Great choice! Your favorites are temporarily saved for this session. Sign in to save them permanently, access them on any device, and receive relevant alerts.

- Sailboat Guide

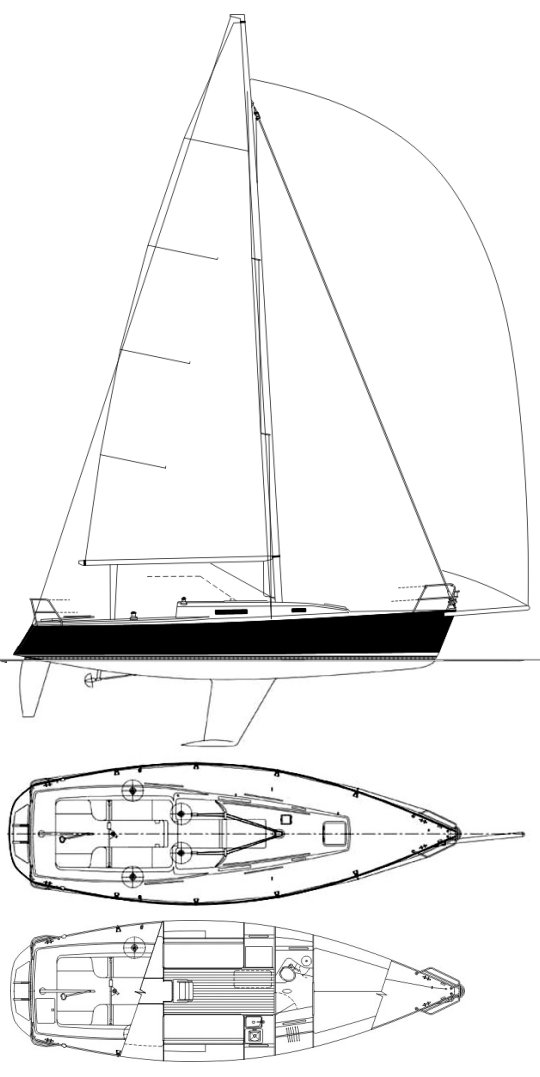

J/105 is a 34 ′ 6 ″ / 10.5 m monohull sailboat designed by Rod Johnstone and built by J Boats and Waterline Systems, LLC starting in 1995.

Rig and Sails

Auxilary power, accomodations, calculations.

The theoretical maximum speed that a displacement hull can move efficiently through the water is determined by it's waterline length and displacement. It may be unable to reach this speed if the boat is underpowered or heavily loaded, though it may exceed this speed given enough power. Read more.

Classic hull speed formula:

Hull Speed = 1.34 x √LWL

Max Speed/Length ratio = 8.26 ÷ Displacement/Length ratio .311 Hull Speed = Max Speed/Length ratio x √LWL

Sail Area / Displacement Ratio

A measure of the power of the sails relative to the weight of the boat. The higher the number, the higher the performance, but the harder the boat will be to handle. This ratio is a "non-dimensional" value that facilitates comparisons between boats of different types and sizes. Read more.

SA/D = SA ÷ (D ÷ 64) 2/3

- SA : Sail area in square feet, derived by adding the mainsail area to 100% of the foretriangle area (the lateral area above the deck between the mast and the forestay).

- D : Displacement in pounds.

Ballast / Displacement Ratio

A measure of the stability of a boat's hull that suggests how well a monohull will stand up to its sails. The ballast displacement ratio indicates how much of the weight of a boat is placed for maximum stability against capsizing and is an indicator of stiffness and resistance to capsize.

Ballast / Displacement * 100

Displacement / Length Ratio

A measure of the weight of the boat relative to it's length at the waterline. The higher a boat’s D/L ratio, the more easily it will carry a load and the more comfortable its motion will be. The lower a boat's ratio is, the less power it takes to drive the boat to its nominal hull speed or beyond. Read more.

D/L = (D ÷ 2240) ÷ (0.01 x LWL)³

- D: Displacement of the boat in pounds.

- LWL: Waterline length in feet

Comfort Ratio

This ratio assess how quickly and abruptly a boat’s hull reacts to waves in a significant seaway, these being the elements of a boat’s motion most likely to cause seasickness. Read more.

Comfort ratio = D ÷ (.65 x (.7 LWL + .3 LOA) x Beam 1.33 )

- D: Displacement of the boat in pounds

- LOA: Length overall in feet

- Beam: Width of boat at the widest point in feet

Capsize Screening Formula

This formula attempts to indicate whether a given boat might be too wide and light to readily right itself after being overturned in extreme conditions. Read more.

CSV = Beam ÷ ³√(D / 64)

Embed this page on your own website by copying and pasting this code.

- About Sailboat Guide

©2024 Sea Time Tech, LLC

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

The J105 is a 34.5ft fractional sloop designed by Johnstone and built in fiberglass by J Boats since 1995.

The J105 is a light sailboat which is a very high performer. It is very stable / stiff and has a low righting capability if capsized. It is best suited as a racing boat. The fuel capacity is originally very small. There is a very short water supply range.

J105 for sale elsewhere on the web:

Main features

| Model | J105 | ||

| Length | 34.50 ft | ||

| Beam | 11 ft | ||

| Draft | 6.50 ft | ||

| Country | United states (North America) | ||

| Estimated price | $ 0 | ?? |

Login or register to personnalize this screen.

You will be able to pin external links of your choice.

See how Sailboatlab works in video

| Sail area / displ. | 23.65 | ||

| Ballast / displ. | 43.87 % | ||

| Displ. / length | 134.77 | ||

| Comfort ratio | 15.85 | ||

| Capsize | 2.23 |

| Hull type | Monohull fin keel with bulb and spade rudder | ||

| Construction | Fiberglass | ||

| Waterline length | 29.50 ft | ||

| Maximum draft | 6.50 ft | ||

| Displacement | 7750 lbs | ||

| Ballast | 3400 lbs | ||

| Hull speed | 7.28 knots |

We help you build your own hydraulic steering system - Lecomble & Schmitt

| Rigging | Fractional Sloop | ||

| Sail area (100%) | 577 sq.ft | ||

| Air draft | 0 ft | ?? | |

| Sail area fore | 274.05 sq.ft | ||

| Sail area main | 302.95 sq.ft | ||

| I | 40.60 ft | ||

| J | 13.50 ft | ||

| P | 41.50 ft | ||

| E | 14.60 ft |

| Nb engines | 1 | ||

| Total power | 20 HP | ||

| Fuel capacity | 12 gals |

Accommodations

| Water capacity | 5 gals | ||

| Headroom | 0 ft | ||

| Nb of cabins | 0 | ||

| Nb of berths | 0 | ||

| Nb heads | 0 |

Builder data

| Builder | J Boats | ||

| Designer | Johnstone | ||

| First built | 1995 | ||

| Last built | 0 | ?? | |

| Number built | 0 | ?? |

Modal Title

The content of your modal.

Personalize your sailboat data sheet

- AROUND THE SAILING WORLD

- BOAT OF THE YEAR

- Email Newsletters

- America’s Cup

- St. Petersburg

- Caribbean Championship

- Boating Safety

- Ultimate Boat Giveaway

One-Design Showcase

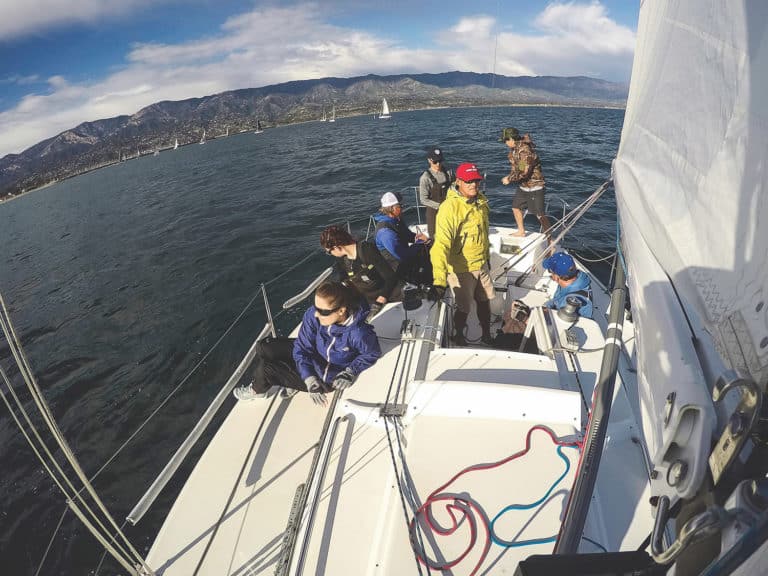

About the J/105

Introduced in 1991 as the first modern day keelboat with bow-sprit and asymmetric spinnaker, the J/105 today is the most successful one-design keelboat class over 30′ in the USA with over 680 boats sailing worldwide. The Class Association is an owner-managed organization with strict one-design rules, a world class website, and offers the best and most active one-design racing in the USA today. The Class Rules include an owner-driver rule, tight restrictions on Category 3 professionals, and annual sail purchase restrictions to keep racing affordable and as Corinthian as modern one-design can be.

