 1: Buy 3M Slip-Resistant tape and glue it down. The problem with this approach is that the tape only comes in a few colors and stands out on the boat's deck. It will also collect dirt around the edges, and if it's not properly installed, the edges will lift.

Step 2: Use a pre-mixed product such as Interlux's Interdeck or Pettit's EZ-Decks to create a nonslip area. This is fine except that you might not be able to match the color of your deck exactly and may have to recoat the entire deck. In addition, you might need more grip than Interdeck provides. I've found that a deck coated with Intergrip nonslip particles lasts about three to six years (depending on use) before it needs recoating.

Step 3: Take a DIY approach and use a topside paint to match your boat paint exactly and add enough nonslip particles to be sure that you have exactly the right amount of grip without creating sandpaper that will do a job on your knees and behind. I've found that this method lasts longer than Interdeck or EZ-Decks.

Changes to the deck included fitting a new sliding companionway hatch and sea-hood, a Lewmar forehatch, and repairing rotted balsa core. After repainting, the finished job is shown above right, with some of the deck gear installed.

Painting Interdeck

Painting Interdeck is easy. To get started:

Step 1: Mask off the area to be painted. If desired, you can sand it to give the paint a better grip. Use 220- to 300-grit sandpaper.

Step 2: Wipe down with solvent to remove grease and dirt. For Interdeck, use 2333N solvent.

Step 3: Open the can and mix the paint well. If you wish to make the deck more nonslip, you can sprinkle Interlux's InterGrip onto the wet-paint layer or add it to the can of paint. InterGrip is a polymeric (it contains tiny plastic spheres) nonskid additive available from most chandleries.

Step 4: Roll the paint onto the area to be painted. Use a high-nap roller that can withstand marine paint. If you sprinkle the paint with Intergrip instead of mixing it into the paint, you'll need to cover the area with a second layer of paint.

Step 5: Wait until the paint is almost set up, then peel off the masking tape. Be sure to lift the tape clear of the deck as you peel it; there may be a little wet paint on the tape, and you need to keep it off the deck. Job done!

Step 6: Allow 24 to 48 hours before walking on deck.

Round all the corners using a small paint can or a coin to ensure that the finished job looks professional.

Get It Right

You can color match and make a longer lasting nonskid surface by doing the job slightly differently.

Step 1: Follow steps 1 and 2 above.

Step 2: Set up your paint. You can use Interlux's Brightside enamel (one-part), Perfection, Awlgrip topside paint (both two-part paints), Pettit's topside Yacht Enamel (one-part) or any of the other topside paints. Mix a flattener into the paint. A flattener will take the gloss off the paint, which is advisable because the sun can reflect off a high-gloss deck and make it difficult to see.

Step 3: Roll the paint onto the deck using a high-nap roller.

Step 4: While the paint is still wet, sprinkle it with Interlux's Intergrip or any other microsphere product. (You can use sand, but it will do what sandpaper does to clothes, knees, and shoes, plus the sand particles will eventually work their way out of the paint layer. You can also use crushed walnut shells, but they add a brownish cast to the paint and can be even harder on you and your clothes than sand.) To sprinkle the powder, make a few 1/8-inch holes in the top of the can with a metal fid or marlinspike. Hold the can about 18 to 30 inches above the surface and sprinkle away. No wind is a must when you do this or you'll find most of the Intergrip alongside the boat.

Step 5: Let the paint and Intergrip dry thoroughly. Now roll on another layer of flattened (non-glossy) paint over the nonskid area. This seals in the microspheres and makes the final layer look nice.

Step 6: Let the paint dry until it is almost set, then carefully peel off the masking tape.

Step 7: Allow 24 to 48 hours for the paint to set up hard before walking on it.

How To Install Nonslip Tape Where You Need It

Nonslip tape is usually installed over slippery areas such as on hatches, where it provides grip without blocking too much light. You can also install it on the edge of stairs, any sloping surface, and other areas where the danger of slipping is present.

Step 1: Make sure the area to be covered is clean. Use a proprietary cleaner recommended by the manufacturer to clean the clear part of any hatches. Don't use acetone, which might discolor hatch glazing.

Step 2: Decide where you want to put the tape. Use a grease pencil to mark off areas. Cut tape to length and use a coin to make quarter-circles at each corner. Trim corners around the quarter-circle to prevent them from lifting later.

Step 3: Peel the backing off the tape and press it onto the area to be covered. Press the tape down firmly (stand on it!) to make sure it adheres properly. That's it, you're finished!

Related Articles

The truth about ceramic coatings for boats.

Our editor investigates the marketing claims of consumer-grade ceramic coatings.

Fine-Tune Your Side Scan Fishfinder

Take your side-scanning fishfinder off auto mode, and you’ll be spotting your prey from afar in no time

DIY Boat Foam Decking

Closed-cell foam flooring helps make boating more comfortable. Here’s how to install it on your vessel

Click to explore related articles

Roger Marshall

Contributor, BoatUS Magazine

Roger Marshall is a writer and yacht designer who lives in Rhode Island.

BoatUS Magazine Is A Benefit Of BoatUS Membership

Membership Benefits Include:

Subscription to the print version of BoatUS Magazine

4% back on purchases from West Marine stores or online at WestMarine.com

Discounts on fuel, transient slips, repairs and more at over 1,200 businesses

Deals on cruises, charters, car rentals, hotel stays and more…

All for only $25/year!

We use cookies to enhance your visit to our website and to improve your experience. By continuing to use our website, you’re agreeing to our cookie policy.

6 Best Boat Deck Paint – (Reviews & Buying Guide 2021)

Ah, imagine if the pirate ships a few centuries ago were able to paint their decks in various colors. Boating wouldn’t have been so gloomy, right? Luckily, today we can put whatever nuance we want on the floor of our boat, but to do so, we need to obtain the best boat deck paint available.

So here, we are giving you this extensive guide on how to purchase the right product but also how to carry out your deck painting project. Before you get to our tips, make sure you check out the reviews of boat deck paint that we have compiled because your project will be doomed without the most suitable paint for your needs.

Best Boat Deck Paint Comparison Chart

| PRODUCT | DETAILS | ||

|---|---|---|---|

TotalBoat Non-Skid Deck Paint | |||

Rust-Oleum Anti-Slip Additive | |||

Liquid Rubber Deck Sealant | |||

Kiwi Grip Non-Skid Deck System | |||

Rubberseal Liquid Rubber Coating | |||

Interlux Slip Resistant Deck Paint |

Best Boat Deck Paints (New List 2021)

So, check out the paints that we have selected, but don’t assume that No. 1 may automatically be the best one.

1. TotalBoat Non-Skid Deck Paint

The finish won’t get scratched or wear away if you scrub it. Apart from applying this product on your boat deck, you can use it for stairs, docks, swim platforms, floors, and everywhere else you need secure foothold.