Class Information:

Class Contact: Christopher & Julie Howell

Class Contact Email: [email protected]

Class Contact Phone: 440-796-3100

Class Website: j105.org

Social Media: Facebook | Twitter

Class Specs

LOA: 34 ft. 6 in.

LWL: 29 ft. 6 in.

Beam: 11 ft.

Draft: 6 ft. 6 in.

Weight: 7750 lbs.

Adult Summer Camp’s New Home

The Pacific Northwest’s once-glorious race week relocates to start a new life

Taken For a Ride

An impromptu beer can race doesn’t require thumbs out —but the experience is two thumbs up

From Near and Far

The 2016 Helly Hansen NOOD Regatta in Annapolis is a one-design destination.

Annapolis Youth Sailors Selected to Helly Hansen Junior Crew

The average age of competitors just got a bit lower for the Helly Hansen NOOD Regatta in Annapolis.

- Digital Edition

- Customer Service

- Privacy Policy

- Terms of Use

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

By Product Categories

Small Boat Blocks

Big Boat Blocks

Complementary Hardware

Travelers & Genoa Leads

Mainsail Handling

Headsail Handling

Mooring Solutions

Spare Parts

Accessories

Harken Canvas

Sportfishing

Fly Soft-Attach Blocks

Carbo Air Blocks

Small Boat Classic

Flip-Flop Small Boat

GP Catamaran Ceramic Mainsheet Systems

Protexit™ Exit Blocks

Through-Deck

Wire High-Strength

Dinghy Vang

Small Boat Deck Organizers

Midrange Classic

Midrange Deck Organizers

Zircon Blocks

Element Blocks

Black Magic Air Blocks

Cruising ESP Blocks

Megayacht Blocks

Stainless Steel Blocks

Black Magic Air Runners

FlatWinder Powered Blocks

Mastbase Blocks

Over-the-Top

Crossover Blocks

Big Boat Deck Organizers

Cam Cleats & Kits

Cam Cleat Accessories

Cam Cleat Bases

Stand-Up Bases

Deck Organizers

Spinnaker Pole Cars

Soft Attachments

Fixed Padeyes

Removable Padeyes

Bolt-Down Fairleads

Grand Prix Jib Leads

Halyard Tensioners

Tiller Extensions

Peter's Desk Drawer

Dinghy Jib Leads

Crossbow Pivoting Self-Tacking Jib Traveler

13 mm Micro

22 mm Small Boat

27 mm Midrange

32 mm Big Boat

Windward Sheeting

42 mm Mini-Maxi

T-Track Genoa Lead

Access Rail System

13 mm AA Battcar System

22 mm A Battcar System

27 mm B Battcar System

32 mm C Battcar System

18 mm Switch Battcar System

26 mm Switch Battcar System

26 mm Trysail Switch

32 mm Switch Battcar System

32 mm Trysail Switch

40 mm Switch Battcar System

40 mm Trysail Switch System

Furling Mainsail Outhaul Systems

Single Line Reefing

Harken Vang-Master

Carbo Racing Foil

Small Boat Furling

Small Boat Underdeck

Reflex Furling

MKIV Jib Reefing & Furling

MKIV Underdeck Jib Reefing & Furling

Furling Accessories

Powered Furling

MKIV Ocean Furling

SnubbAir (Not a Winch)

Grand Prix Winches

Air Winches

Circuit Breakers

Analog Switches

Digital System Switch

Aluminum, Chrome & Bronze Winch Handles

Carbo OneTouch Locking Winch Handle

Service Kits

CLR Mooring Winches

Electric Captive Reel Winches

Hydraulic Captive Reel Winches

UniPower Radial

Single-Acting Integral Backstay Adjuster

Single-Acting Cylinders

Locking Cylinders

Double-Pull Cylinders

Grand Prix Cylinders

Hydraulic Cylinder Rod End Blocks

Hydraulic Cylinder End Fittings

Control Valves

Control Manifolds

Control Panels

Compact Control Panel

Rotary Pumps

Hydraulic Pump Handles

Power Systems

Repair Kits

Ball Bearings

Block Spare Parts

Traveler Cars

Furling Spare Parts

Winch Spare Parts

Winch Service Kits

Blockheads Gear

Promo & Gifts

Marine Grip

Blue Performance

Jeep/Truck tops

Garage storage

One-design Covers

Boat accessories

Canvas bags

By Type of Sailing

Dinghy / One-Design

Offshore Racing

Coastal / Day Cruising

Bluewater Cruising

Megayachts / Custom

Service Guide

Tech/Service

deck layouts

Data Sheets (SDS)

How to choose

System diagrams

Calculators

Reeving diagrams

Traveler Purchase Selection Guide

How to Choose

Testimonials

Hoister Videos

Request a Quote

Request Samples

Fabric details

Cover Styles

Canvas Videos

Contract Services

Materials and Components

Our Equipment

Contract Cut-and-Sew Project Spotlight

- Harken at the front

- Safety & Rescue

Support / One-design deck layouts

J/105 Deck Layout

Gross-Trim, Fine-Tune Mainsheet

The divided cascading system runs the powerful fine-tune lead aft, allowing the helmsman to easily optimize sail shape on a light air beat. The gross-trim runs forward to the trimmer for fast mark roundings. To use this efficient system, simply add a 144 swivel base and third-party mainsheet adapter plate to your existing hardware.

MKIV Unit 1 Furler

MKIV's are easy to adjust for reefing and furling. When racing in non-class events, J/105 sailors can take the spool off and use the double-groove foil for fast sail changes.

If you would like to link to or reprint this article please contact [email protected]

Class History

The J/105 is a family racer/cruiser that combines a simple sailplan, clean deck layout and practical interior, with enough get-up-and-go to suit the most avid competitor. With sustained speeds of over 14 knots, this maneuverable keelboat features cockpit control at its best: an asymmetrical pole-launched chute, double-spreader fractional rig, lots of sail area and a roller furling jib.. The J/105 is optimized for shorthanded sailing; it can easily be cruised by two or raced by three or four. It was selected as Boat of the Year in the Racer/Cruiser category by Sailing World magazine.

Links J/105 Class McLube™

Boat Specifications

Loa: 34.5 ft (10.51 m) LWL: 29.5 ft (8.99 m) Beam: 11.0 ft (3.35 m) Draft: 6.5 ft (1.98 m) Displacement: 7.750 lb (3, 515 kg) Lead Keel: (3,400 lb (1,542 kg) J: 13,5 ft (4.12 m) P: 41/5 ft (12.65 m) E: 14.6 ft (4.45 m)

Related products

27mm High-Load Car — Stand-Up Toggle, 4:1

40mm Stand-up Block

57mm Fiddle Ratchet Block — Swivel, Becket

57mm Fiddle Block — Swivel

57mm Fiddle Ratchet Block — Swivel, Becket, Cam Cleat

75mm Ratchet Block — Swivel

75mm Block — Swivel

76mm Fiddle Block

Unit 1 MKIV Jib Furling System

Standard Cam-Matic® Cleat - 150

Standard Cam Base — Swivel

46 Self-Tailing Radial Aluminum Winch — 2 Speed

35 Self-Tailing Radial Aluminum Winch — 2 Speed

57mm Aluminum Double Footblock

Product categories.

- United States

- New Zealand

- United Kingdom

Harken will be closed on Thursday, Sep. 12 starting at 11 a.m. for our annual Sail Day. Any orders placed after 3 p.m. Wednesday, Sep. 11 will be processed on Friday.

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Blue Jacket 40 Used Boat Review

Catalina 270 vs. The Beneteau First 265 Used Boat Match-Up

Ericson 41 Used Boat Review

Mason 33 Used Boat Review

How to Create a Bullet-Proof VHF/SSB Backup

Tips From A First “Sail” on the ICW

Tillerpilot Tips and Safety Cautions

Best Crimpers and Strippers for Fixing Marine Electrical Connectors

Polyester vs. Nylon Rode

Getting the Most Out of Older Sails

How (Not) to Tie Your Boat to a Dock

Stopping Mainsheet Twist

Fuel Lift Pump: Easy DIY Diesel Fuel System Diagnostic and Repair

Ensuring Safe Shorepower

Sinking? Check Your Stuffing Box

What Do You Do With Old Fiberglass Boats?

Boat Repairs for the Technically Illiterate

Boat Maintenance for the Technically Illiterate

Whats the Best Way to Restore Clear Plastic Windows?

Stopping Holding-tank Odors

Giving Bugs the Big Goodbye

Galley Gadgets for the Cruising Sailor

The Rain Catcher’s Guide

Sailing Gear for Kids

What’s the Best Sunscreen?

UV Clothing: Is It Worth the Hype?

Preparing Yourself for Solo Sailing

R. Tucker Thompson Tall Ship Youth Voyage

On Watch: This 60-Year-Old Hinckley Pilot 35 is Also a Working…

On Watch: America’s Cup

On Watch: All Eyes on Europe Sail Racing

Dear Readers

- Sailboat Reviews

On its 10th birthday, the J/105 enjoys an immensely strong class association fueled by a group of owners who wouldn?t sail any other way than fast and easily. Problems with the boat are few, and right out front.

Some years ago – never mind how long precisely – Rodney Johnstone, a Connecticut schoolteacher, changed careers and became an ad salesman for a marine magazine. Then, still unsatisfied, he enrolled in the Westlawn School of Yacht Design. He didn’t graduate, but he did became so successful designing the line of J-Boats that the school gave him an honorary degree so it could use his name in advertisements.

This Horatio Alger story begins appropriately enough with rags, in this case, Ragtime, the prototype of the J/24 Rod built in his garage. During its first season of racing on Long Island Sound, 1976, the flat-bottomed speedster took 17 of 19 starts. Rod’s brother Robert (Bob) was marketing manager for Alcort/AMF, and asked his bosses if they’d like to build Ragtime on a production basis. In one of the few missed opportunities ever to occur in the sailing industry, an industry where “no” is usually the smart choice, they indeed said no.

Ha. So Bob did what any self-respecting man would do – he quit. J-Boats was formed by the brothers in 1977, and Everett Pearson’s TPI began building the J/24. By 1986 more than 4,200 had been sold. By 1997, there were more than 5,200.

The appeal of the J/24 is partly due to just those numbers; there are large, competitive fleets around the U.S. and the world. J-Boats licensed builders in Australia, Japan, Italy, England, France, Brazil and Argentina. But it’s more than that. The J/24 is an affordable option for people who want to race one-designs bigger than daysailers, but don’t have a hundred grand a year and more for grand prix racing. If you really want to do Key West Race Week, the J/24 can be trailered behind the family car.

While the J/105 isn’t nearly as trailerable as the 24 (an ad for the boat states flatly that it’s “for people who live near where they sail”) it does echo that theme of maximum bang and flexibility for the buck for people who intend to sail rather than sit still.

Introduced in 1992, the J/105 isn’t alone in the sport-boat genre, but it was certainly a progenitor of the species. PS editor Doug Logan, reviewing the boat for Sailing World soon after its appearance, saw a confluence of ideas that had been expressed in widely different types of boats – like Bill Lee sleds, Farrier’s trimarans, and Schumacher’s racer/cruisers – coming together in the J/105. The staggering idea at the time was the flat rejection of interior volume and cushiness in favor of simplicity, performance, and good looks. And this in a boat that was intended to cruise at least a bit, as well as race as a one-design. It was truly a bold move on Rod Johnstone’s part – and it has worked, though more on the racing side than on the cruising side. In its 10-year production run, more than 500 J/105s have been built.

The Design Like most other J-Boats, the 34-1/2-foot, 7,750-pound J/105 is for people who enjoy speed and responsiveness. If you drive a Lincoln Town Car, buy a Tartan 4600. If you drive a Boxster, buy a J/105.

Anyone who has planed a daysailer knows the thrill of getting the hull up out of the water and boogeying. “Now,” designers like Rod Johnstone must have mused, “if only you could do that on a bigger keel boat.”

The speed available in a keelboat today was almost unthinkable before George Hinterhoeller, who no doubt had the same musings, designed and built his breakthrough Shark 24, way back in 1959. One Shark averaged more than 10 knots in an 80-mile race.

Rod Johnstone gets speed the same way Hinterhoeller did, with light weight, a flattish bottom, and a big rig. The J/105’s displacement/length ratio (D/L) is just 135, which makes it a very light displacement boat, and a sail area/displacement ratio (SA/D) of 24. These numbers make even the J/35, arguably one of the most successful mid-size racers of the modern era, look tame by comparison: D/L of 174 and SA/D of 21.

Overhangs are minimal and the waterline is long, at 29′ 6″. Beam is generous at 11′ for good form stability, draft is deep (6′ 6″) for ultimate stability, freeboard is low to reduce windage, and the cockpit is long, so there’s room for the crew, whether racing or just fooling around. The seats are 6′ 5″, sufficient yardage to sleep on. A 5′ 6″ shoal keel is available, and the one of choice in areas like the Chesapeake Bay. The limit of positive stability (LPS) is given at between 125° and 127° for shoal draft models, and about 130° for the deep keel. These exceed the generally accepted minimum of 120° for offshore sailing.

The J/105 has the same bow as the J/80, J/90 and others in the line; that is, a minimally raked profile with more curve and not as much “plumbness” (if there is such a word) on paper as appears in the water. From a purely aesthetic point of view, the line isn’t that interesting, but here form follows function. It does what it’s supposed to. The reverse transom has a molded cavity with ladder for swimming and boarding.

The keel is a deep, narrow fin with a slightly raked leading edge. You don’t want to hit a rock with this configuration, as you’re unlikely to ride over it. And if you do, check the floors under the cabin floorboards to see if you’ve wrenched anything.

The cabin is low profile, befitting a performance boat, with just two windows per side.

The rig is fractional, to permit bending the mast for optimal sail shape.

Construction All J-Boats are built by TPI in Warren, Rhode Island, using the patented SCRIMP process. We’ve written about it before. In a nutshell, the fiberglass structures, principally the hull and deck, are laid up dry; that is, without resin. Layers of biaxial fiberglass fabric are laid into the mold, then sealed in a plastic “envelope” or bag as it were. A polypropylene woven fabric is spread on top of the laminate so there’s room for the resin to migrate vertically. When a vacuum is applied, air is sucked out of the envelope and resin is drawn in through a network of feeder tubes. This enables the builder to achieve a 70:30 glass-to-resin ratio, thought by many to be the ideal mix (some think it’s a little thin on the resin, preferring 65:35 or even 60:40).

With so little resin in the laminate, a core is definitely required to restore stiffness. J-Boats and TPI favor Baltek end-grain balsa, in this case its AL600 product. There are on the owners’ website a few complaints about print-through (seeing the pattern of the underlying fiberglass through the gelcoat) and flat spots where gelcoat is nearly absent.

As an aside, a major benefit of closed-molding techniques, in which the chemical reaction of the resin and catalyst takes place inside a bag and the resultant gases are exhausted directly out of the building, is a much cleaner air environment for the worker – and fewer headaches for the builder trying to meet EPA and OSHA guidelines for volatile organic compounds (VOCs).

TPI was a pioneer in studying and offering anti-blister protection. Today it uses a vinylester resin from Interplastic as an outer coat, under the gelcoat. A 10-year warranty against blistering is given.

The hull is stiffened by fore-and-aft and transverse solid glass hat sections molded with the hull at the time of initial lay-up. Before hull #156, these keel stringers and floor members were solid glass tabbed in after the hull was molded. The new method avoids secondary bonding, which is not as strong, where the beams (often wood or foam) are glassed to the finished hull. A superior secondary bond is achieved when the hull resin is still “green,” but nothing beats laying everything up together.

The main structural bulkhead is tabbed to the hull and deck, which is far preferable to the all-too-common practice of fitting the bulkhead into a molded groove in the headliner.

The keel stub is fiberglass and the ballasted bulb is lead.

The balanced spade rudder is fiberglass, as is the rudderpost, which is laid up with a quadraxial fabric. There are upper and lower bearings, and both have been a source of aggravation for many owners. According to the J/105 owners’ website, the bearings are aluminum, which corrode when in contact with the copper in bottom paint. Jeff Johnstone says they have a three-to-five year life, “sometimes even shorter if sacrificial zincs were allowed to dissolve, or if the Mylar spacer between the stainless and aluminum was removed, or if there was bottom paint on metallic parts of bearing, or simply if the bearing was not regularly rinsed out with fresh water a few times per season.”

Some owners have been replacing them with Harken plastic bearings, but now other sources must be found because Harken is no longer making bearings. The retrofit is not an easy job, say the owners who’ve done it.

Standard steering is a laminated wood tiller with Spinlock hiking stick. Wheel steering is optional, and boats with it command slightly higher resale prices. At least one owner said a tiller-steered boat can be hard to handle in heavy weather, but it’s hard to beat the feel of a tiller, and its simplicity must be admired.