One galloon will be enough to cover 250 to 300 square feet. Keep in mind that it is advisable to apply two coatings to make the traction more efficient. You can use either a brush or a roller to put this paint on wood, fiberglass, or painted surfaces.

The product comes in four colors, which are suitable for boat decks.

- An advantage of this product is that it withstands not only the weather conditions but also scrubbing and cleaning.

- Since this paint is less abrasive than sand impregnated coatings, it is easier to sweep off.

- This deck paint is easy to apply and adheres well if the surface has been adequately prepared beforehand.

- You can cover around 300 square feet with one galloon, which is more than what similar products offer.

- The time needed for the paint to fully solidify is pretty long. It may take from 2 to 3 weeks, depending on the air humidity.

- As it has an oil base and it is pretty thick, the paint cannot be applied by spray gun unless you thin it.

2. Rust-Oleum Anti-Slip Additive

To understand the effect of this anti-slip better, you can imagine that you add fine white sand to the latex or paint. The texture of this product resembles pumice, which is the reason it makes the surfaces covered with it non-skid. You can be assured that the anti-slip features of this material will be active as long as the coating exists.

If you intend to apply the mixture of paint and this additive on waxed materials, you have to remove the wax first. Make sure that you have prepared the surface well, and it is clean and dry.

- Being mixed with paint or latex, this additive is easy to apply.

- This substance has proved to be durable – its anti-slip effect lasts as long as the coating does.

- The Rust-Oleum additive doesn’t change the color of the paint.

- You can put this product on floors to make sure that they are not slippery because it makes the surface it covers anti-skid

- If you add this additive to top coating, its grains may capture grime, which will make your deck look dirty.

- The surface covered with the mixture of paint and this anti-slip appears to be rough on bare feet.

3. Liquid Rubber Deck Sealant

There is no need to mix the paint with any other substances, and you can apply it by roller, sprayer, or brush. Thanks to its liquid rubber polyurethane formula, this coating makes the surface it covers resistant to water and UV rays.

The area that one gallon can cover is approximately 100 square feet. The manufacturers recommend applying from 2 to 4 coats, especially if the surface is waterproof. Keep in mind that due to the time required for the paint to dry, you cannot apply more than two coats per day.

Depending on how the coating is treated and on the weather conditions, its life expectancy can be from 5 to 10 years. Before applying the sealant, make sure that the surface is clean and dry.

- This product comes in a variety of colors.

- You will be surprised how easy it is to apply this sealant.

- Thanks to the liquid rubber it is made of, this coating bonds very well to the surface.

- Unlike similar products, this one dries quickly.

- You are not advised to apply this paint if the weather is too hot.

4. Kiwi Grip Non-Skid Deck System

The second reason is that it is very convenient to apply this coating using the KiwiGrip roller. Not only will you cover the surface with this tool with only one coat, but there won’t be any need for additional fillers. What is more, there won’t be any traces of shells, rubber particles, or sand on the covered surface.

The third reason which makes this product worthy is the fact that it is eco-friendly because it is water-based. This coating comes in 5 colors you can choose from.

- The product comes with a KiwiGrip 4-inch roller.

- You can save money using this material, as you will need only one coat of it.

- Its water base makes the Kiwi Grip eco-friendly.

- This substance makes the surface it covers anti-skid.

- As the KiwiGrip is not a sealed paint, you will have to prime any aluminum surface before you put the coating.

- If you want to have the non-skid effect that this product offers, you have to apply it only using the KiwiGri roller, which is a limitation as some people may prefer brushes or sprayers.

5. Rubberseal Liquid Rubber Coating

here are four colors you can choose from. If you need another color which is not offered, you can use elastomeric paint. Keep in mind that it is advisable to apply two coats of the rubber seal. Make sure that the surface is clean of dirt or residue and dry before you put the coating.

An advantage of this product is that it features elongation, which means that it will expand and contract with the expansion and contraction of the material it covers. Even though this coating has a slight odor, it is not unbearable. Since this rubber seal is water-based, it won’t bond to wood or any oil-based surfaces.

- This product has an EPA star rate, and it is resistant to UV exposure.

- You can easily apply the coating by roller, brush, or sprayer.

- Being pretty thick, this material adheres well to the surface and protects it from water.

- The manufacturer offers four colors of this coating.

- It takes around five days for the coat to be ready, and you need to make sure the weather is hot during this period.

6. Interlux Slip Resistant Deck Paint

Bear in mind that it is recommended to apply two coats of the paint for better results. Interlux is one of the manufacturers who offer very handy to use non-skid paints. The easiest way to do it is by roller. A disadvantage of this product is that the lighter colors get dirty quickly, and the dirt is hard to come out. This effect is caused by the small grains that the paint consists of, which gather grime.

- This Interlux paint is easy to apply and provides a good grip.

- You can walk safely on a floor covered with this material as it is non-slippery, but at the same time, it is not rough on your bare feet.

- Interlux offers four colors you can choose from.

- The paint doesn’t reflect the sunlight glare.

- The white paint gets dirty quickly because of the little grains that gather the dirt.

Importance of Having a Non-Skid Boat Deck

So how do we achieve that effect, and can it be a DIY project? It absolutely can be, and there are two main ways to have a non-skid deck.

- Use a can of designated non-skid paint

- Mix a non-skid additive with your color.

The latter will require you to purchase two materials while the former will allow you to deal with the whole project just by using a can of paint. Both options are worth exploring because we simply have to be aware of all the benefits of non-skid deck applications .

When we talk about the boat deck, the surface you are painting will likely be wood or fiberglass. Some people also go for rubber boat flooring.

The hull of the boat may be made of aluminum but definitely not the deck. Still, the body will also require painting, so you might as well jump to our reviews of the top paints for aluminum boats and see if you like our picks.

How to Paint my Fiberglass Boat Deck?

- Select the right paint

This is why we have compiled the reviews and the top list above. We suggest you pick one of the selections and go with it. If you go with a topcoat paint, you will also need to get an additive. The two-part polyurethane products eliminate the need to do so.

We will follow the steps of painting a deck using either of the options. Only towards the end, the stages differ from one another. There is also a third option which we will not outline – purchasing a paint which has been pre-mixed with some powders. We don’t have such a product on our list because we don’t think the quality is exceptional.

- Preparation

This is an essential part of your project. Ys, many people suggest that the actual application of the paint matters because inexperienced people can make it look ugly. While this is correct, experienced pros will also achieve poor results if they work on a poorly prepared surfaced.

Do you know what Marcus Aurelius said? The secret to all victory lies in the organization of the non-obvious. This is why we will devote a little bit more time to this stage of the project and will list some of the things you have to pay attention to.

- Start by deciding where you will conduct the whole paint job. We don’t suggest you do it outside. It is best if the boat can be indoors and even out of the water. Some vessels can have the panels of the deck removed. This will allow you to paint piece by piece and then have them installed back. In any way, find a shelter that is large enough and has sufficient amounts of airflow.

- Don’t paint early in the morning or late in the evening. We recommend you do that before noon because this is the optimal time for any paint to cure. During the evening, the moisture levels will rise and will slow down the process of drying.

- We at The Marine Mag know how to take care of a boat. Check out our boat detailing page for more info. Until then, remember that if you prepare things correctly, you will have less work after you finish painting. Masking is an integral part of the procedure, and you must be very careful with it. Make sure you do not leave any air under the tape and also be careful to create straight lines. We suggest not to don’t rush it.

- Become familiar with the instructions. Diluting your paint or not using the correct amount can result in disastrous outcomes. Don’t underestimate the information on the can. After all, the manufacturer will know best exactly how to mix the paint. They’ve conducted the tests for you.

We got a couple of tips related to sanding as well. This is also a crucial stage because if not done correctly, you will notice that the paint may look different in some areas. The good thing is that once you paint using a non-skid paint, you won’t need to sand for any subsequent paint project on that surface.

But if that’s the first time you are painting the deck, then roll back your sleeves and get to work. We recommend using an automatic sander. The ones that rotate in random directions are the best. No need to push hard – let the machine do the work. You can also use a palm sander, but such an item will be good for the edges or some hard-to-reach spots.

This is another tool on which you don’t want to go cheap. Use it generously because once the sander wears off, it’s really no good. Applying a new brand-new sander is always very useful, so once you feel like the paper is thinning, change it.

- Clean before you paint

After all the sanding and masking, you will surely see plenty of dust on the deck. Never neglect cleaning the area before you whip out the can of paint. Make sure you sweep or vacuum every little piece of dust because the filthy surface is impossible to paint, and your project will be a grandiose failure.

This is where we suggest you check out our pro reviews of the top boat cleaning brushes . You cannot own a boat without having a brush around. See the most popular products and pick one.

Applying the Paint on the Deck

And now we get to the meat of things. This is where the situation changes a little bit because you may have opted for a paint that has its own non-skid properties. Your other options are the classic one, where you will have to mix the paint with an additive. So let’s begin with that choice and outline the process of using a powder.

Using a non-skid additive with your boat deck paint

The exciting thing here is that this subsection is divided into even more possible choices and steps. They are all related to how you want to have the paint, and the additive mixed. You got three main choices.

- Paint the surface using your regular coat and then use a strainer to distribute the powder on the surface. You will have to wait for the paint to cure a little bit and then blow the powder that hasn’t stuck away. Then, apply the second coat and seal the powder between the two layers of paint.

- Your second option is to simply use your hand and spread the additive over the paint. This is similar to what you do when you season your food. You just have to be careful to distribute the material evenly.

- The trickiest option is to mix the additive and the paint before application. This will yield the best results, but it can also turn into a catastrophe. You must be sure you are aware of the proportions because otherwise you risk using too much or too little powder. In the first case, applying the mixture will be a nightmare as your roller or brush will likely get clogged with the additive. In the second case, you will barely achieve any non-skid effect.

Using a two-part paint where extra material is not required

Some paints (even on our list) do not require the use of powder to create non-skid substance. This is quite the advantage, and the whole project may turn out to be a simpler one.

- Use a brush and start applying the paint at a shallow angle. Put down as thick of a layer of paint as possible.

- This paint should come with a unique roller with an advanced grip. This is not your typical foam roller but a curly one, which is used only to create the texture. It is essential to remember that part. You don’t use the roller to distribute pain but only to texturize it. Go over the surface a few times and in different directions so that you can achieve a uniformed pattern.

- Wait for it to cure and remove the tape. You’re done!

This is where we will say “goodbye” only to hope to see you again in one of our other guides. The Marine Mag team is sure to have helped you in your search for the best boat deck paint . If you have any doubts regarding a specific product, by all means, read or reviews of boat deck paint once more.

Tell your friends and family about us and leave us a comment. Your feedback is much appreciated, and it makes us always move in the right direction. Thanks for reading!

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

Better Sailing

Best Non Skid Boat Deck Paints

Painting your boat’s deck can be a challenging task. In this article, we will take a look at the Best Non-Skid Deck Paint for your boat or sailboat. For this article, I asked some boaters friends of mine, marine product professionals, and some online forum buddies of mine and well as my personal experiences with some of the following products.

A good non-skid boat deck paint provides a slip-resistant surface on your boat that is essential when you try to move on your deck even at the best of conditions. In foul weather, a non-skid coat of paint could be the difference between life and death. These anti-slip paints will increase friction and reduce the likelihood of a fall overboard.

Kiwi Grip Non-Skid Deck Paint – Overall The Best Non-Skid Boat Deck Paint

If you’re DIYing it. Go with Kiwi Grip . It’s overall the best non-skid deck paint for your boat, and as long as you plan well, you can do a whole boat, including the cockpit, in about three sessions. But be warned, it’s expensive stuff. It costs around 150$ per gallon (4 Liters), and each gallon can of KiwiGrip can cover about 80 square feet.

I like the Kiwi Grip because it’s water-based, so easy to clean up and deal with. For the non-skid effect, you just use a special roller, no sand or crushed shell or whatever people add for the non-skid effect, which makes for an easy application. It probably the easiest material to work with to give your boat the desired non-skid effect.

It is a good idea to experiment on a piece of plywood before tackling your deck. Kiwi Grip is easy to mess up like just about anything! Practice makes almost perfect! But do not worry, even a bad Kiwi Grip job still works great; making it look pretty is about finesse and practice. A Blue Paper Masking Tape will be your best friend in this application, so you can make the edges perfect.

I had very good results with Kiwi Grip; follow directions carefully, don’t let it freeze, and practice, for the best possible results, apply the paint on a dry and hot day. Remember, you can always go over any part that isn’t perfect again. And last but not least, do not forget to wear a mask.

- Easy To Apply

- Great Non-Skid Effect

- Doesn’t look as good as some other options if not done carefully

TUFF Coat Non-Skid Coating

This type of paint is becoming very popular lately, and for a good reason, TUFF Coat is easy on your feet, highly durable, and has the added benefit of looking good as well. A friend of mine has used it for about 10 years now on his catamaran sailboat. He recoated once, 4 years ago, and is very happy with it. The two-part primer they have for it is very runny, so be careful with it. It sticks to itself great, though. It stretches a bit, which can hide minor Gelcoat cracking, and is very soft on the knees and bare feet because of the rubber particles.

For proper application, use a drill mixer to thoroughly stir and suspend all the rubber non-skid particles into the paint. Then, pour the coating into a paint tray and load your roller with enough paint. For maximum non-skid effect, you can use a paint roll similar to the one that is used for the Kiwi Grip application. That way, you will get the benefits of both the texture and the non-skid particles.