Another steering-related problem has been the emergency tiller. Some owners say their tiller attaches at right angles to the centerline, so that when the rudder is centered, the tiller is hard to port. Other owners said their tiller didn’t fit when the boat was commissioned. These problems are correctable and should be checked out on purchase, new or used.

The Bomar hatch on the foredeck has been a source of aggravation. It’s opened when changing sails, and when laid flat on deck the welds in the frame are prone to cracking. (This stainless steel hatch is of good quality, but not as good as Bomar’s cast aluminum series of hatches). At first Bomar thought they should take responsibility and replaced a number at no cost. When it was determined that deck camber and opening past 180° combined to cause the failures, a deal was worked out with J-Boats to offer for $35 a bumper (to prevent opening the hatch beyond 180°) and a weld repair kit.

Remaining complaints include failure of cockpit seat locker hasps, cove stripes that are not straight or not of a uniform width, or that there are scribe marks for a cove stripe that doesn’t exist.

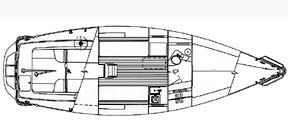

Interior The accommodation plan is straightforward with a 7′ V-berth in the bow. Moving aft there’s an enclosed head with optional shower, and a hanging locker. The split galley is just aft of the main bulkhead, with a nav table to port and a stainless steel sink and space for an optional one-burner Origo alcohol stove to starboard. The ice box is actually a 54-quart portable cooler kept under the companionway ladder. Obviously it can’t be as well insulated as a built-in icebox, but it does save weight, and that’s the operative concept here. The portable freshwater tank holds just 5 gallons.

Opposing 6-1/2′ settee berths are port and starboard, with stowage bins outboard. These have gray vinyl trim and cold-molded teak cap moldings. Quarter berths (one or two) are optional, and seem to be favored by those owners who have them, though Johnstone says few boats are ordered that way. Length is 6-1/2′.

The trim theme is light and easy maintenance. The overhead and ceilings (hull sides) are covered with vinyl. Seat cushions are upholstered with Sunbrella. If you spring for the optional cockpit cushions they can double as backrests for the settees; they certainly increase comfort.

Other options include automatic electric bilge pump, shore power, cockpit/cabin table, sink in the head countertop, 20-gallon freshwater tank under the starboard berth, utensil drawer in galley, and a chart drawer under the nav table big enough to hold Chart Kits. They all sound nice to have, but together must add several hundred pounds.

The standard forward portlights are fixed, but you can have opening ones with screens for an extra charge. It’s also possible to have two ports in the aft face of the cabin trunk, either side of the companionway.

The interior is simple, and therein lies its attractiveness. Too many boats grow overly complicated as owners try to replicate the comforts of home. The J/105 resists that urge and rewards the owner with more time sailing (faster sailing at that), and less time fixing things.

The original floorboards were said to be weak by many owners. Many rotted when water entered the exposed end grain of the plywood. The problem was caused by the shallow bilge (a drawback of flat-bottom boats); when the boat heeled, the bottom of the boards got wet. Later, the plywood was covered with a plastic, but some of these $700 boards delaminated because the end grain still wasn’t sealed. Now, Johnstone says, “The standard for the last three years has been the Wear-rite synthetic teak and holly sole, which is used on a lot of charter boats in the Caribbean and is much more forgiving of punishment.” J-Boats seems anxious to correct such problems and customer service seems to be quite good.

For many people, the most vexing problem will be the headroom – just 5′ 4″ in the saloon, unless you stand in the open companionway hatch under the dodger. The lack of headroom isn’t an acute problem for everyone, since virtually everything belowdecks is done sitting, lying down, or bending over. The low overhead would, however, become tedious if you were cooped up for several days on board in rainy weather.

Performance Now the fun part. The J/105 is fast and handles like a sports car. Indeed, sprit boats like the 105 created the so-called “sport boat” genre.

Powering the 105 is a tall, keel-stepped, tapered fractional-rig mast with double airfoil spreaders. Mast and boom are painted with Awlgrip polyurethane. All stays are Navtec rod. Shrouds are continuous, meaning they are a single piece; this avoids potential problems at extra terminal fittings, such as at spreaders, but requires careful bending of the guide tubes at the spreader tips. Continuous or discontinuous, rod rigging saves weight aloft and reduces windage.

On early boats, the balsa core in the deck was not removed in the area where chainplates pass through. Because chainplates work on any boat, it’s nearly impossible to keep that interface watertight. As a result, some cores got waterlogged. On later boats, the core was removed in favor of solid glass. Then, the little bit of water that migrates down the chain plate causes no harm – unless it enters bolt holes drilled in plywood bulkheads. So, bulkheads should be checked, too.

Hardware includes a Harken furler for the jib, Lewmar 44AST 2-speed primary winches, Lewmar 30AST 2-speed halyard and secondary winches, Schaefer turning blocks, Spinlock rope clutches, Harken traveler and mainsheet systems, carbon fiber sprit with under-deck launching and retraction system, Sailtech backstay adjuster, and Hall Quick Vang. This is all top quality gear; Practical Sailor has long rated the expensive Quick Vang as the best rigid vang made.

The asymmetrical spinnaker is in a snuffer, so that jibing can be a one-person operation. The spinnaker can be partially reefed.

A number of owners have mentioned water entering the boat through the sprit tube in the forward cabin, inspiring a number of creative solutions involving neoprene rubber and various lip seals.

When Doug Logan test sailed an early J/105 10 years ago off Miami, conditions were ideal for showcasing the boat’s strengths – a 20-knot northeasterly and three-foot waves. “For the better part of an hour we maintained speeds between 12.5 and 13.5 knots, never lower than 12 and up to 14.8 at the top end. This wasn’t a stomach-churning reach either. We had excellent control of the boat, and didn’t have to work hard.”

On the way back upwind, the boat was overpowered due to the lack of a reefing line. “Even so, we made 7.5 knots with the sheets just slightly eased.”

(The full Sailing World review is on the J/105 page at the J-Boats website, www.jboats.com , under “Less Is More.”)

Owners say you can sail with full main and jib up to about 22-25 knots, after which they switch down to a storm jib, and at around 30 knots put a reef in the mainsail.

A class controversy involves adjustable genoa sheet leads. Class racing rules prohibit the use of block and tackle and bungy cord to move the car from the cockpit. Instead, a crewmember has to go on deck and manually move the car. If there’s a load on the car, rather than easing the sheet (and losing speed) some people try stepping on the sheet forward of the car so that it can be moved. This, say proponents of adjustable leads, is dangerous. Opponents say adjustable lead systems are expensive and unnecessary. Some owners have installed adjustable systems for general-purpose use, but have pins installed in the cars for use when racing.

The auxiliary is a Yanmar 2GM20F diesel, which means two cylinders, 20-horsepower, freshwater cooled. A number of owners note that it jumps around a fair amount on its soft mounts, which in some installations has made dripless shaft seals leak. For those owners, a better alternative might be one of the dripless packing materials, such as Drip Free, in a conventional packing gland.

Conclusion By all measures, the J/105 has been, and continues to be, a considerable success. The reasons are simple: It’s a simple boat that’s fast and fun to sail.

Several decades ago we judged quality by weight: the heavier the boat, the better the quality and the higher the cost. High-tech composite construction has turned that axiom inside-out. Now you pay more for less, so to speak: epoxy and vinylester resins cost more than polyester; modern directional and high-strength fabrics and fibers cost more than chopped strand mat and woven roving; and vacuum bagging and infused resin molding methods like SCRIMP cost more than chopper gun spray jobs and hand lay-ups. Further, the tapered spars used on J-Boats cost more than the telephone poles found on most boats. Then there’s the carbon fiber sprit, rigid boom vang, and other stuff that’s not part of your standard cruising boat package. All this is to try to explain the average out-the-door price of a new J/105 of about $150,000. Prices of recent-year used boats range from $85,000 to $130,000 depending on equipment and condition. Deals are better on older boats (see the price history on a 1992 model above). Bear in mind that most J/105s will have been sailed flat-out. They don’t seem to sit around the yard much.

Also With This Article Click here to view “Used Boat Price History: J/105 – 1992 Model.”

Contact – J-Boats, 401/846-8410, www.jboats.com .

RELATED ARTICLES MORE FROM AUTHOR

Leave a reply cancel reply.

Log in to leave a comment

Latest Videos

Cabo Rico 34 Boat Review

Super Shallow Draft Sailboat: The Leeboard Sharpie

Hans Christian 41T – Boat Review

Seven dead after superyacht sinks off Sicily. Was the crew at...

Latest sailboat review.

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

J/105 Class Association

Class contact information.