You will need around 1 Gallon of this stuff to cover 150 square feet of deck surface; per coat, 2 necessary, 3 recommended.

- Easy to apply

- Many colors

TotalBoat TotalTread Non-Skid Deck Paint

This is another single part nonskid paint for your deck, so you do not need to mix anything yourself. Just remember to stir very thoroughly before applying to ensure the solvents and non-skid particles are mixed in evenly, preferably with a paint mixer . This paint gives a flat finish with a non-slip texture, so if you do not like the texture that Kiwi Grip has, this is probably the way to go. It comes in 3 colors white, gray, and sand beige. To get a good result, you will need about two coats of paint, but if you decide that the desired effect is not there yet, you can add an extra coat for a more slip-resistant surface.

Before applying, make sure you clean the fiberglass properly with plenty of water and soap (let it dry) or prime first with TotalBoat Topside Primer. You can use both a brush or roller, but I would recommend rollers to get a more even result.

This product is very user friendly since the application is as straight forward as painting a wall at your home. As a pro tip, it is better to apply multiple thinner coats of paint instead of one or two thicker ones. Also, give the paint one or two days to dry before you apply another coat, depending on temperature and humidity.

Keep in mind that you will need around 1 Gallon of this stuff to cover 250 square feet of deck surface.

- Not very durable

- Doesn’t dry easily in humid and colder climates

Interlux Interdeck Slip Resistant Deck Paint

This is a one-part polyurethane paint with the non-skid particles already mixed in; just remember to shake the solution well before applying to make sure all the solvents and non-skid particles are mixed in evenly. Also, while you are applying the paint, keep stirring it often because the non-skid will settle down to the bottom of the container. Interdeck has a nice matt finish to reduce sun glare. It may be applied over any type of paint, but you should not apply it over clear epoxy. Clear epoxies must be primed with Epoxy Primekote 404/414 before applying. Make sure to go through and follow directions carefully to make sure you properly prepare and apply the paint. Also, make sure to put tape over the areas you do not want to apply the non-skid paint to get the best looking deck.

Awlgrip TopCoat With Griptex Non-Skid Additive

This what the professionals recommend when it comes to non-skid deck paints. However, you will have to use Awlgrip TopCoat and also use their Griptex additive. You mix the two products together, preferably with an Electric Paint Mixer , and then the solution can be rolled on.

My boat had previously painted with Awlgrip TopCoat With Griptex Non-Skid Additive. The boatyard this winter sanded it, primed, applied two coats of paint with rollers, then they sprinkled the Griptex with a salt shaker-type when the paint was still wet, vacuumed the loose Griptex particles off, and then rolled on two more Awlgrip TopCoat coats on. I found it smart and intuitive instead of mixing more material than you need and wasting it. Awlgrip with Griptex additive will look the best, but its grip is inferior to Kiwi Grip.

AwlGrip White Base With Crusted Walnut Shells

I have to say this is a very controversial way to apply a non-skid coat on your boat. However, a friend of mine has done it, and I have been on this boat, and I must say that the result is great. It feels good on your feet, it has the desirable non-skid effect and is also pretty affordable.

You apply it the same way you would apply the Griptex Non-Skid Additive to your AwlGrip TopCoat. The best way to apply it is to coat a thick layer of AwlGrip on your deck and then sprinkle the Crusted Walnut Shells on the wet paint; make sure to sprinkle the shells evenly. Let it rest overnight, and then vacuum the loose Crusted Walnut Shells off. Then, apply two more coats of Awlgrip TopCoat.

>>Also Read: Best Boat Coatings

Tips For Appling Any Non-Skid Paint On Your Boat

There are two types of people when it comes to preparing your deck for paint application. Many people sand their whole deck, and then they vacuum and clean it. The other ones just use a good deck cleaner and plenty of water to thoroughly degrease and clean the deck. That second way is ok if it is the first time you are applying a non-skid paint on your deck. However, you must remove all chips and peels from the deck’s surface. If you are reapplying, I would recommend removing the old coat first or at least sanding the old coat off as much as possible.

Pick a day that is not overly hot and sunny nor cold and cloudy. You do not want your paint to dry up too quickly nor to stay wet for two days straight. However, make sure to leave the paint cure at least for hours before you apply another coat.

Use a paint mixer drill attachment to stir the paint before each application, especially on two-part non-skid paints. I would recommend this on pretty much all the paints featured in this article, but you can get away without using one on the Kiwi Grip because there are no non-skid particles suspended on that type of paint.

Lastly, you will need a paint set that includes paint rollers, paintbrushes, and a paint tray. Also, get a Blue Paper Masking Tape to help you protect the non-skid areas and help achieve the best possible look.

Final Thoughts

The Best Non-Skid Boat Deck Paints is the Kiwi Grip, hands down; it is easy to apply and will get you the best result. To spruce up your boat’s deck with great functionality, you need to apply a new coat of non-skid paint. You’ll be able to change the color (Kiwi Grip comes in Black, Blue, Cream, Grand, and White) and dress it up while also adding a layer of protection to your deck’s surface. Old, dull fiberglass surfaces like your deck can become fresh and clean in very little time and effort. The Best Non-Skid Boat Deck Paint will also protect fiberglass surfaces from liquids, repel stains, and provide a nonslip surface for safe walking. Also, if your fiberglass has developed chips and spider cracks over the years, a coat of paint will cover them right up and your boat will appear as good as new.

Also, if you are not sure you want to paint your deck them you could consider a Non-Skid Self-Adhesive Foam Teak Marine carper for your boat.

Peter is the editor of Better Sailing. He has sailed for countless hours and has maintained his own boats and sailboats for years. After years of trial and error, he decided to start this website to share the knowledge.

Related Posts

The Ultimate Guide to Choosing the Best Fishing Line for Trolling

Lagoon Catamaran Review: Are Lagoon Catamarans Good?

Best Inboard Boat Engine Brands

Are O’Day Sailboats Good? A Closer Look at a Classic Brand

- Buyer's Guide

- Destinations

- Maintenance

- Sailing Info

Hit enter to search or ESC to close.

- International Marine Coatings

- International Protective Coatings

How do you paint non-skid decks?

Although there is no single, universally proven deck surface that will prevent people from slipping on a boat deck, a low-cost, slip resistant finish gives added protection and can be easily applied. Find out how below.

Interlux now offers three solutions for refinishing a non-skid deck:

- Stir and apply Interdeck – a pre-mixed, slip resistant, single component, ready to use deck paint that can be applied over Prekote primer or Epoxy Primekote primer 404/414.

- Mix your own non-skid finish: any one of the Perfection or Brightside Polyurethane finishes can be transformed into a non-skid deck finish by the addition of Intergrip Polymeric non-skid compound 2398. Intergrip is made from small plastic spheres that have regular shape, low tendency to collect dirt and excellent non-slip properties. Once Intergrip has been added to paint general application directions are followed, except there is no need to sand between coats. Our two part polyurethane, Perfection, provides the most durable and long lasting finish for decks.

- Hand Broad casting method - while the first of paint is still wet, sprinkle the Intergrip as required to obtain the texture of your choice. It is best to put the Intergrip in a flour sifter or salt shaker to dispense the compound. Avoid heavy application which will not assist in providing a more slip resistant surface. After the paint has been allowed to dry overnight remove the excess Intergrip and apply the second coat of paint.

Paint your boat like a pro

Find the best products to keep your boat in great condition

Get all the support you need to paint with confidence

Benefit from our continuous innovation and scientific expertise

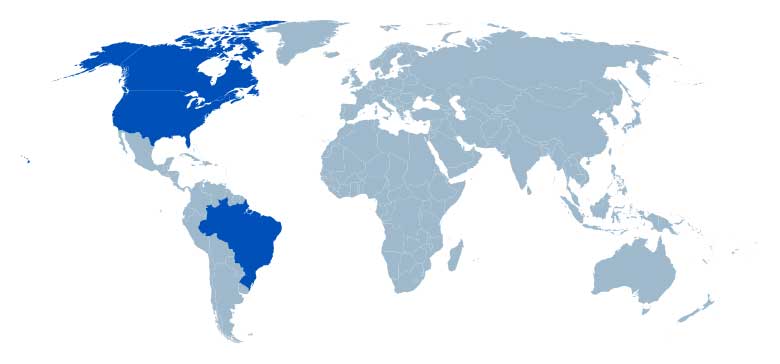

Select your country

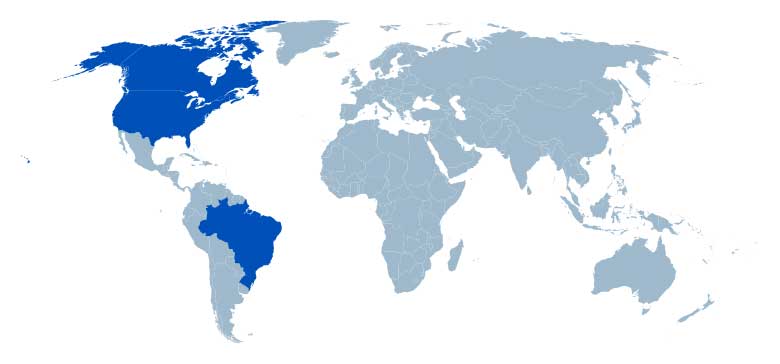

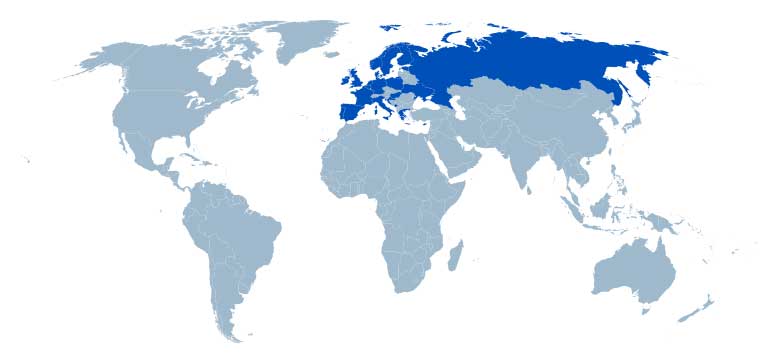

Our products and guidelines are customised for each country. Please select yours below.

- Canada Canada

- United States United States

Asia Pacific

- Australia Australia

- New Zealand New Zealand

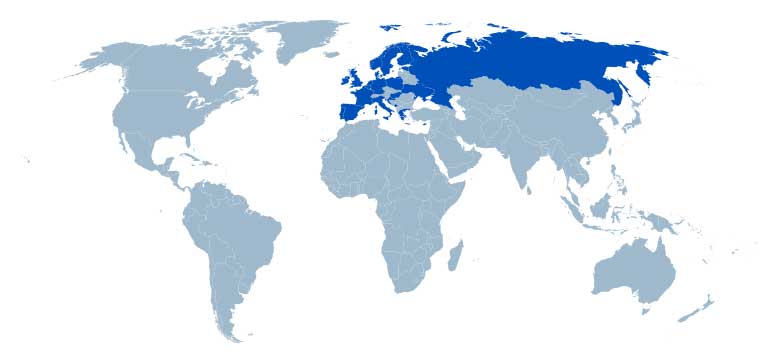

- Singapore Singapore

- België Belgium

- Hrvatska Croatia

- Danmark Denmark

- Suomi Finland

- France France

- Deutschland Germany

- Ελλάδα Greece

- Ireland Ireland

- Italia Italy

- Nederland Netherlands

- Norge Norway

- Portugal Portugal

- España Spain

- Sverige Sweden

- United Kingdom United Kingdom

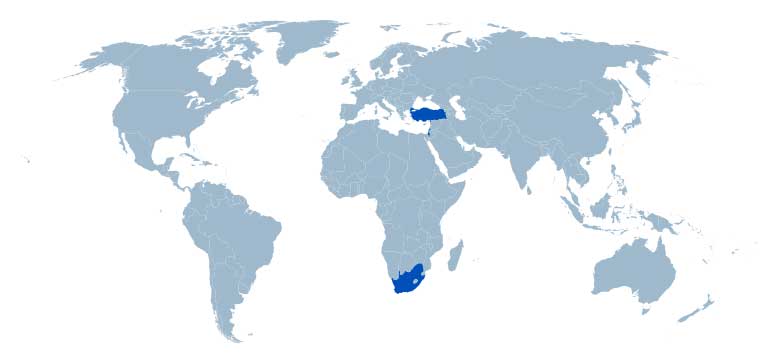

Middle East & Africa

- South Africa South Africa

- Türkiye Turkey

Who's painting?

Choose one of the following to tailor the site to your needs.

- International Marine Coatings

- International Protective Coatings

How do I paint a non-skid deck?

Although there is no single, universally proven deck surface that will prevent people from slipping on a boat deck, a low-cost, slip resistant finish gives added protection and can be easily applied. Find out how below.

First, choose the right paint.

A deck demands a tough coating to protect it from the damaging effects of foot traffic, anchors and other gear that may fall on it. With that in mind, a two part polyurethane paint with a non-skid additive / powder is possibly your best option. You aren’t limited to using a two-part paint though, you can also add such additives to single pack top coat paints. Alternatively, you can use products that are premixed with suitable non-skid aggregates.

How to apply the non-skid additive / powder material

There are various ways of applying the material and it really comes down to how you’d like to tackle the job. Below are our suggestions, but you may have other ideas and it really doesn’t matter as long as you achieve the effect you want.