Click below

Class Email

Class Website

One-Design Class Type: Keelboat

Was this boat built to be sailed by youth or adults? Both

Approximately how many class members do you have? 300

Photo Credit:Christopher Howell

Photo Credit: Christopher Howell

About J/105 Class Association

Introduced in 1991 as the first modern day keelboat with bow-sprit and asymmetric spinnaker, the J/105 today is the most successful one-design keelboat class over 30′ in the USA. The Class Rules include an owner-driver rule, tight restrictions on Category 3 professionals and annual sail purchase restrictions to keep racing affordable and as Corinthian as modern one-design can be.

Boats Produced: Approx. 690

Class boat builder(s):

Approximately how many boats are in the USA/North America? Approx. 500

Where is your One-Design class typically sailed in the USA? List regions of the country:

Does this class have a spinnaker or gennaker? Yes

How many people sail as a crew including the helm? 5-7

Ideal combined weight of range of crew: 1,102 lbs.

Boat Designed in 1991

Length (feet/inches): 34.5 Ft.

Beam: 11 Ft.

Weight of rigged boat without sails: 7,750 lbs.

Draft: 6.5 Ft.

Mast Height: 42 Ft.

Back to One-Design Central

Copyright ©2018-2024 United States Sailing Association. All rights reserved. US Sailing is a 501(c)3 organization. Website designed & developed by Design Principles, Inc. -->

ONE DESIGN // J/105

Introduced in 1992, the J/105 is the most successful modern one-design keelboat class over 30' in the world. There are J/105 one design class starts in virtually all major sailing centers across the United States and several in Europe. There are approximately 700 boats and 25 fleets worldwide. The strict owner driver and amateur crew member requirements has helped make this class a huge success. Doyle J/105 sails are winning throughout the country. When you want to put in a winning performance in your J/105, contact your local Doyle Sails Expert.

Class Mainsails: PB AP Mainsail 7oz Yarn Tempered Dacron. The sail features a large upper roach which is extended above the 3/4 measurement point. This makes for more power and better point. This sail has been proven in all wind conditions.

PB MH Mainsail sing a heavier 8oz Cloth for windier areas. This sail is a bit more draft forward with a straight exit and excels in winds over 10 knots but can still win on the light days.

Class Jibs: Stratis custom laminate using a blend of Carbon and Technora for maximum shape holding. Custom fiber layout for efficient use of the materials for the best sail we can make.

PB #1 Stratis Carbon Jib This jib is a killer sail in anything under 20 knots. The twist is perfect. The sail also features several advancements which separate the PB sails from the other brands. The sail has an aggressive foot round to put the foot on the deck. We also have a special frack friendly clew patch. So you can frack without damage to your jib on those light and lumpy days. Film/Film laminate with black fibers

PB #3 Jib now with light taffetas is the classic blade designed for 14 knots plus. It has a flatter, draft forward shape with less foot round using a strong taffeta covering to hold up under the toughest conditions. White custom light taffeta cover black fibers.

Class 89sm Spinnaker PB Spinnaker this is becoming a classic. It gets the job done in any wind strength. With the heavy class cloth weight and virtually exclusive windward leeward racing we have found no gain from having a different shape for the number two spinnaker. We suggest caring a new one and a backup and saving your tags for the extra jib. The spinnaker has specially designed soft patches which have saved weight and make launching easier.

Get in touch with an expert below or contact your local loft here

TUNING GUIDE

MEET THE TEAM

Paul Beaudin Doyle New York City 800 237 4453 [email protected]

2001 J Boats J-105. J/105. J105 Technical Specs

General data about j boats j-105. j/105. j105.

| Brand | |

| Model | |

| Boat Type | |

| Category | |

| Year Of Production | |

| Condition (New/Used) | |

| Country | |

| Fractional Ownership | |

| Fuel (Gas/Diesel) | |

| Hull Material Used | |

| Length | |

| Selling Price | |

Engine and Power Specs

| Folding Props | |

| Engine manufacturer | |

| Engine Series | |

| Engine Location | |

| Engine Drive | |

| Engine Built Year | |

| Boat Propeller |

Dimensions And Wieght

| LOA (Length Overall) | |

| L.W.L(Length WaterLine) | |

| Displacement (Weight) | |

| Boat Maximum Draft | |

| Beam Width | |

| Ballast System Weight |

Detailed Specifications

| Number of Heads (Watercraft) | |

| Manufacturer | |

| Gas Tank Size | |

| Boat Designer |

Features And Equipments

Other equipments.

| Wheel and binnacle cover with pocket for cp |

| Ullman - 2007 class jib |

| Spinnaker sock |

| Screens for all ports |

| Red vc offshore bottom paint - 2011 |

| Raymarine e7 hybrid touch cp at helm |

| Out haul - 12:1 upgrade |

| Life preservers |

| Lazy jacks |

| Infinity speakers in cabin plus cockpit speakers |

| I70 multi function 2018 |

| Factory installed genoa tracks |

| Doyle - 2011 class jib |

| Doyle stratus carbon - 2018 class jib |

| Cockpit / salon table |

| Clarion marine am-fm-cd player with ipod connection |

| Both mains configured with fasttrack slides |

| Bosun's chair |

| Boat hook |

| Blue mainsail and helm cover |

| At last check, only 2lbs over class minimum |

| Anchor and rode/chain |

| Analog / digital wind |

| 4 dock lines & 3 fenders wtih covers |

| 2020 insurance survey |

Interior Specifications

| Marine battery charger |

Exterior Features

| Mainsail cover |

| Cockpit cushions |

Electronical And Electrical Info

| Navigation and interior lighting |

| Factory shore power with cord |

| Dc & ac breaker panels |

| 2 batteries |

Deck Hardware

| Dodger |

| Cooler |

J Boats J-105. J/105. J105

- J Boats provided us with the latest version of its J-105. J/105. J105 service repair manual

- Find All mechanical and electrical parts and accessories of J Boats J-105. J/105. J105 Sail here

J Boats J-105. J/105. J105 competitors

J/105 Shoal draft

Sailboat specifications.

- Last update: 13rd March 2020

J/105's main features

J/105's main dimensions, j/105's rig and sails, j/105's performances, j/105's auxiliary engine, j/105's accommodations and layout.

Similar sailboats that may interest you:

The Worldwide Leader in Sailmaking

- Sail Care & Repair

- Sailing Gear

- Find A Loft

- Sail Finder

- Custom Sails

- One Design Sails

- Flying Sails

- New Sail Quote

- 3Di Technology

- Helix Technology

- Sail Design

- AEROTECH Spinnaker Cloth

- NPL RENEW Sustainable Sailcloth

- Sailcloth & Material Guide

- Polo Shirts

- Sweaters & Cardigans

- Sweatshirts & Hoodies

- Accessories

- Shop the look

- Mid & Baselayers

- Deckwear & Footwear

- Luggage & Accessories

- Fall Winter '24

- North Sails x 37th America's Cup

- Sailor Jackets

- SALT X North Sails

- NS x Slowear

- T-shirts & Tops

- Sailor Jacket

- Sustainability

- North Sails Blog

- Sail Like A Girl

- 37th America's Cup

- Icon Sailor Jacket

- Our Locations

- Certified B Corporation

- North SUP Boards

- North Foils

- North Kiteboarding

- North Windsurfing

SAIL FINDER

SAILING GEAR

COLLECTIONS & COLLAB

COLLECTIONS

WE ARE NORTH SAILS

ACTION SPORTS

Popular Search Terms

Organic cotton

Scuba fleece

Drawstring hood

Utility pocket

Stand collar

Sorry, no results for ""

Subscription

Welcome aboard.

We want to make our emails as relevant as possible for you.

Interests saved

Something went wrong, please try again

Welcome to North Sails

Stay up to date with the latest North Sails news.

Receive a 10% discount code for your first apparel order. Excludes sails and SUP’s. See our Terms and Conditions .

Yes, I agree to the terms of use and privacy policy.

J/105 TUNING GUIDE

Download the North Sails J/105 Tuning Chart

Part 1: Rigging Preparation

The following recommendations are small changes that should be made to the stock J/105 to allow you to get the most from your North Sails and make the boat easier to sail and set up.

Head swivel shackle

The North Sails jibs come with a webbing loop at the head. It is critical to have a 90-degree “twist” shackle to attach the sail to the swivel. A standard shackle will cause a hard spot at the top of the jib as the sail is torqued.

Remove backstay toggle

Many J/105s come with a toggle that rotates the hydraulic cylinder 90-degrees so that the handle faces forward. While it is nice to have the handle forward, this toggle reduces the throw of the backstay adjuster too much so that you are not able to get enough tension in heavy air. Some of the older boats actually need to have the backstay rod shortened to get enough backstay throw.

Change to 4:1 or 6:1 Cunningham

The standard Cunningham is 2:1 and led aft to a cabin house halyard stopper. This system should be replaced with the lower purchase with integral cleating shackled to the ring on the top of the Quik Vang. This allows for easier and more precise Cunningham control by a forward crewmember. Many boats then rig the asymmetrical tack line through the free stopper.

Mark the tack line at the cleat

Put marks on the tack line at the proper range of settings. As you approach the windward mark you can then pre-set the tack line so that when you extend the pole and set the spinnaker the tack will be set properly. The tack line is much easier to work with in this placement than on the side of the cabin house.

Move mainsheet swivel base forward of the traveler

This allows for easier trim of the gross tune by the main trimmer, especially when tacking.

Tapered Spectra spinnaker sheets

These sheets have a light uncovered portion that attaches to the sail, with a covered portion that goes on the winch. The sheets should be 3/8” Spectra cored line with the cover removed at the sail end of the sheet. These lightweight sheets are used in all conditions and help downwind performance in light air. Heavy sheets pull down on the leech of the spinnaker in light air, closing the leech too much.

Bypass the jib sheet turning block

The standard set-up for the jib sheet is to run the sheet from the clew of the jib, through the lead block, through the turning block near the rail, and then to the winch. This set-up makes the lead block lean over to leeward, increasing sheeting angle. In light and moderate air, the jib will sheet tighter to the centerline if you lead the sheet straight to the winch from the jib lead block. In heavy air, it can be faster to use the turning block to sheet the jib outboard slightly.

Part 2: Rig Set-Up and Preparation

Tools and items required: Loos RT 10M Rod Tension Gauge, 2 crescent wrenches, spray lubricant, bosun’s chair and 50’ metric tape measure.

Part of the success of growth of the J/105 Class is the tight class rules and limited sail inventory. With the J/105s limited sail inventory of only one headsail, aggressive rig tuning is essential for performance throughout the full range of wind conditions. By definition, the North Sails “AP” inventory is optimized for 9 to 12 knots. This is actually the easiest condition to sail in, so the racing tends to be at its tightest. Having really fast sails in this condition is key to gain a slight speed edge and the AP inventory is designed to give you just that. The heavy air “HA” inventory is optimized for 13-20 knots. In the extreme conditions of light and heavy air the rig must be manipulated to enhance the sail shapes for those conditions. The result of proper rig tuning is the correct relationship between mast bend and headstay tension to get fast shapes. The North inventory has been designed to make these transitions easily with the correct tuning to be fast in all conditions.

Step One: Check Mast Butt Position

The measurement from the front of the forward bulkhead to the aft face of the mast should be 24.46cm (9 5/8”). This is very close to the center of the step. For the HA sails, the mast butt should be 26.00cm (10 1/4”) from the bulkhead.

Step Two: Check J Measurement

The J measurement is the distance from the headstay intersection to the deck to the forward face of the mast. This should be a minimum of 4.11m (13’6”). Use mast chocks or SparTite to achieve this position.lean over to leeward, increasing sheeting angle. In light and moderate air, the jib will sheet tighter to the centerline if you lead the sheet straight to the winch from the jib lead block. In heavy air, it can be faster to use the turning block to sheet the jib outboard slightly.

Step Three: Set Mast Rake

Rake is controlled by headstay length. The headstay should be set at the class legal maximum rake, 13.035m (42’ 9.125”). Hoist a crewmember up the mast and have them hold the butt of the tape measure at the center of the pin that secures the forestay to the mast. Measure to the to of the furler drum (measurement A), then measure from the top of the furler drum to the bottom of the furler drum (measurement B), then from the underside of the furler drum to the intersection of the stem and sheer line of the boat (measurement C). The overall headstay measurement is then the sum of A+B+C.

Step Four: Centering the Spar

Put a mark on the rail of the boat on one side even with the chainplates. Measure this distance from the headstay attachment on the bow. Put a corresponding mark on the other side, the same distance from the headstay. At this point the Upper Shrouds (Caps) should be hand tight and the Intermediates (D2s) and the Lowers (D1s) should be loose. Hoist the tape measure to the top on the centerline jib halyard. Measure to the marks on either side and adjust the Caps until they are equal.

Step Five: Tensioning the Shrouds

Tighten the D2s and D1s to hand tight. Add 8 full turns to the Caps. Then tighten the D2s 6 turns. This should be done incrementally (2-3 turns at a time per side) sighting the mast to be sure that the mast is in column. Add turns to one side and remove turns from the other to bring the mast in column. This added tension that you have applied has probably made the D1s slack, so double check to make sure that they are hand tight.

Step Six: Check Shroud Tensions with Loos Gauge

Put marks on the shrouds 2m (6’ 6 3/4”) up from the deck. Put the top post of the gauge on this mark when measuring tension. Be sure to have the backstay released when measuring tension with the Loos Gauge. For the base setting for 10-14 knots TWS the shrouds should read the following:

All Purpose Sails Caps: 35 D2s: 10 D1s: 0 (10 cm play)

Heavy Air Sails Caps: 55 D2s: 25 D1s:10 (hand tight)

You should double check to be sure that the mast is still in column at the dock when the rig is at full tension. At the base setting, the mast should sit with virtually no pre-bend up to the hounds.

You are now at the “base” setting and ready to go racing. From here follow the Quick Tuning Guide to optimize your J/105’s performance for various wind conditions.

Advanced Tuning – Beyond the Numbers

The North Sails J/105 Tuning Guide is very refined, and has been used to the letter to win many events. However, understanding the fundamental concepts of how tuning affects the rig and sails is important to be able to check that the settings are right for your boat, as well as customizing your own tuning numbers for your sailing style. Keeping good records is the key. Keep a Wet Notes pad on your boat and record your rig settings, wind speed, sea state, and your speed and pointing relative to other boats. This will help you to see what is working best for you and fine tune your own numbers.

Changes to shroud tension affect the rig in two ways: 1) headstay tension & 2) mast bend. Tighter Cap shrouds generate more headstay tension by pulling back against the headstay. A good guide for Cap (upper) shroud tension is that the leeward Cap shroud should just go slack in all but the heaviest of wind conditions. Tighter D1 (lower) and D2 (intermediate) shrouds generate more headstay tension by reducing mast bend and compression. The important factor of the D1 anD2 adjustment is the relationship to the amount of backstay used in each wind condition, which affects mainsail shape. Tight D1s and D2s will make the mast too straight (main too full and draft forward) when no backstay is used, and conversely loose D1s and D2s will allow the mast to bend too much (main too flat or even inverted) when a lot of backstay is used. The final D1 and D2 rig tension will be dictated by mainsail shape.

The light air performance of the J/105 can be dramatically improved with leeward mast sag in under 12 knots. This is side-to-side sag from the partners to the hounds. This can only be seen under sail and will not happen at the dock. The settings from the Quick Tuning Guide should generate this sag, but all masts are a little different, so you may need to adjust your intermediates and lowers to achieve it. Loosen the intermediates and lowers so that there is 2.5cm (1”) of leeward sag halfway to the hounds in under 9 knots and Zero in 9-12 knots. In general the intermediates will need to be eased twice as many turns as the lowers to achieve even sag.

Part 3: Mainsail Trim

The J/105 relies on much of it’s power from the mainsail with the class inventory. The mainsail is very easily adjusted because there are many shape controls including mainsheet, traveler, backstay, cunningham, vang and outhaul. Proper mainsail trim is achieved by balancing the speed and pointing with its twist, angle of attack and overall power. Proper communication with the helmsman for the feel of the boat and performance vs. the boats around you are the key to establishing the correct balance of those three elements.

Mainsail Angle of Attack — The Traveler

The traveler controls the boom angle to the centerline of the boat, which is described as angle of attack to the wind. Much like the sheet, a narrow angle of attack (traveler high) is used for pointing and powering up the boat and a wide angle of attack (low traveler) is used for acceleration and depowering the boat. Carry the traveler as high as possible without making the boat heel too much.

In light to moderate conditions the boom should be on centerline or slightly above. In very light air, when the main is twisted, setting the boom actually above centerline will put the lower third of the main parallel to the centerline of the boat. A good gauge for this is to look where the bottom batten is pointing. The bottom batten should point at the backstay in very light air. If it is pointing to windward of the backstay, the traveler is too high.

As the breeze builds, the traveler should be played aggressively to control heel and keep the boat on its feet. If the boat heels too much, the boat will get too much helm and the helmsman will have to use much rudder angle to keep the boat going straight. The optimum rudder angle to create the most lift is around 4 degrees. There are times when more angle than that is unavoidable, but 5 degrees of rudder angle should be the most that you try to use. Rudder angle can be monitored by putting a tape mark on the top of the wheel when it is perfectly straight. The main trimmer can notice when the helmsman is using too much helm (or not enough) and adjust the traveler appropriately.