- The easiest way is to shake the powder onto a layer of wet paint. One way to do this is to take a plastic container and drill many 3 mm holes in the lid and use the container like a large pepper shaker. Shake the powder on until the whole surface is covered by a layer of powder. Allow the paint to semi-cure and then blow the excess powder off the surface and apply a further coat of paint to seal it all down.

- Another way is to stir the powder into the paint and then apply. This method can be a little tricky, as you have to ensure the powder doesn’t bunch up under the roller or brush giving a patchy effect.

- The other method is to hand broadcast the powder on to the surface as if you are sowing grass.

How to produce the non-skid area

- Firstly, make sure the second coat of the topcoat you applied is well cured and that you follow the drying and overcoating times on the topcoat label.

- Mask-off the area in the pattern intended for non-skid. You can use 3M® 218 Fine Line masking tape which goes around curves really well. Or you can use normal masking tape laid down in strips at the corners and then carefully cut it into a curve. Cans and jars of various sizes are useful as templates to create exactly the curve you want.

- Paper mask-off the area you want to protect.

- Lightly roughen the exposed areas with 280 grade paper.

- Apply one coat of topcoat as per label instructions.

- Using one of the methods described above, apply the powder material while the topcoat is still very wet.

- Allow the coat of paint to dry for the appropriate period. Do not exceed the overcoating time.

- Very carefully vacuum or blow away any excess powder.

- Carefully apply a second coat of topcoat taking care to do it without over brushing.

- Allow to dry for a few days before allowing heavy traffic use.

Refurbishing an existing deck

This can be difficult to do, however the easiest way is to sand the existing system back to a smooth finish and re-apply undercoat / topcoat / additive powder. Attempting to clean and prepare the existing surface and then apply new coats of paint may result in the original non-skid finish being partially buried. This could cause adhesion problems with the new system if it’s not prepared properly.

Paint your boat like a pro

Find the best products to keep your boat in great condition

Get all the support you need to paint with confidence

Benefit from our continuous innovation and scientific expertise

Select your country

Our products and guidelines are customised for each country. Please select yours below.

- Canada Canada

- United States United States

Asia Pacific

- Australia Australia

- New Zealand New Zealand

- Singapore Singapore

- België Belgium

- Hrvatska Croatia

- Danmark Denmark

- Suomi Finland

- France France

- Deutschland Germany

- Ελλάδα Greece

- Ireland Ireland

- Italia Italy

- Nederland Netherlands

- Norge Norway

- Portugal Portugal

- España Spain

- Sverige Sweden

- United Kingdom United Kingdom

Middle East & Africa

- South Africa South Africa

- Türkiye Turkey

Who's painting?

Choose one of the following to tailor the site to your needs.

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Blue Jacket 40 Used Boat Review

Catalina 270 vs. The Beneteau First 265 Used Boat Match-Up

Ericson 41 Used Boat Review

Mason 33 Used Boat Review

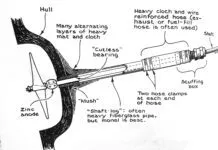

How to Create a Bullet-Proof VHF/SSB Backup

Tips From A First “Sail” on the ICW

Tillerpilot Tips and Safety Cautions

Best Crimpers and Strippers for Fixing Marine Electrical Connectors

Polyester vs. Nylon Rode

Getting the Most Out of Older Sails

How (Not) to Tie Your Boat to a Dock

Stopping Mainsheet Twist

Fuel Lift Pump: Easy DIY Diesel Fuel System Diagnostic and Repair

Ensuring Safe Shorepower

Sinking? Check Your Stuffing Box

What Do You Do With Old Fiberglass Boats?

Boat Repairs for the Technically Illiterate

Boat Maintenance for the Technically Illiterate

Whats the Best Way to Restore Clear Plastic Windows?

Stopping Holding-tank Odors

Giving Bugs the Big Goodbye

Galley Gadgets for the Cruising Sailor

The Rain Catcher’s Guide

Sailing Gear for Kids

What’s the Best Sunscreen?

UV Clothing: Is It Worth the Hype?

Preparing Yourself for Solo Sailing

R. Tucker Thompson Tall Ship Youth Voyage

On Watch: This 60-Year-Old Hinckley Pilot 35 is Also a Working…

On Watch: America’s Cup

On Watch: All Eyes on Europe Sail Racing

Dear Readers

- Inside Practical Sailor

Refinishing Your Boat’s Non-skid Deck

While the consequence of letting your varnish and hull paint to fade is usually no worse than a blow to your ego, you don’t want to let your non-skid deck paint lose its grip. More than a few cruises have been cut short because someone lost their footing on a slippery deck.

Refinishing your boat decks nonskid coating is a big project, but so are the payoffs. Not only does it make your deck look like new, it is a whole lot safer. Here some general tips to help you get more mileage out of a nonskid restoration. For additional research, I’ve posted links to our previous tests of non-skid deck products.

Proper Application

The secret to durable non-skid starts with proper application.

Surface prep: We all know proper surface prep can make or break coatings applications, but it also directly affects the coatings service life. Always follow makers recommendations.

To prime or not to prime? That depends on the deck substrate being painted and the type of paint being used. If the surface is bare wood or bare metal, plan to apply a coat of primer (and a sealer for wood). A one-part primer is often sufficient, but a two-part epoxy primer will offer more durability and hardness. If you are allergic to epoxy, there are some excellent polyurethane primers designed for cars that also have good track records in the marine environment ( PS is currently researching this further and would be interested in hearing from readers who have gone this route). Bare fiberglass requires a dewaxer, scuff sanding, and a coat of primer when applying most paints; however, some paints like Durabak and KiwiGrip recommend primers only for bare metal and wood.

Application: The surface must be clean and totally dry. After sanding, wipe it down with xylene, dewaxer, or acetone. Some paint makers warn against using solvents, so be sure whatever you wipe down with is compatible with the paint. The easiest paints to apply are those one-part paints that have the additive already mixed in. As long as the paint is thoroughly mixed, you can achieve a relatively even finish (see the cardboard trick described below for two-part paints).

When it comes to using a paint with a separate nonskid additive, we recommend combining the mix-in and broadcast methods to get the most uniform grit pattern. Mix the nonskid additive with the paint, roll it on with the recommended nap roller (usually 1/4″ – 3/8″ solvent resistant), and sift more aggregate on the paint while its tacky; once the paint dries, you can brush off the excess and apply a second coat in the same manner. You can make an aggregate shaker by poking a dozen or so holes in the lid of the can with an ice pick, then up-ending it to sprinkle the additive across the deck. Pre-mixed nonskid paint users can also broadcast nonskid additive atop coats of the pre-mixed paint for a more aggressive grip.