Mainsheet vs. Traveler for Various Sea States

One of the more difficult things to determine is how to depower the main in moderate to heavy conditions. As we have learned, you can depower the main by either twisting the main by easing the sheet or letting the traveler down. The technique used should be determined by sea state, which will affect how the helmsman has to steer the boat. In flat water, the helmsman should be able to use very subtle steering changes. Hours of on-the-water testing has shown us that depowering by lowering the traveler and keeping a tight, untwisted leech produces the best VMG. You can point reasonably high in flat water without slowing down and the tight leech will help with pointing. We have found that twisting the main in flat water in moderate air only makes you lose height. With this style the traveler is played to maintain the proper angle of heel. However in waves and chop, the opposite has proven to be faster. In waves and chop the helmsman has to be more aggressive with the helm. With the wider range of steering keeping the traveler higher (with the car near centerline) with a more twisted main allows the helmsman to steer through wider angles and accelerate as needed in the waves. With this style the mainsheet fine tune is played to maintain the correct trim and angle of heel as the helmsman steers through the waves.

Overall Power – The Backstay

The backstay is the most important sail control for setting the overall power of the sail plan. The backstay is the universal control to modify the shape of the main primarily, but also the jib. The North Class Inventory has been carefully designed so that backstay adjustment changes the shape of the main and jib in unison. As backstay is applied the mast bends, flattening the main. It also pulls aft against the headstay, reducing headstay sag, which flattens the jib. By flattening the sails the boat’s power is reduced as the boat becomes overpowered and heels too much. Flatter sails can be trimmed harder than full sails so when it is windy it is better to set the sails up flatter and sail with less twist. This will allow you to point higher.

As stated in the tuning section of this guide, having the rig set up properly for the wind conditions will allow you to get the most benefit of adjusting the main and jib together with the backstay, but it is also the control that allows you to set up the sails as best you can when the wind changes and you are no longer tuned correctly.

With a loose rig the main will flatten out faster than the jib. This is because the loose D1s and D2s will allow the mast to bend, which will flatten the main. However, since the mast is bending, the main will get to a point where it over bends before you can bottom out the backstay. By not being able to bottom out the backstay, the jib will still be a bit fuller than is ideal at this point since 1) you can’t pull on the full range of backstay and 2) the mast will compress more so the backstay tension will not transfer as well to the headstay.

Conversely, with a tight rig, the main will stay fuller when the backstay is eased, while the overall rig tension will keep the headstay tighter and thus keep the jib a bit flatter. It is important to understand this relationship between how the backstay and rig tuning affects sail shape when you may not be tuned correctly. If your rig is too loose, use more backstay to set the main up flatter, knowing that your jib will be fuller than ideal. If your rig is too tight, use less backstay to set the main up fuller, knowing that your jib will be flatter than ideal. In general, it is better to be set up with a flat main and a full jib so it is better to err on the loose side of the rig tuning matrix if you expect the wind to change. It’s much easier to depower the J/105 than it is to power it up so always tune for the lulls!

As the mast bends it has an immediate effect on the luff and leech tension, so other controls must be adjusted in conjunction with the backstay. When you pull the backstay on, the mainsail will twist more so more sheet will have to pulled on to reset the twist. More backstay will also loosen the luff, so more cunningham will be needed. Don’t forget to ease the sheet and the cunningham after you ease the backstay.

Other Mainsail Controls

Cunningham he cunningham controls the luff tension of the mainsail. Luff tension controls the draft position of the mainsail. As backstay tension is applied, the mast compresses and the main appears to fall down a little and the draft will move aft. Pull on the cunningham to move the draft forward to the desired position. As well as moving the draft, luff tension will also make the main somewhat flatter. In light air, you should see slight wrinkles coming from the sail slides. In moderate air the luff should be smooth. In heavy air, the luff should be tensioned past being smooth to set the draft position and flatten the sail.

Vang With the non-overlapping jib, in order for the mainsail to generate enough power in light air, a certain amount of depth has been designed into the lower portion. In over 12 knots begin to pull on the vang to induce low mast bend to flatten the lower third of the main. When it is really windy pull on the vang quite hard to help bend the mast. be sure to ease the vang at the weather mark! Before you ease the main, ease the vang to allow the main to twist as you bear off. If the vang stays on too hard, you may not be able to bear away, or worse you could break the boom.

Outhaul The outhaul also controls the sail shape in the lower third of the mainsail. Easing the outhall makes the lower third of the mainsail fuller and tightening flattens the lower third. In light air the outhaul should be slightly eased and pull it progressively harder as the wind increases, to the point where you should pull it as hard as you can in over 15 knots.

Part 4: Jib Trim

The J/105 Class Jib has a very tough job. It has to be fast in all wind conditions, where other 35’ offshore one-designs allow three headsails! The single jib inventory presents a tough challenge for sail designers to create a sail that is versatile enough to cover the entire wind range, while being constructed so that it can be light enough to perform well in light air, yet being strong enough to handle heavy air. The 3DL jib is the ultimate solution to handle this daunting task. The latest design has been refined to be responsive to the few controls that can change the shape. The 3DL process is the only way to create a sail that is minimum weight, yet is strong enough for heavy air.

While the North 3DL jib is refined to a level that makes it very easy to enhance the light shape in light air and a heavy shape in heavy air, it is important for the trimmer to be able to manipulate the sail appropriately. The primary controls that we have to affect the sail shape are the halyard, sheet, jib lead placement and headstay tension.

Jib Halyard

The halyard is the most important sail control for shaping the jib and it has a much greater affect on sail shape than the cunningham on the main. However, just like the cunningham on the mainsail, the halyard controls the entry angle, draft position, and overall depth in the sail. A tighter halyard will produce a more draft forward, rounded entry shape, with less overall depth. A loose halyard will produce a more draft aft, finer entry shape with more overall depth. As a general rule, the halyard should be tensioned to just barely remove the wrinkles in the luff. In lighter air wrinkles can just be visible, in moderate air the luff should be smooth, and in heavy air the halyard should be pulled 2.54-7.62cm (1-3”) past removing the wrinkles.

In flat water, a looser halyard can improve pointing with a finer entry angle. In waves and chop, a tighter halyard will produce a more rounded entry and more open leech, which will have a wider steering groove and be better for acceleration. If you try the loose halyard and your helmsman seems to be struggling to find the groove, try a slightly tighter halyard.

As sails age, the entry tends to get finer and the draft starts to move aft. An older sail will require more halyard tension to achieve the same shape as a brand new sail with a looser halyard.

The sheet is the most important control for adjusting the jib once the draft is set. The general rule is to trim the jib as hard as possible without slowing the boat down too much. The jib needs to be played in conjunction with the main and the helmsman’s steering. The sheet tension will change with each change in the wind speed. When a puff hits, the leech will become more open. Be careful not to trim the jib too soon. Allow the leech to stay open to take advantage of the puff to accelerate the boat and them trim in once you have accelerated to increase pointing.

The Class mainsails are fitted with a spreader window so that you can see the jib leech on the lower spreader. Put tape marks on the spreader at 7.62cm (3”), 15.24cm (6”) and 22.860cm (9”) in from the spreader tip. In general you should trim the jib so that it is at the spreader tip in very light air, 7.62cm (3”) inside the tip in light air, 15.24cm (6”) to 22.860cm (9”) inside the tip in moderate air, then back out to 7.62cm (3”) in heavy air. These guidelines are subject to change based on sea state. The jib can be sheeted harder in flat water than in waves and chop. Be careful to only make small sheet adjustments. Due to the high aspect nature of the jib, small changes make a big difference.

The jib lead should be used to control the top and bottom shape of the jib. The middle of the jib is not as affected by lead position as much as it is with sheet. Once the sail is trimmed to the appropriate spot on the lower spreader, adjust the lead to make the top and bottom look right. Moving the lead forward will make the upper leech more closed and the foot rounder. Moving the lead aft will make the upper leech more open and the foot flatter.

The median jib lead position is slightly aft of the middle of the jib track, which is about 9” aft of the chainplate. This position is also just forward of the window on the side of the cabin house.

Headstay Tension

Headstay tension has the most dramatic affect on the overall camber of the jib. Headstay tension affects headstay sag. This is a difficult thing to visualize, but it works much the same as mast bend affects mainsail shape. As the headstay sags, it pushes the luff towards the leech, which increases camber. Conversely as the headstay gets tight, it pulls the luff away from the leech, decreasing camber.

Clearly this is very important, but has been listed last here because it is very dependent upon rig tuning. Headstay tension is achieved by a combination of a tighter rig and a tight backstay. As we have learned in the rig tuning and main trim sections, rig tuning and backstay tension has a great affect on mainsail camber as well. The Class main and jib designs and the tuning guide shroud tensions have been carefully developed to have the backstay control main and jib camber in unison. If you are tuned properly, when the main sets up correctly, the headstay tension will be correct as well. Your headstay tension should be almost self-tending.

During a race, the only way to adjust your headstay tension is with the backstay. Because of this it is important to know how you are tuned and whether you are actually sailing in the right wind speed for your tuning. The backstay will be the key to get the most of the set up that you have when you are not tuned perfectly. Simply, if there is less wind than you are tuned for, use less backstay tension to power up the sails as best you can. If there is more wind than you are tuned for, use more backstay tension.

A good technique is to tape a batten with marks every 2.54cm (1”) on it to the backstay cylinder. This will help you to be able to record your settings and duplicate them later.

Part 5: Crew Weight Placement

With the new “float line” rule, this discussion has become much easier now that we know that all boats should float the same. The goals of weight placement are to 1) control helm and 2) reduce wetted surface in light air.

In light air the crew should be well forward and to leeward both upwind and down. Two crewmembers should be forward of the shrouds to leeward. Remaining crew should be up near the shrouds. There should only be one person in the cockpit other than the helmsman. In really light air the main is not trimmed that often and the helmsman can make small adjustments. Being to leeward helps heel the boat increasing helm giving a better feel and allows for the best pointing and rudder lift. Being forward allows the bow to dig in which also helps pointing as well as reduces wetted surface by getting the transom out of the water.

Moderate Air

In moderate air the crew can begin to slide back as they begin to move to weather. Once anyone goes to weather they should be stacked just behind the shrouds. At this point if you have a dedicated main trimmer, he can slide back to his station upwind. Downwind as soon as there is constant adequate pressure on the sheet and you begin to try to sail low the crew should move to weather to help rotate the spinnaker to windward out from behind the main. This happens at about 10 knots. There is plenty more coming on downwind sailing in Part 6, starting on page 21.

In heavy air the crew should continue to move aft, especially in waves. If you notice that your helmsman has to steer a lot to keep the boat going straight (dialing for dollars), move aft and as the bow lifts the boat will track straighter. Since crew weight is limited the guys who are on the rail need to hike hard. Remember, sailing is a sport and it’s a boat not a couch!

Part 6: Downwind Sailing

Sailing the J/105 downwind can be one of the more difficult things to do well. Paying small attention to the minor details can make a huge difference. The key to fast sailing downwind is good communication between the trimmer and the helmsman. The trimmer should constantly be telling the helmsman how much pressure he has in the sheet. This will allow the helmsman to know if he can bear off a little more, but more importantly when he needs to head up a little bit to build pressure.

The J/105 has an asymmetric spinnaker set on a centerline sprit. The goal in downwind sailing is to maximize downwind VMG. This is achieved by sailing a wind angle tight enough to keep speed, but sailing lower towards the mark whenever possible. The North Sails asymmetric has been designed as a running spinnaker for optimum downwind performance at the apparent wind angles that produce the best VMG for the J/105. The sail has been designed to rotate out to windward to project the maximum sail area out from behind the mainsail. Always hoist the sail all the way to the top. Due to the luff length restriction in the rules, the tack of the sail is never set all the way down to the pole. Raising the tack helps the sail to rotate to windward.

Light Air Sailing (0-9 knots TWS)

In light air, you must sail tighter angles for best VMG. The tack is set 0.3m-0.6m (1-2’) off the sprit. The crew should be forward and to leeward. Keep the crew weight as low as possible. Steer down in the puffs until the pressure sheet starts to get light and then head up slightly. Communication between the trimmer and the helmsman is key. Try to find the lowest angle you can sail before the speed drops. Don’t forget about the main! Proper mainsail trim is essential to good speed. The vang should be set so that the top batten is open by 5 degrees. A good trick to help acceleration out of the jibes is for the main trimmer to hold the sail in a bit after coming out of the jibe. When the asymmetric is jibed, it needs to

be overtrimmed to make it “pop” through. When the spinnaker is overtrimmed, it blows air back into the mainsail relieving pressure from it. By keeping the main in, it will keep the main pressurized as well as opening the slot between it and the spinnaker to get the air flowing over it faster. The main trimmer can easily feel if the main is pressurized by the pull on the sheet. Ease the main out slowly as the pressure on the sheet builds as the spinnaker is eased.

Moderate Air Sailing (9-12 knots TWS)

In moderate air, there is a wide range where you can sail. Lower is best as long as you can maintain your speed. The tack line is eased 0.6-0.9 (2-3’) off the sprit. The same principles apply to steering as in light air. Once the boat feels well pressured, the crew should move to the windward side to help rotate the spinnaker. In this range the crew should be very active moving to weather when you head down in the puffs and back to leeward when you head up in the lulls.

Heavy Air Sailing (12+ knots TWS)

In over 12 knots, the boat is well pressured up going downwind. At this point you want to sail as low as possible most of the time. There will almost always be good pressure on the sheet but when you sail too low, the sail will become blanketed behind the main and collapse. The sheet is well eased to get as much of the sail out from behind the main as possible. The crew should be to windward at all times. Heel the boat to windward by as much as 10 degrees. The vang should be set so the top batten is parallel to the boom.

DOWNWIND NOTES Good coordination between the trimmer and helmsman will result in very subtle changes in the sheet. A properly coordinated team will only adjust the sheet by a couple of feet. If you find yourself constantly trimming and easing more than 3 feet of sheet than your coordination should be improved. Be careful not to try to sail too low and collapse the spinnaker. A collapse will result in around a three-boat length loss!

GET IN TOUCH

REQUEST A QUOTE

BROWSE ALL SAILS

FIND YOUR SAIL

Featured stories.

07 September

AEROTECH: A REVOLUTIONARY HIGH-PERFORMANCE WOVEN DOWNWIND SAILCLOTH

06 September

BIGGER BOATS BUT THE SAME SKILLS

05 September

NORTH SAILS PARTNERS WITH SAFE HARBOR MARINAS

- Refresh page

- J/Boats Home

- Brokerage Listings

There is a reason the J/105 is the largest one design class of racing sailboats over 30' feet long. J/105's are fun to sail! whether it's a jaunt around the lake, or up the coast with family and friends or around the race course the J/105 is a lot of fun. Fast and friendly. This 1992 J/105 has the early layout with the Nav table located aft. It's a pre-scrimp boat. Hull #23. These early pre-scrimp J/105's are selling up to $100,000 when re-furbished. This J/105 has just completed a complete restoration. The bad core was replaced with OEM core with each individual cube sealed with epoxy and then vacuum bagged to make a "better then new" repair. This process was used on the deck and the hull where needed. The deck has new non skid in smoke grey. The hull topsides are new white awl grip and the bottom has new baltoplate bottom paint. The mast, boom, and spreaders have been stripped and painted with an aircraft grade etching primer and top coated in white awl grip. The wheel has been powdercoated in white. There's a BUNCH of sails that are included with the boat. The newest suite of sails are from UK and were only used one weekend. Triad Triple axle trailer available for an additional $10,000.

Make or Manufacturer

Length overall, length at waterline, displacement, fuel capacity.

Electrical Equipment

Electrical Circuit: 12V

Manufacturer Provided Description

J-105 gives the on-deck cruising comfort of a 40-45-footer and the speed of a Grand Prix racer. Though designed as a strict one-design for recreational fun with overnight capability, Sailing World's panel of experts selected her as the "Racer - Cruiser" Boat-of-the-Year for 1991 and 1992. With J-105, sailing is easier and smoother. No pitching, no rolling about and no panic drills. A sailor may never have to leave her comfortable cockpit. No feverish routines of course and sail changes. Only one jib to tend. Roll it in or out. Jibing this high-tech beauty is a one-person operation. Simply let go of the old sheet, then trim in the new one. Good-bye big racing crews. Hello fun and relaxation. J-105's asymmetric spinnaker enables reach at a fast 90-degree apparent wind angle, while actually sailing a deep 155 degrees from the true wind. The carbon-fiber bowsprit retracts. Whether blowing 5 mph or 20 mph, J-105's asymmetric spinnaker adds a whole new dimension to sailing enjoyment in five ways: 1) it's safer - less deck clutter plus total snuffing or partial quick-reefing from the cockpit; 2) it's easier - one person controlling all sails; 3) it's smoother, with a better-balanced sail plan which helps in steering out of trouble; 4) it's stiffer due to the spinnaker's lower center of area and flat, open leech; and, 5) it's faster over waves, thanks to the power and lift of this unique spinnaker design. Sailing trials in adverse weather conditions clearly demonstrated the superior handling qualities of this design. The Dacron mainsail on sailslides, a single roller-furling jib, the dodger and spinnaker-in-a-snuffer make this design easier to sail, quicker to stow and more fun to own than conventional racers and cruisers.

Equipment List