Two-part LPU paints like Awlgrip will generally last longer and stay cleaner than textured paints or one-part coatings, but these temperature and humidity-sensitive products can be more difficult to apply for a first-timer. If you are rolling, the makers generally recommend that the additive be sprinkled or sprayed on while the paint is still tacky to achieve an even covering. The excess additive is brushed and vacuumed away and then the surface is recoated with paint (no additive). Following the maker’s guidelines for spray application will generally achieve a more even result.

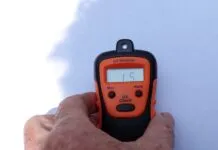

Although the maker of Awlgrip advises that Griptex, the designated texture additive, should not be mixed into paint when rolling paint, we have done this using a technique shared with us by a Florida boatbuilder who has used this on his own boats for years. If you want to go this route, you should do a few test runs.

The main problem with using a roller to apply LPU paint with the non-skid additive mixed is that the texture tends to clump. This problem is exacerbated by the narrow working window for applying with two-part paints. To avoid clumping and wasting paint, you can use a small sausage roller with a medium to fine fiber nap (3/8″-1/8″). Be sure the roller is solvent resistant. Foam roller covers are not recommended. Carefully measure the desired texture before adding it to the pre-mixed paint, and thoroughly stir the additive into the pre-mixed paint. Before painting, roll the roller across a sheet of cardboard to ensure the paint is evenly distributed across the roller.

To reduce paint waste, we used lint-free 1/8″ solvent-resistant mohair sausage roller covers used for working with marine paints and resins. You can use up to 3/8″ inch roller covers using this technique—but test first. These mohair rollers are lint-free, but to ensure there was no lint, we rolled them over the sticky side of our masking tape to remove an loose fibers.

Work in small section and change rollers frequently. We used a 50/50 mixture of fine and medium grit additive in our Awlgrip. We did not do this with coarse grit, which we assume, would produce more obvious clumping if the paint is not throughly mixed.

A final coat, without grit, sealed the surface. Be sure to keep the coats thin-multiple thin coats are preferred over one heavy coat-and plan to apply the paint when there is minimal humidity. On all but a few tiny sections, the result was an even non-skid that was indistinguishable from a spray-on coating. When we recoat, we will likely do the broadcast method recommended by the manufacturers to see how it compares.

If are looking at ways to prevent slipping on step pads, stairs, or work stations (at the base of the mast, for example) and are not yet ready to embark on a paint project, check out our report on report on non-skid tape .

Taping: Use only high quality masking tape designed for outdoor use. Do not exceed the manufacturer’s recommended service period, otherwise you’re in for a big job removing tape one fleck at a time. Ralph Naranjo evaluated all the leading tapes from the leading manufacturer 3M in his report 3M Masking Tape Matchup . He also included techniques on following tight curves, which are common on non-skid sections.

Curing: Follow the makers recommendation for dry time, and be sure to allow the paint to fully cure before subjecting it to foot traffic. This allows the paint to achieve maximum hardness, making it more abrasion resistant and longer lasting.

Mat Installation: If you’re installing a self-adhesive mat, application is a no-brainer. Just be sure its where you want it before you stick it to the deck; contact adhesives don’t allow the small wiggle adjustments that epoxies do in application.

Testers also learned a few application lessons the hard way when installing nonskid mats with two-part epoxy. The epoxy usually has about an hour of pot life before it becomes permanently stuck to whatever its touching, so clean up any errant epoxy with a solvent as soon as possible.

Its also best to decide on the mats exact location before mixing the epoxy; you can use paper templates to help in this process. Be sure to leave a lip around the mat edge that is free of glue; the epoxy will squeeze into the bare area when the mat is put in place.

Regular Maintenance

Boat bath: Nonskid paints and mats should be cleaned regularly to remove abrasive salt spray and dirt. Wash with standard, mild boat soaps ( PS, January 2013 ) or household cleaners and a soft- to medium-bristled brush. Steer clear of bleach and other chlorinated or acid-based cleaners as they can affect the paints color pigments and UV inhibitors. Be sure to rinse the decks well with fresh water, when possible.

Mold and Mildew: To prevent mold and mildew, you can lightly scrub the surface with an ammonia/detergent solution. To spot clean areas that are heavily soiled or show mildew, you’ll likely need to step up to more aggressive cleaner. Pettit recommends its Bio-Blue 92; the blend of cleaning agents and silica grit also can be used to de-wax or etch during surface prep. Durabak recommends fighting mildew and stains with a disinfectant like Lysol, and KiwiGrip advises using bleach or a mild acid solution to remove mold and mildew stains.

Wax Not: While waxing can breathe new life into topside paint, the paint makers we talked to do not recommend waxing painted nonskid. Most nonskid paints and bead/powder additives have UV protection built in, and the paint formulas include UV absorbers, making waxing unnecessary.

Touch-ups: Address any peeling or worn nonskid paint as soon as possible. Most of the nonskid paints we tested are easily repairable: A bit of scuff sanding, cleaning, and touch-up painting will keep the coating from meeting an early demise.

Longevity expectations

Nonskids life expectancy can vary based on type (paint vs. mats, and paint type), boat location (UV-saturated South Florida vs. overcast Seattle), and how it is cared for. In our non-skid surface tests , the soft-foam mats we tested did not weather as well as more rugged mats like Treadmaster-nor did some one-part paints, but they can be freshened up with a little sanding and a recoat. For example, Pettit reports that EZ-Decks should perform well in Florida for about three years before needing a recoat.

A properly applied two-part LPU should deliver at least five years before needing recoating—you could get as long as ten. Less viscous polyurethanes like Durabak and KiwiGrip claim to last a decade, but in our experience with Durabak, five years is the maximum in the marine environment.

Practical Sailor Non-skid Tests

Over the years, Practical Sailor has conducted dozens of test comparing painted-on non-skid exterior coatings. We’ve also compared the heavy-duty textured mats, including faux teak and cork, that are applied with adhesive. Three long-term tests of these coatings and mat products are still ongoing.

Here is a summary of what we found so far:

For long-term use, a two-part polyurethane (LPU) paint with a textured additive will provide the most durable exterior non-skid surface. Among the two-part LPU paint kits that scored the highest in our past tests were Awlgrip Griptex additive (with Interlux Perfection) and polypropylene beads (with Epifanes LPU). Triflex Treadmaster was our top contender among the adhesive mats, although it had become extremely hard, almost brittle, after 10 years.

Among the textured paint products, Durabak has since been eclipsed by Kiwigrip and Interlux Interdeck for durability.(See Do-it-Yourself Nonskid Options , PS November 2013, and Non-skid Ten Years After .) We are currently looking at two relatively new products on the market, Pettit Tuffcoat, a rubberized textured coating with a two-part epoxy primer. And TotalTread, from Totalboat, a ready-mixed, slip-resistant polyurethane non-skid deck paint with texturing agents. Tuffcoat is effectively a marine version of a product that is popular for coating the beds of pickup trucks, and TotalTread is representative of the moderately priced, easy-to-apply, non-skid coatings.

We are also working on a 10-year update on faux teak vinyl mats. So far, the results are very similar, and our long-term testing has not yielded any big losers or winners. The budget-priced Plasdeck and Permateek had slightly grippier surfaces in our initial test. The thicker Dek-King and Flexiteek products were slightly cooler. Testers were also impressed by the cork infused Marinedecks grip and durability.(See Synthetics Go Toe to Toe , PS December 2015).

Remember that non-skid surface is only one element to onboard safety. Even the grippiest deck is of little use if you have to creep around shrouds, hurdle over cockpit coamings, or move around deck with nothing to grab. As you ponder your non-skid options, consider taking inventory of your boat’s ergonomic features, as described in Tech Editor Drew Frye’s report, (“ Tall-step Syndrome ,” PS February 2016).

If you are in the market for a new or used boat, be sure to look at Ralph Naranjo’s report on cockpit ergonomics (“ A Practical Look at Cockpit Design ,” PS April 2012 ).

Finally, if you are looking into breathing new life into an old boat with a cosmetic makeover, our recently published 4-Volume e-book “ Painting Your Boat From Bottom to Top ,” compiles and updates more than a decade of research and hard-won experience on marine coatings.

RELATED ARTICLES MORE FROM AUTHOR

On watch: this 60-year-old hinckley pilot 35 is also a working girl, leave a reply cancel reply.

Log in to leave a comment

Latest Videos

Cabo Rico 34 Boat Review

Super Shallow Draft Sailboat: The Leeboard Sharpie

Hans Christian 41T – Boat Review

Seven dead after superyacht sinks off Sicily. Was the crew at...

Latest sailboat review.

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

How to Articles | Bottom Paint Store

Learn more about boat paint applications and marine supplies.

How to Choose and Apply Non-Skid Boat Deck Paint for Safety and Durability

Why Non-Skid Deck Paint is Essential

Safety on boats is crucial, particularly on decks where water can create a slipping hazard. Whether for recreational purposes or professional boating, non-skid surfaces are essential to prevent accidents and ensure stability. Non-skid deck paint offers a practical solution that enhances traction and improves the overall appearance of the boat, making it a popular choice among boat owners.

Types of Non-Skid Deck Paint

One option is textured paint, which incorporates non-slip additives like silica, polymer beads, or rubber to create a rough surface that improves grip. Textured paints are commonly used in areas exposed to water, providing excellent traction. Another type is pre-mixed non-skid paint, which is convenient and easy to use, making it ideal for DIY enthusiasts. These paints come ready to apply with the non-slip additives already mixed in, ensuring consistency in texture. Some prefer additive-based non-skid solutions, which allow users to mix non-skid additives such as sand, silica, or specialized granules into regular marine paint. This offers the flexibility to customize the texture and non-slip performance based on individual needs.

Non-Skid is a pumice additive that can be added to most paints and gel coats to provide a slip resistant surface. Learn more.

Key Factors to Consider When Choosing Non-Skid Deck Paint

Durability is one of the primary considerations when selecting non-skid paint. The paint should be able to withstand marine conditions such as saltwater exposure, UV rays, and heavy foot traffic. Choosing a durable paint ensures that the non-skid properties remain intact over time. Ease of application is another important factor, particularly for those who plan to apply the paint themselves. Pre-mixed options simplify the process, while additive-based solutions offer more customization but require additional effort to prepare. Aesthetic preferences should also be taken into account.

Non-skid deck paints come in a variety of colors and finishes, giving boaters the ability to match their deck to the overall look of the vessel, whether they prefer a sleek, modern design or something more traditional. Additionally, it is essential to ensure the paint provides waterproofing to prevent water damage and includes UV protection to maintain the paint’s integrity under prolonged sun exposure. Both of these features contribute to the longevity of the paint.

Griptex is a polymer bead aggregate used to provide non skid deck and step areas when mixed with an Awlgrip topcoat. Learn more.

Step-by-Step Guide to Applying Non-Skid Deck Paint

The first step is preparation. Start by thoroughly cleaning the deck to remove any dirt, grease, or old paint that could interfere with the adhesion of the new paint. Once clean, sand the surface to create an even texture that allows the paint to bond properly. After sanding, wipe down the deck with a solvent to remove any remaining dust or debris, ensuring a clean and smooth surface.

Priming the deck is the next step, and depending on the paint you select, a marine-grade primer may be necessary. This primer helps the paint adhere to the surface more effectively and improves durability. When it comes to painting, apply the non-skid paint with a brush or roller, ensuring even coverage across the deck. It’s important to apply multiple thin layers rather than one thick coat, as this improves the durability and performance of the non-skid properties. Allow for sufficient drying time between each coat. Once the final layer is applied, give the paint ample time to cure before exposing the deck to foot traffic or water, as rushing this step can reduce the effectiveness and lifespan of the paint.

Maintenance Tips for Non-Skid Boat Deck Paint

To maintain the effectiveness of the non-skid surface, it’s important to clean the deck regularly using mild soap and water. Dirt and debris can accumulate over time, reducing traction and making the surface less safe. It’s also best to avoid using abrasive cleaners, as they can wear down the non-skid texture, diminishing its performance. Instead, opt for gentle cleaning methods that preserve the surface. In high-traffic areas, the paint may wear down over time. Periodic touch-ups or repainting may be necessary to maintain the non-skid properties, especially in areas that experience heavy use.

Top Non-Skid Deck Paint Brands

There are several reputable brands known for producing high-quality non-skid deck paints that combine durability, ease of use, and long-lasting performance. Interlux is recognized for its exceptional durability and UV resistance, making it an excellent choice for long-term use. TotalBoat offers a range of easy-to-apply paints that provide excellent traction and are favored by DIY boat owners. KiwiGrip is popular for its environmentally friendly formulation and customizable texture, allowing boaters to adjust the level of non-skid based on their needs. Rust-Oleum is a budget-friendly option known for its durability and resistance to water, making it a practical choice for those seeking a cost-effective solution.

Enhance Safety and Aesthetics with Non-Skid Paint

As you can see choosing the right non-skid deck paint is essential for ensuring both safety and aesthetics on your boat. By selecting a paint or additive that balances durability, ease of application, and visual appeal, you can enjoy a safer, more attractive deck that stands up to marine conditions. Investing in non-skid paint enhances your boating experience, providing peace of mind while also improving the overall appearance of your vessel. If you need any assistance selecting non skid boat paint feel free to contact the customer support team at Bottom Paint Store.

Ridetheducksofseattle is reader-supported. When you buy through our links, we may earn an affiliate commission. Learn more

The Best Boat Deck Paints (Non-skid, Fiberglass, Wood & More)

Written by Anthony Roberts / Fact checked by Jonathan Larson